Researchers at Harvard’s Wyss Institute for Biologically Inspired Engineering and the John A. Paulson School of Engineering and Applied Sciences (SEAS) have created a 3D printer that’s capable of printing complex metallic objects in midair.

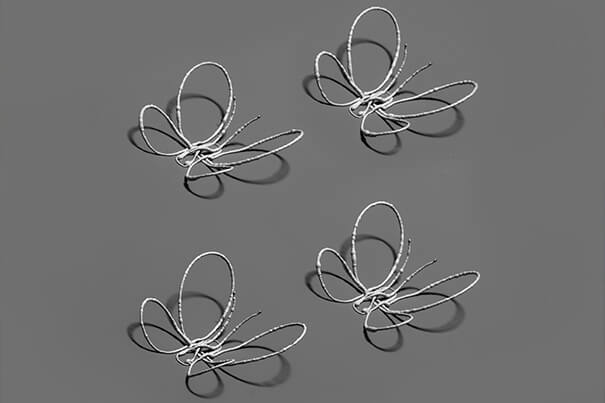

Traditional 3D printers work by extruding filament – typically either PLA or ABS – layer by layer, building the print from the ground up. In contrast, this new method, dubbed laser-assisted direct ink writing, prints microscopic, free-standing silver nanoparticle structures.

The heated silver is extruded and immediately hit with a programmed laser that anneals the metal using just the right amount of energy. The printing nozzle can move on X, Y and Z axes which, when combined with the rotating print stage, enables freeform curvature.

Wyss Institute Postdoctoral Fellow Mark Skylar-Scott, who is the first author of the study, said the most challenging aspect during development was dialing in the exact nozzle-to-laser separation distance.

If the laser gets too close to the nozzle during printing, Skylar-Scott said, heat is conducted upstream which clogs the nozzle with solidified ink. To solve this issue, he said they came up with a heat transfer model to account for temperature distribution along a given silver-wire pattern. This allowed them to modulate the printing speed and distance between the nozzle and laser to control the annealing process on the fly.

The technique could one day be used to create custom electronics like wearables and medical devices.

https://www.techspot.com/news/64905-3d-printer-uses-lasers-silver-nanoparticles-print-midair.html