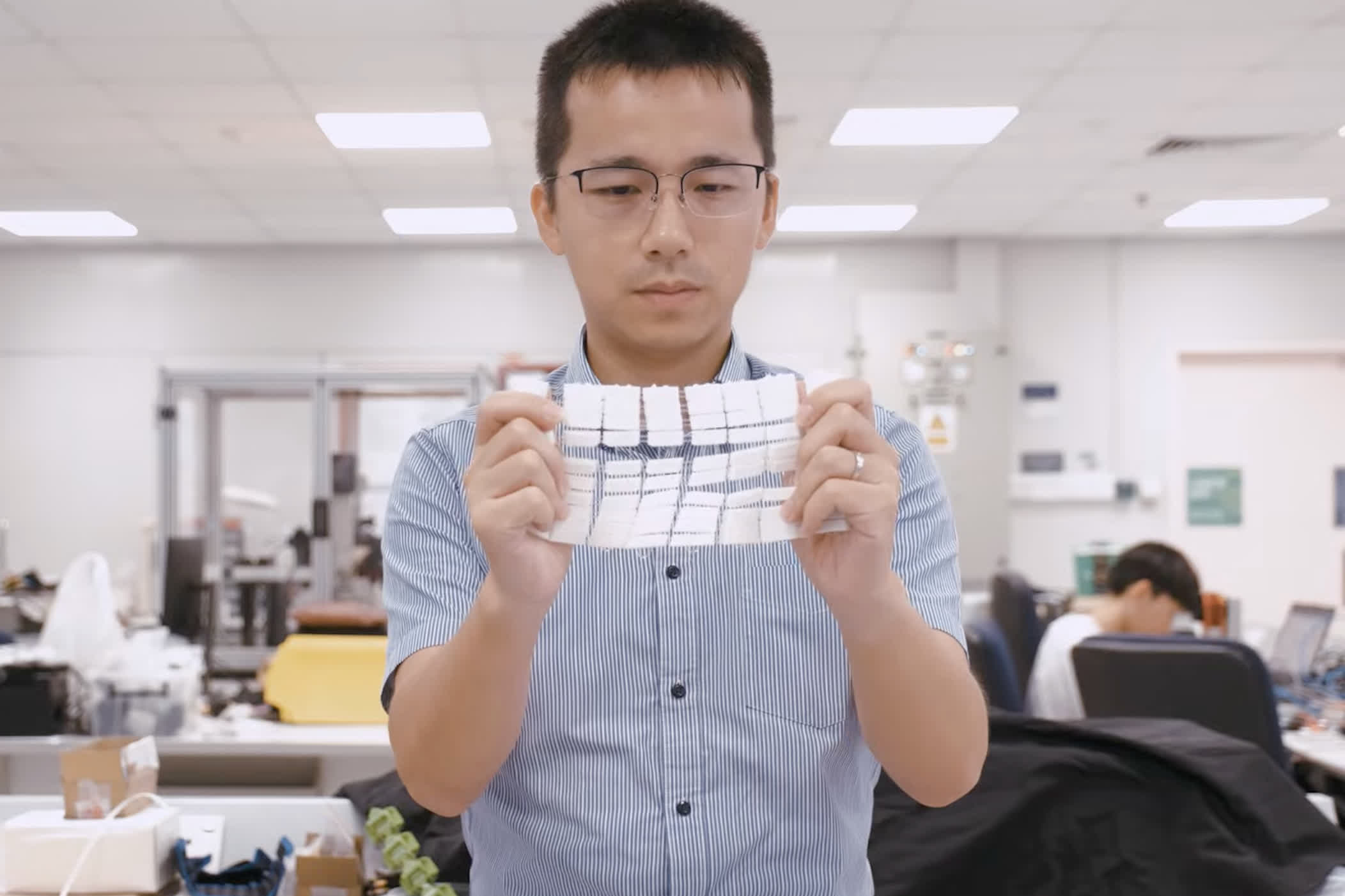

In brief: Scientists have designed a wearable textile that can go from soft to rigid in an instant and could soon be making its way into medical braces, robotic limbs, and much more. The shape-shifting material, called RoboFabric, was cooked up by a team at Singapore's Nanyang Technological University. Taking inspiration from the interlocking scales of pangolins and armadillos, the researchers designed a network of 3D-printed tiles connected by metal fibers running through tiny channels between them.

When the fibers are loose, the tiles can move freely like the links of a chain. But when they contract, the tiles lock together into a sturdy structure that's over 350 times more rigid.

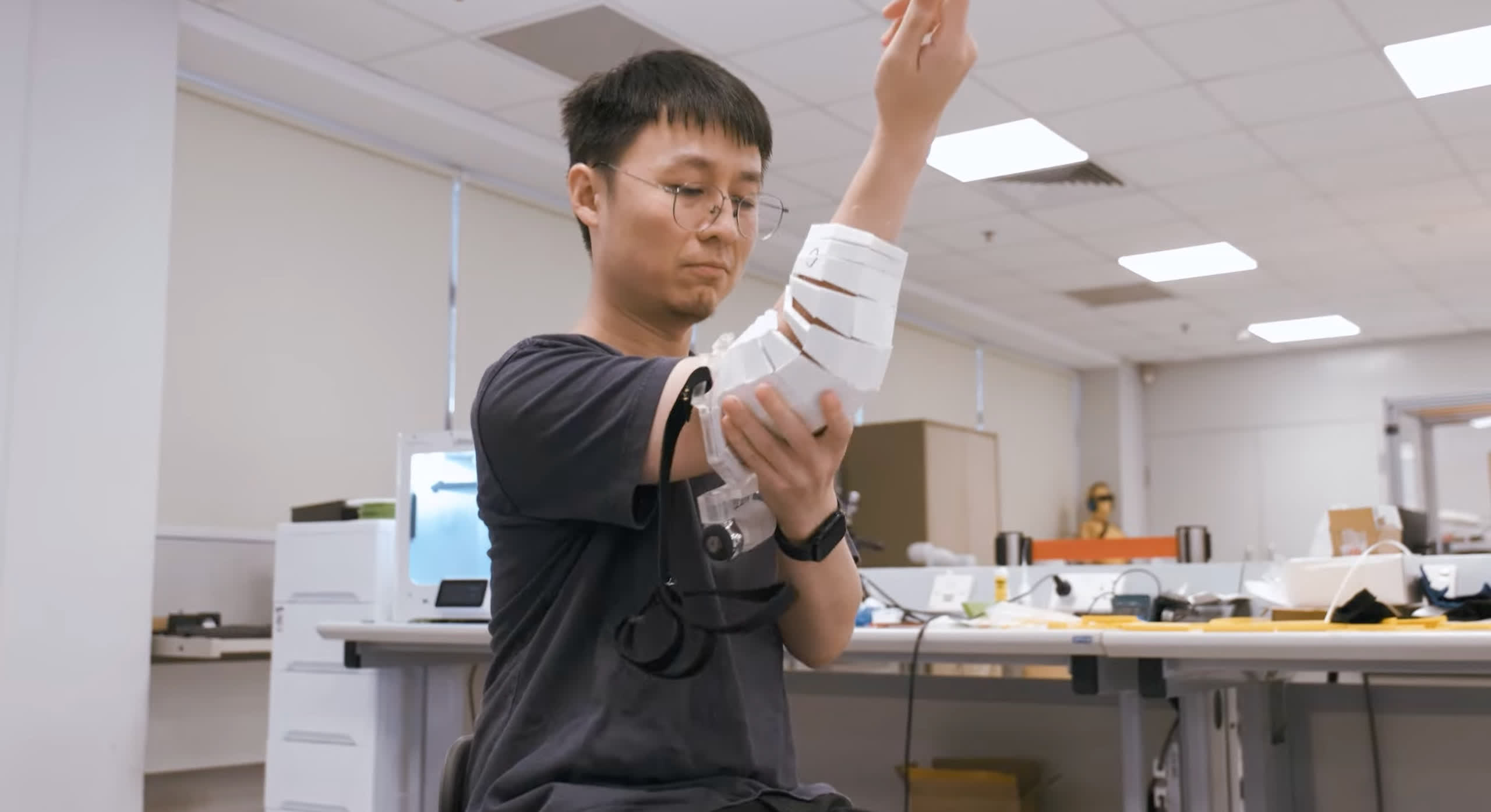

The team found it could reduce the muscle power needed to lift a weight by up to 40%. This could come in particularly useful for individuals with movement disorders like Parkinson's, helping stabilize the movement trajectory so there's less shaking. Imagine an elbow or wrist brace that supports your joints on demand as you're moving heavy objects. The researchers also note that it can be adapted for "knee applications" to improve gait patterns and prevent falls.

"We envision that in future, patients who need a plaster cast for fractures would have the option of customising a flexible limb support that is fabric-like before stiffening," explains lead scientist Yifan Wang. "Unlike conventional rigid and unremovable casts, they would also be easy to put on or remove at the touch of a button. In daily use, joint supports can also help the elderly in their daily tasks, helping to reduce the muscle strength needed for heavier loads."

Making one of these shape-shifting braces starts with a 3D scan of the wearer's arm or leg. Software dissects the 3D model into dozens of geometric tiles that can be 3D printed in about an hour. Metal cables are then threaded through channels between the tiles by hand, although the team does plan to automate the process. Those cables connect to an electronic device to tighten or loosen them as needed.

The medical applications are just the start. In the research paper, Wang's group showed that when RoboFabric is sealed into an elastic skin, it can transition between a flexible state and a stiff state by applying or removing vacuum pressure. They turned it into a small, worm-like 'soft robot' that can crawl, swim, and even form a protective shell on demand.

"These capabilities are important for exploration and rescue robots that need to move in complex terrains and provide protection on demand," the researchers noted.

Perhaps the coolest demo involved equipping a drone with four such robots made from the fabric acting as grippers. When floppy, the grippers fold up into the drone body. When made rigid, they function as grabbing claws that can snatch objects or cushion hard landings. It's an ingenious way to make drones more versatile without sacrificing aerodynamics.

With these prototypes completed, the NTU team is now seeking industry partners to put their miracle fabric through its paces.

Scientists design miracle fabric that turns rigid at the push of a button