Why it matters: In what is another blow to the component industry, Kioxia (formerly Toshiba) and Western Digital report that contamination issues have been found at their joint NAND production factories. Western Digital says that up to 6.5 exabytes of flash memory, or 6.5 million terabytes, have been affected. An amount that will doubtlessly have an impact on the market.

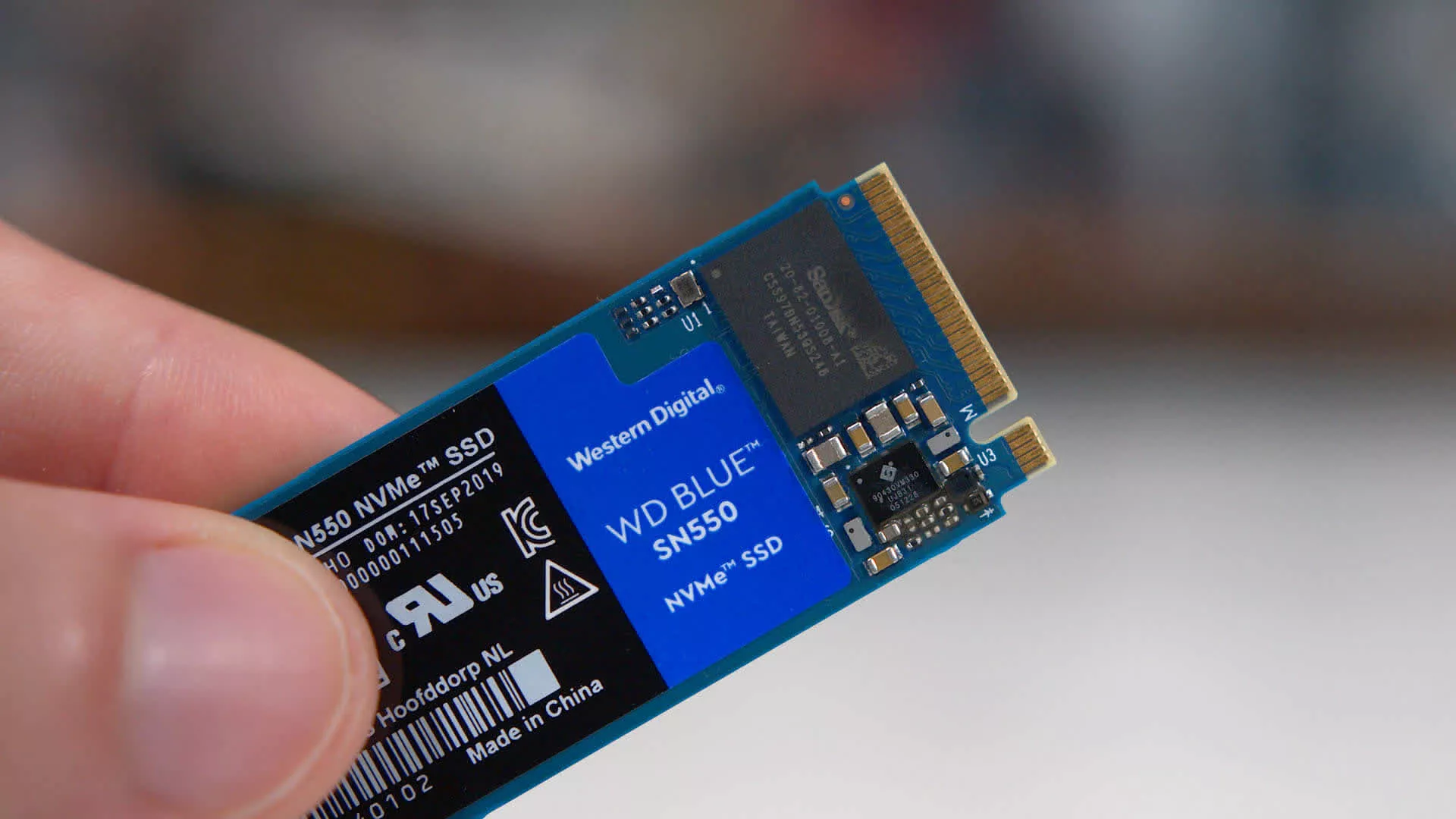

In a statement (via Tom’s Hardware), Kioxia said that operations were halted at its Yokkaichi and Kitakami plants due to a component containing impurities involved in the production of BiCS 3D NAND flash memory, used in a range of SSDs and other products. The company added that it hoped for "early recovery to normal operation."

Western Digital’s statement is the one to reveal that 6.5-exabyte figure. It adds that the company is moving to implement necessary measures that will restore the facilities to normal operational status as quickly as possible.

The stoppage occurred in late January. Given the length of time it takes to manufacture 3D NAND flash chips, the disruption is likely to be felt for months after production restarts, whenever that might be. The likely outcome will be a shortage of NAND-based products and a rise in the price of the companies’ SSDs.

Another unanswered question is whether any of the contaminated NAND has made it out into products that have already shipped, which could lead to recalls being issued.

Although 6.5 exabytes is not a huge chunk of the 207-exabyte total capacity that was shipped in consumer and enterprise SSDs last year, the news comes at a time when the tech industry is already suffering component shortages.

The incident took place just a few weeks after Samsung confirmed it will be adjusting operations at its semiconductor manufacturing facility in Xian after the entire Chinese city was put under lockdown following a surge in Covid-19 cases. Micron, which also has manufacturing facilities in the city, said that staff and contractor reductions have impacted output levels of DRAM assembly and test operations.

https://www.techspot.com/news/93344-kioxia-western-digital-lose-65-exabytes-3d-nand.html