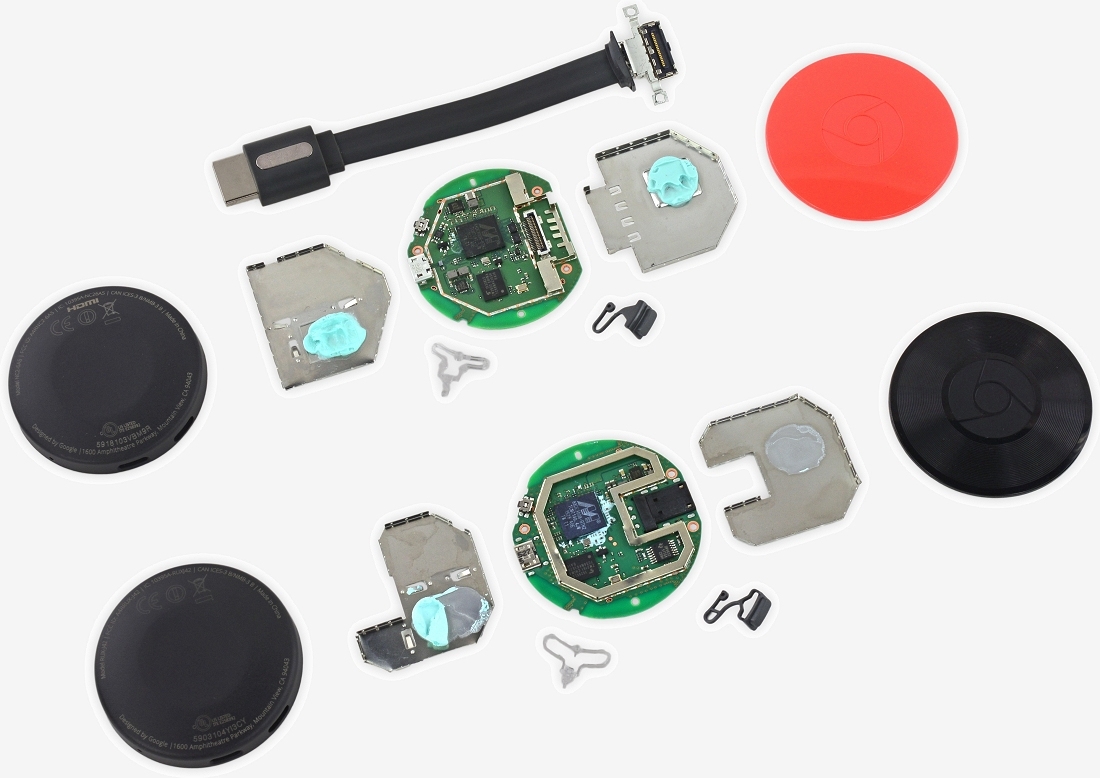

Google unveiled a pair of new streaming media accessories last week. Both the second generation Chromecast and Chromecast Audio unitize a unique form factor that’s wildly different from its first HDMI dongle. According to iFixit, there’s a good reason for the design change.

The original Chromecast was known to run on the warm side, an issue that likely played a role in the new design.

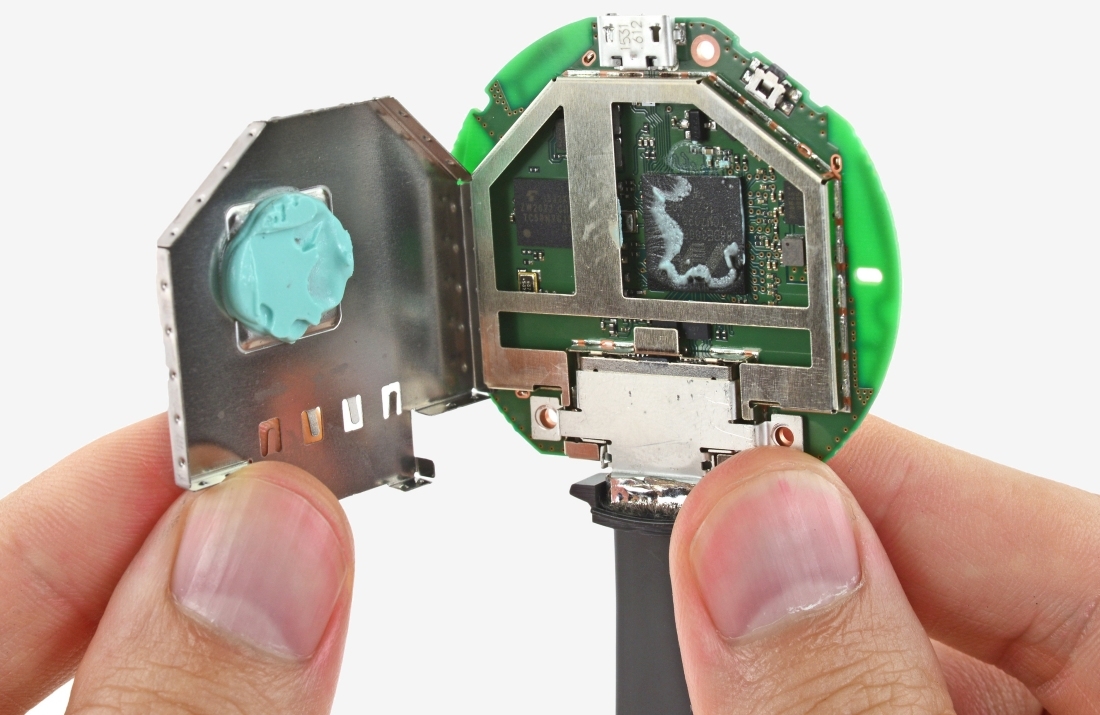

Once the teardown specialists got the outer cover removed, they found a large (relatively speaking) EMI shield covering the motherboard. On the underside of the EMI shield was a large gob of thermal paste. iFixit found another helping of thermal paste under the second EMI shield as well as on the reverse side of the motherboard between it and the bottom of the chassis.

Although the new Chromecast wasn’t advertised to support 4K video, Google did say it planned to add new features in the near future. Unfortunately, 4K video won’t be one of them as the Marvell Armada 1500 Mini Plus processor tops out at 1080p resolution at 60 frames per second.

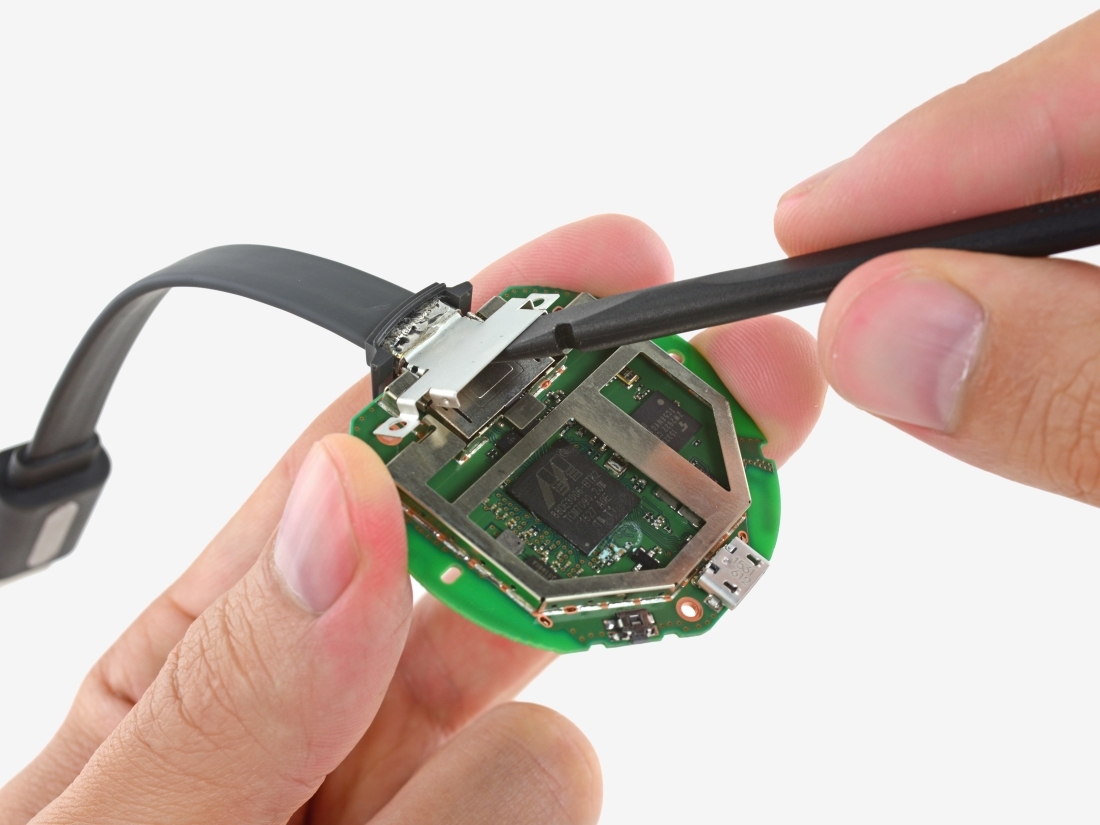

It’s not a total loss, however, as iFixit loved the internal detachable HDMI cable as it addresses what is likely to be its most common problem – a damaged or loose HDMI connection.

The electronic surgeons also disassembled Google’s Chromecast Audio. The design is very similar internally, iFixit said, as some of the chips are the same as what was found in the video streamer. The big difference, of course, is the inclusion of some audio-specific ICs.

iFixit didn’t assign a repairability score to either device as there simply isn’t much to repair in the event of an internal hardware failure.

All images courtesy iFixit

https://www.techspot.com/news/62359-gobs-thermal-paste-prevent-new-chromecasts-overheating.html