In context: The options for destroying a hard drive have left much to be desired. Melting it can cause toxic chemicals and e-waste, shredding it can release environmental contaminants, too, and drilling still leaves the door open to partial data recovery. Garner is offering a solution, or rather, two solutions. First, run the hard drive through its upcoming super degausser, called the DeMag. Then, insert the hard drive into the DiskMantler to have it taken apart.

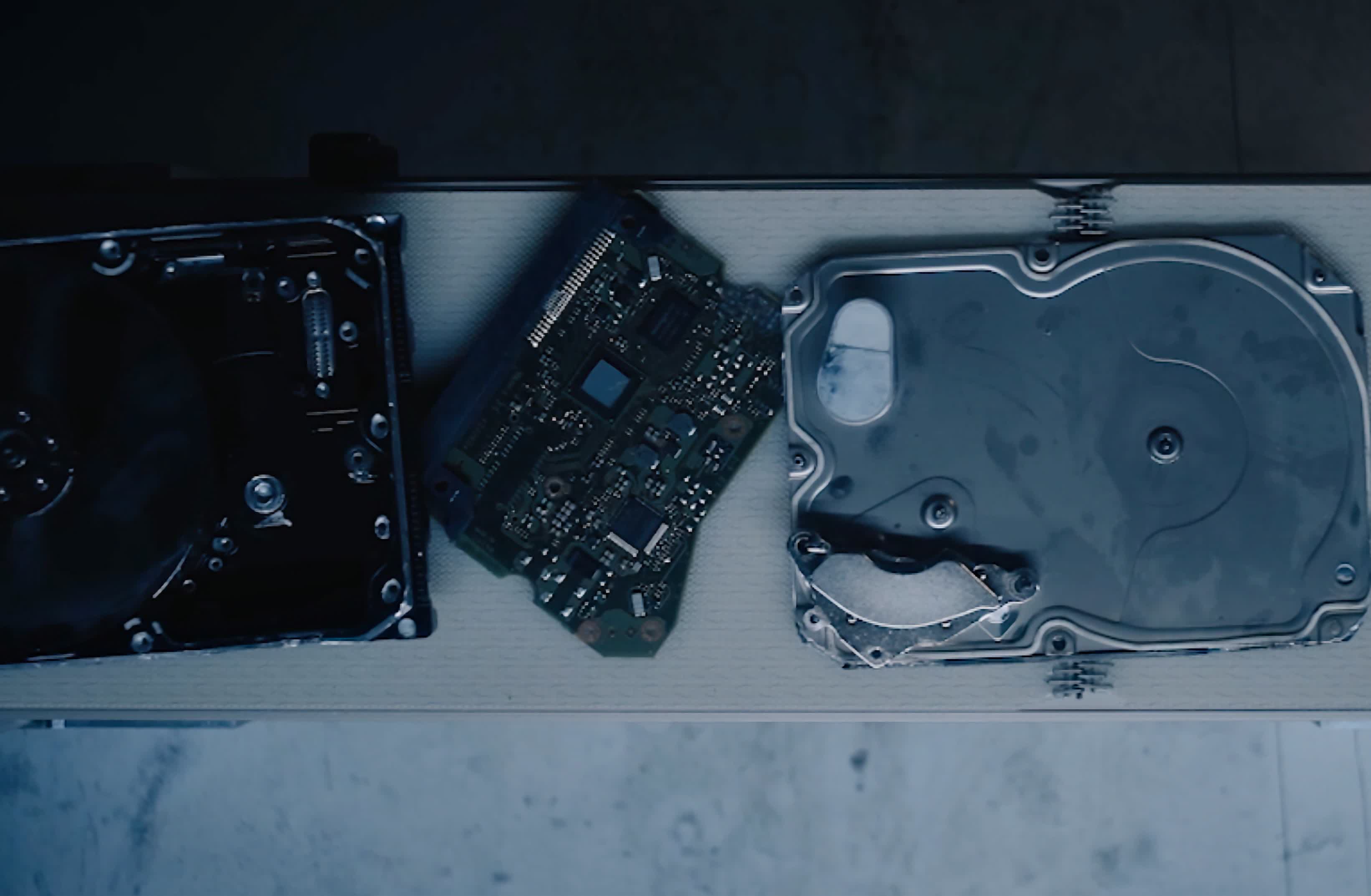

Data elimination company Garner has introduced the DiskMantler, a product measuring 24 inches x 15 inches x 45 inches, designed to disassemble decommissioned hard drives and separate the valuable internal components, such as rare earth metals, from the casing. This is achieved by vigorously shaking the device through a process involving shock, harmonics, and vibration that lasts anywhere from 60 to 90 seconds.

According to Garner, it only takes eight seconds for the greenboard to be separated from the HDD assembly. The disassembly time can be adjusted from eight seconds to 120 seconds, depending on the desired level of component separation, using a dial located at the front of the unit.

The actual disassembly process appears straightforward. You insert the HDD into the media slot either manually or by using the product's conveyor belt system. The internal automated system then carries the HDD into the disassembly chamber. Once complete, the recyclable components shoot out through the exit slot.

The goal is to reduce e-waste by saving these components for recycling and to provide a more sustainable, not to mention safer, alternative to traditional shredding and melting methods. While HDDs operate at a temperature of 55 degrees Celsius, melting one requires significantly higher temperatures of 670 degrees Celsius or more, a process that emits toxic chemicals and destroys the rare-earth materials.

The ability to reduce e-waste is a significant selling point for the DiskMantler, as it addresses a serious problem worldwide. According to the UN, the rate at which e-waste is generated is five times faster than the rate at which it's being recycled using documented methods.

Security is a concern when HDDs are shredded, as hackers could still recover enough data from the scraps for malicious intent. However, if a cybercriminal is able to glean data from leftover shreds, they would have a field day with the intact vibrated data platter that the DiskMantler will produce.

This is where another Garner product, the DeMag, comes in. Not yet available on the market, it acts as a super degausser that demagnetizes the HDD disk platters of all data and demagnetizes the magnets within the drive, making the data forensically unrecoverable. In addition, the rare-earth magnets within the drive no longer adhere to one another or other objects, which makes handling these materials more efficient.

With the HDD properly degaussed, it's ready for the DiskMantler, Garner says.

The DiskMantler can take apart a hard drive in as little as 8 seconds by vigorously shaking it