In context: Manufacturers are trying to develop novel chip substrate technologies to save Moore's law and keep crunching the Megahertz rates up. Glass is the most promising material for next-gen substrates Manufacturers should start using them earlier than anticipated – if Samsung can succeed at its ramped-up R&D effort.

According to rumors from unnamed industry insiders, Samsung has decided to invest heavily in the research and development of glass substrates for chip manufacturing. The company plans to bring products to customers by 2026, creating a "coalition" of subsidiary organizations to speed up technology development.

The leakers say that three divisions within the Korean conglomerate – Samsung Electro-Mechanics, Samsung Electronics, and Samsung Display – will develop the new glass-based chip substrates. Samsung Electronics will work on integrating semiconductor components with the new substrates, while Samsung Display and Electro-Mechanics focus on the glass processing part.

The insiders said that Samsung will try to leverage a synergic approach among its subsidiaries, leveraging their expertise in their respective fields. During the Consumer Electronics Show 2024, Samsung Electro-Mechanics announced plans to build mass-production capabilities for glass substrates by 2026.

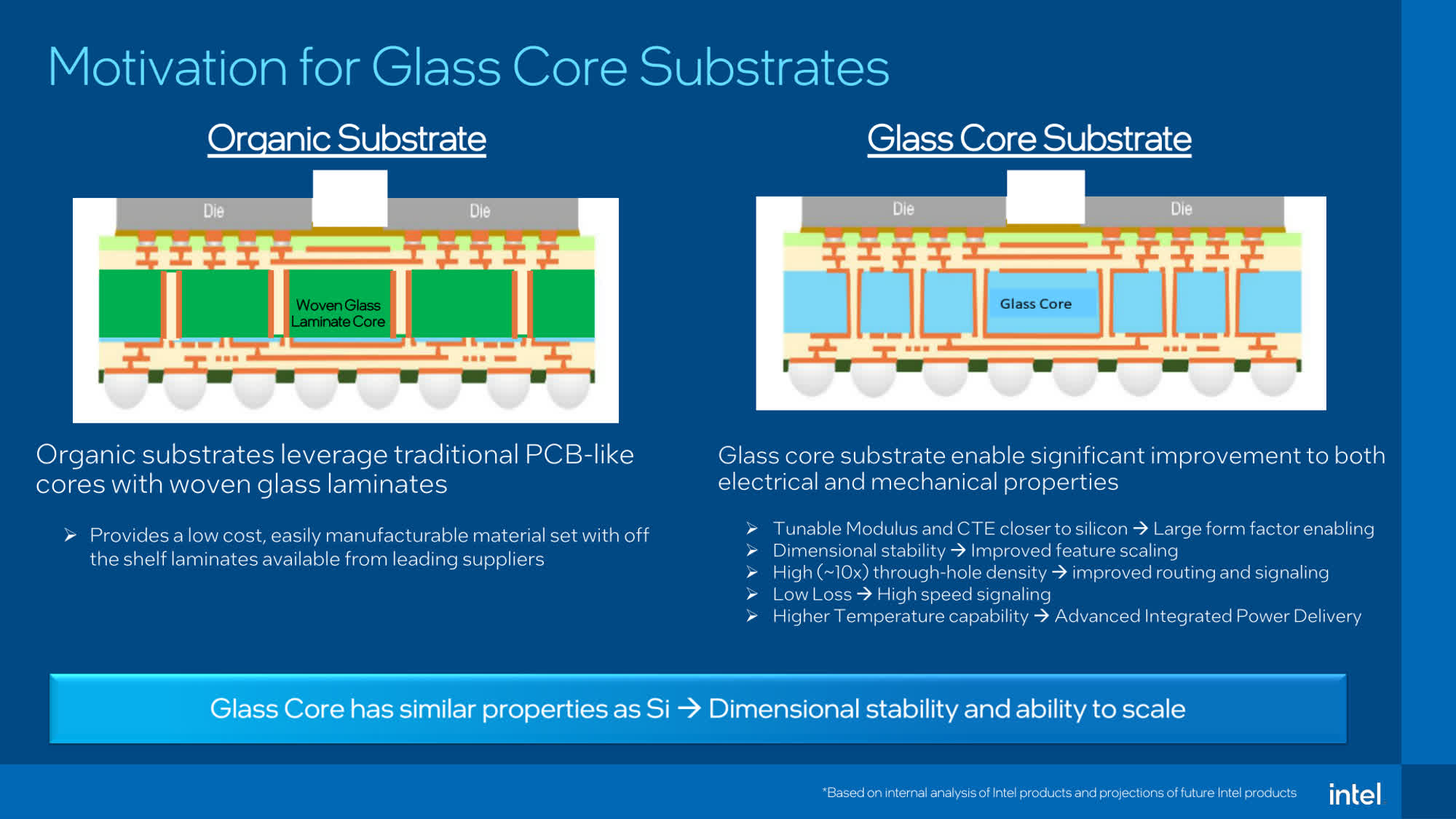

Glass substrates can theoretically bring significant improvements to the chip manufacturing process. Compared to traditional organic substrates, glass shows an enhanced flatness that improves the depth of focus for lithographic processes. The material also has higher dimensional stability for interconnects and provides higher thermal and mechanical strength.

The material could withstand higher temperatures and stress levels, making chips more durable and resilient even in "harsh" data center conditions. The technology would be ideal for multi-chiplet, system-in-package (SiP) applications, which are set to become one of the industry's most popular chip designs. Intel has been developing a glass substrate solution for years, and the company recently announced its plans to launch novel commercial products by 2030.

Samsung and Intel aren't the only companies working on the next generation of substrate technology. Japanese manufacturer Ibiden has also joined the R&D effort for glass-based designs, while South Korean company SKC has opened a new subsidiary (Absolics) to develop new mass production capabilities. Absolics has already partnered with AMD and other leading semiconductor companies.

https://www.techspot.com/news/102286-samsung-wants-bring-chips-glass-substrate-market-fast.html