Pushing the limits: Enthusiasts are always looking for an edge in the world of overclocking and extreme cooling. In this wild test, the team sought to determine whether advanced GenAI and 3D printing could help them squeeze out more performance from today's processors. To answer this, they built a liquid nitrogen (LN2) container in a whole new way – and arrived at some interesting conclusions.

The project brought together experts from across the ecosystem – Skatterbencher who's renowned for overclocking prowess; Diabatix, specializing in generative AI for thermal solutions; 3D Systems for additive manufacturing; and finally ElmorLabs for overclocking gear.

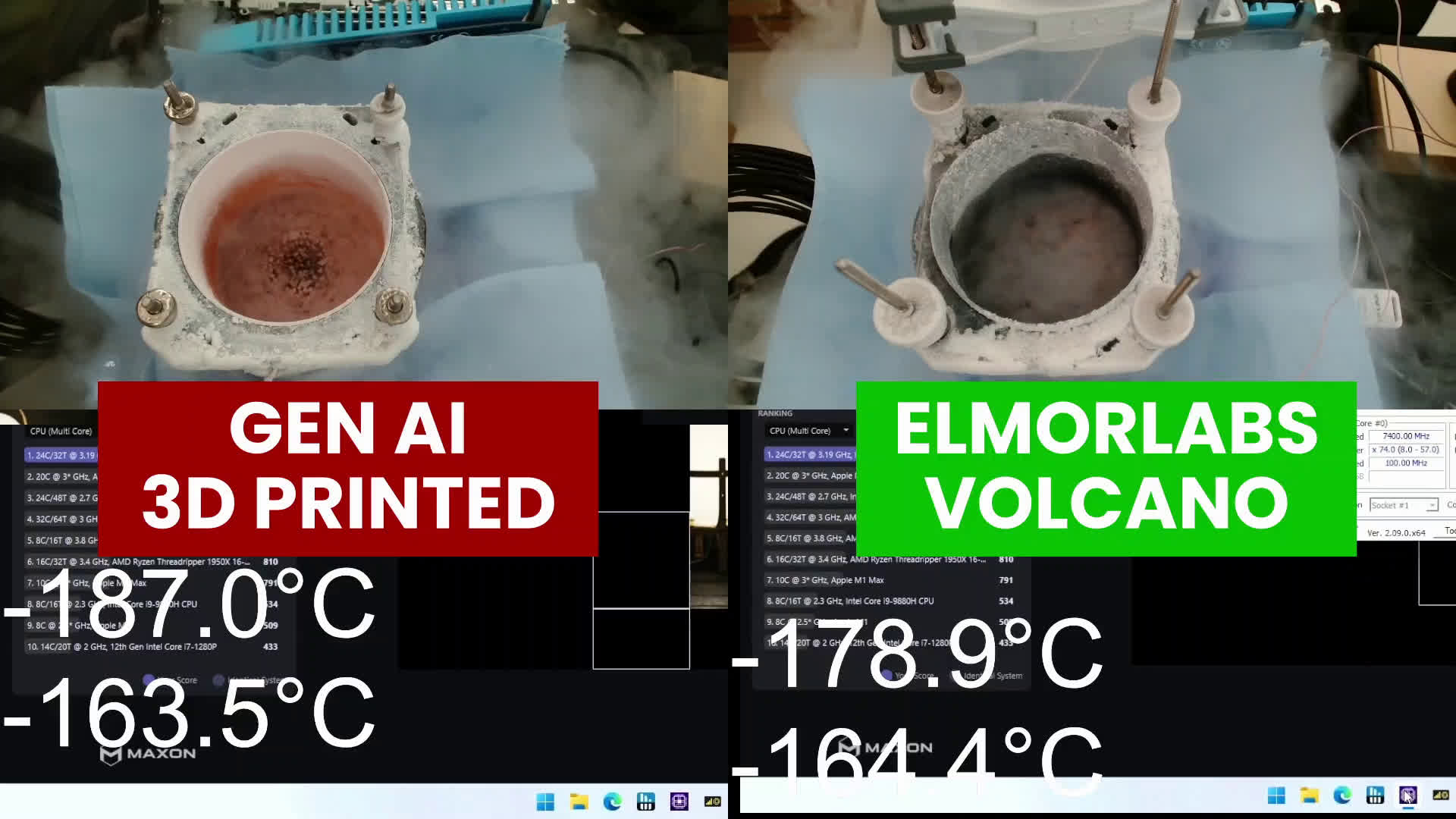

The team took ElmorLabs' existing Volcano LN2 container as a reference point, then tasked Diabatix's ColdStream Next AI to generate an improved design. 3D Systems then brought that digital blueprint to life, 3D printing a prototype using oxygen-free copper powder. Shockingly though, the cutting-edge process commanded a steep $10,000 price tag – a far cry from the $260 cost of the original Volcano.

The AI/3D printed design showed promise in early testing, focusing on three key metrics: cool-down time from room temperature to -194°C, heat-up time from -194°C to 20°C under a 1250W load, and the lowest temperature achieved using 500mL of liquid nitrogen.

It blew past the Volcano in cool-down speed, chilling from 28°C to -194°C in under a minute compared to the Volcano's 3-minute pace. Heat-up performance was better too, with the AI container warming up 30% faster. Efficiency also favored the AI design – using 500mL of LN2, it hit -133°C, while the Volcano stopped short at -100°C.

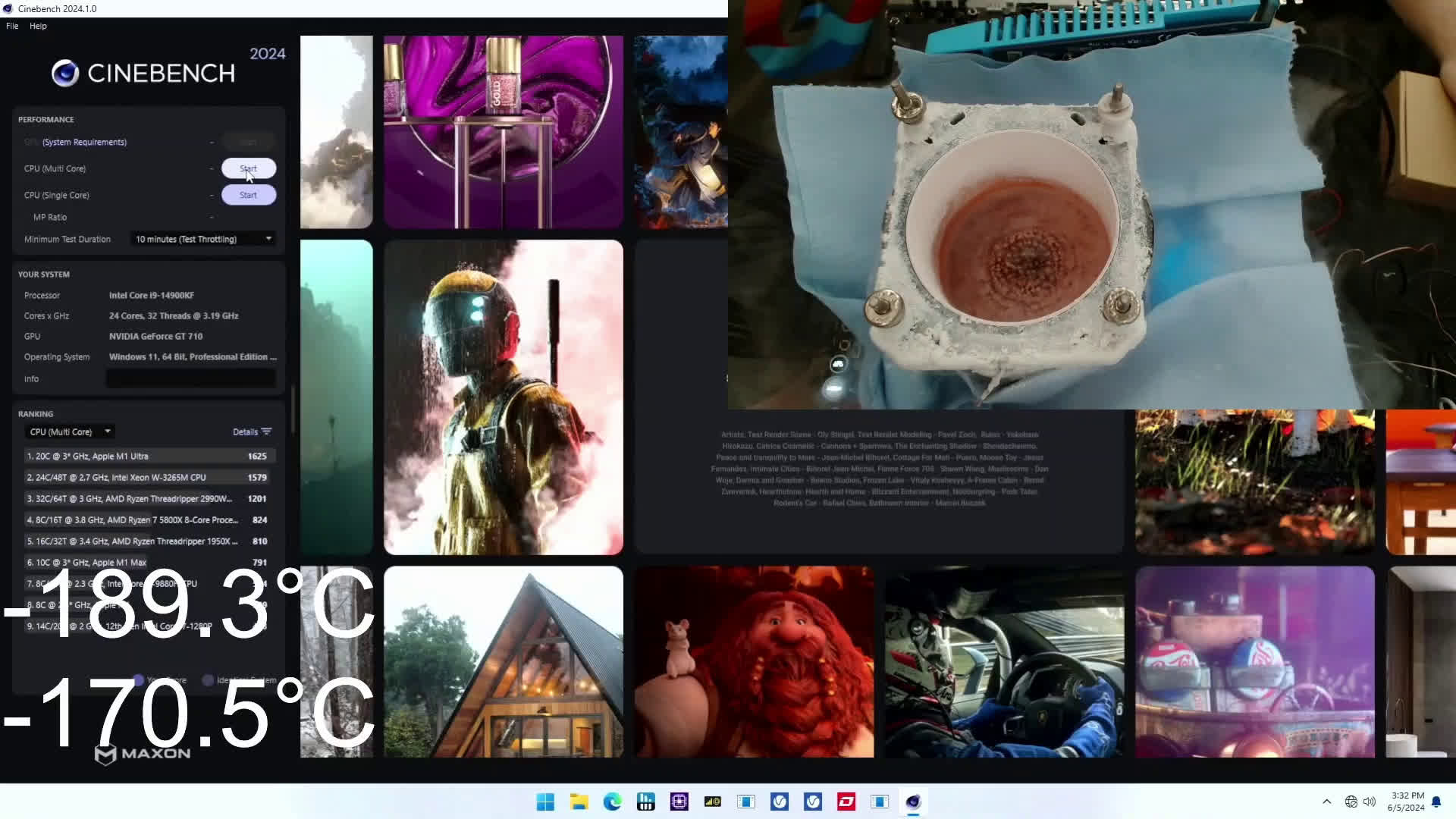

However, since these tests do not represent real-world performance, the team decided to run three more using the Intel Core i9-14900KF Raptor Lake processor. First, they fired up Cinebench 2024 to find the most stable maximum CPU frequency.

"We find that both LN2 containers can handle the Core i9-14900KF with P-cores clocked to 7.4 GHz without any issue. It seemed the AI-generated design could perhaps hold 7.5 GHz just a tad longer. But that might just be run-to-run variation," they noted.

In the second test, they checked the CPU temperature deltas between the heat spreader and cooling container base to assess real heat transfer capabilities. There was also an all-out stress test, pushing over 600W through the chip for several minutes.

While the AI container did pull ahead a smidge, the gains were relatively muted compared to the theoretical test results. Temperature deltas between the CPU heat spreader and container base were tighter on the 3D-printed model, but not by an earth-shattering margin. Even the performance uplift in Cinebench was fairly modest, as seen above.

After crunching the numbers, the team determined that while technically impressive, the AI/3D printed design currently doesn't pencil out from a cost/benefit perspective for modest overclocking scenarios. Not with that $10,000 price tag.

However, they are not done yet. While "nothing concrete" is in hand, the team says they could look into performance and cost optimizations. The design of the LN2 container doesn't necessarily need to be circular, for example. They are also exploring new designs for higher-power CPUs like the Ryzen Threadripper or Intel's Xeon 6.

All in all, the feasibility study may have exposed some limitations, but it also proved generative AI has better uses than simply churning out six-fingered models.

$10,000 cooler designed with AI keeps Core i9-14900KF chilly at 7.5 GHz