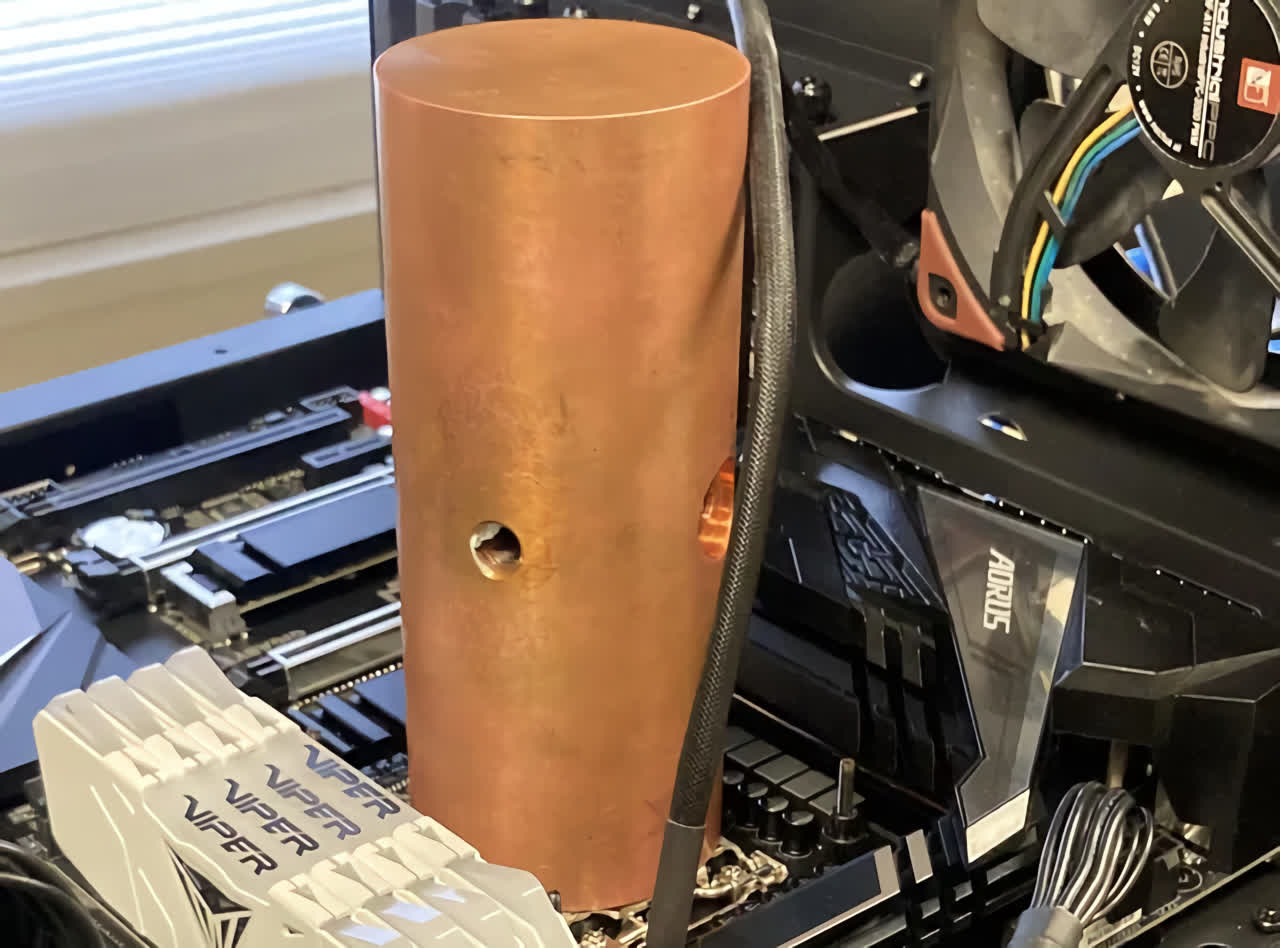

WTF?! There are plenty of unconventional ways to keep your PC's processor cool, like using a massive, 8-pound piece of copper that sticks up from the motherboard like a lighthouse, for example. It might sound ridiculous, and the method seems impractical, but it does work pretty effectively.

Redditor That-Desktop-User posted their DIY solution on the HardwareGore subreddit. The copper cylinder is being used to cool an unnamed Intel Core i9 CPU in a fully open-air system.

It sounds as if the thermally conductive material does a good job of passively cooling Intel's CPU. The i9 chips are known for getting very toasty, but the copper keeps it at 35 degrees centigrade (95 degree Fahrenheit) while idle. Running a stress test for under a minute caused the temperatures to jump to 80 Centigrade (176° Fahrenheit), and it took just ten seconds after the test was finished for the CPU to return to its idling temperature.

That-Desktop-User explains that they got the block from an old medical machine used to stimulate a person's vitals they bought for a few thousand dollars. The copper cylinder may have previously functioned as a cooler in the device as it has holes in the sides threaded for liquid flow. They believe it was originally used for nitrogen and oxygen and that it would be pretty easy to switch out the original 2-4mm (inner diameter) fittings for larger-diameter piping.

Some pieces of information are missing from the post, such as how the cylinder was fastened to the motherboard and what thermal paste was used.

Copper is a component found in many modern heatsinks, though not 8 pounds of it inside one cooler. The closest comparable product that comes to mind might be Thermalright's chunky, 4.1-pound True Copper passive heatsink from a few years ago.

Copper is a fairly expensive material, though work is being done to make it atom-thin, which could eventually be used to replace gold in chips, thereby lowering their build price.

https://www.techspot.com/news/97505-8-pound-copper-cylinder-can-cool-cpu-pretty.html