Forward-looking: So, you buy a new shirt, wear it a bunch of times until you get sick of it, and then it ends up getting tossed or relegated to the back of your closet. What if instead, you could just dissolve that old shirt into a liquid and use that to make a fresh new one? Researchers at the University of Colorado Boulder have developed a way to do exactly that.

The team from the University of Colorado Boulder's ATLAS Institute has created biodegradable fibers made from gelatin that can be spun into fabric using a compact DIY machine, as detailed in a paper. When you're done wearing the clothes, you simply submerge them in hot water and the fibers dissolve within an hour or less, turning back into a gelatin liquid that can then be re-spun into new threads to make new garments.

Gelatin is common in the bones and hooves of animals like pigs and cows. Meat producers throw this material away in large quantities if it doesn't meet the requirements for consumables like Jell-O, often without realizing its potential for other uses.

The solution could be the answer to the massive textile waste problem. According to stats from the Environmental Protection Agency, over 11 million tons of textiles ended up in US landfills in 2018 alone, making up nearly 8% of total municipal solid waste that year. Being able to dissolve and recycle old clothes could radically reduce that number.

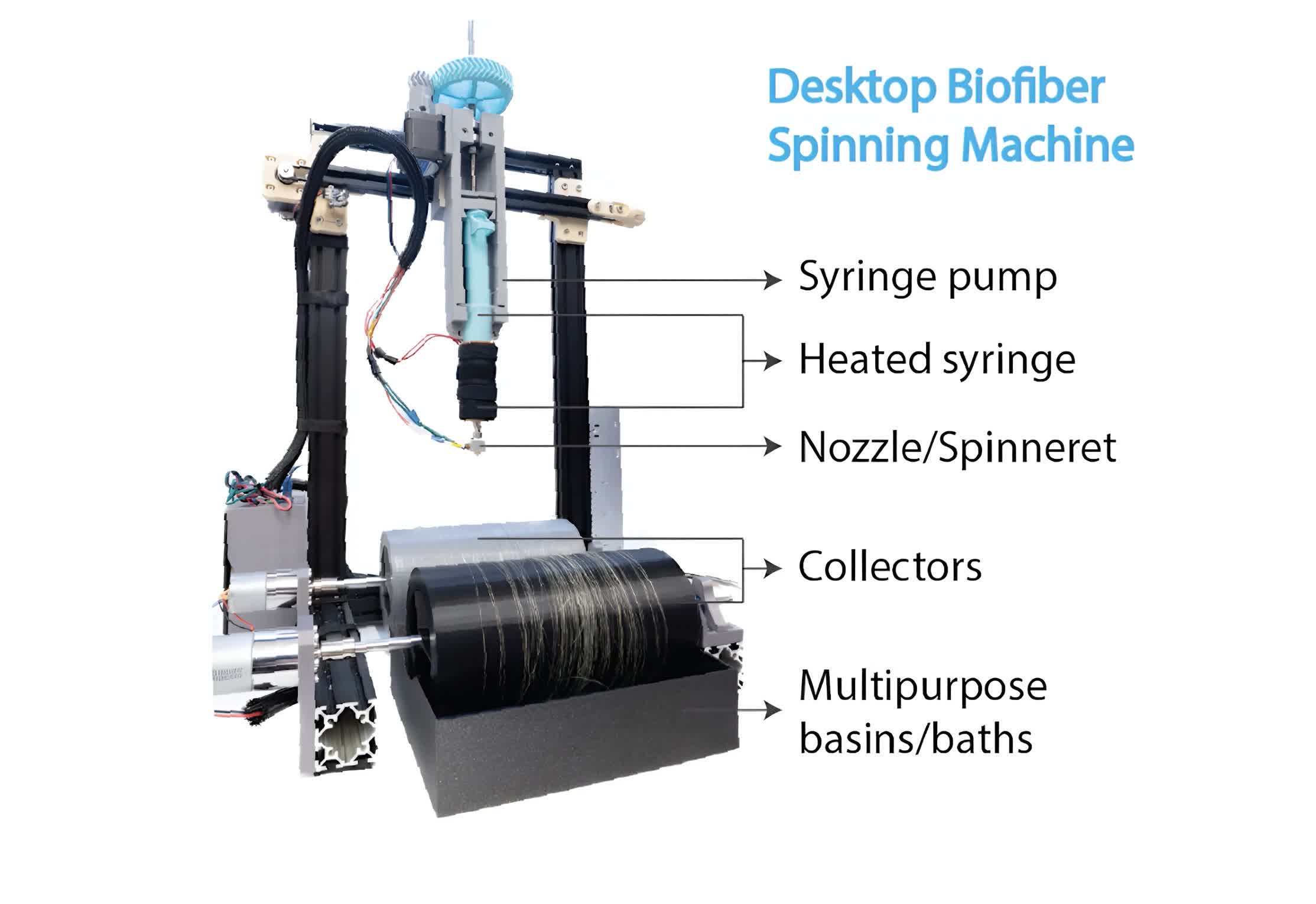

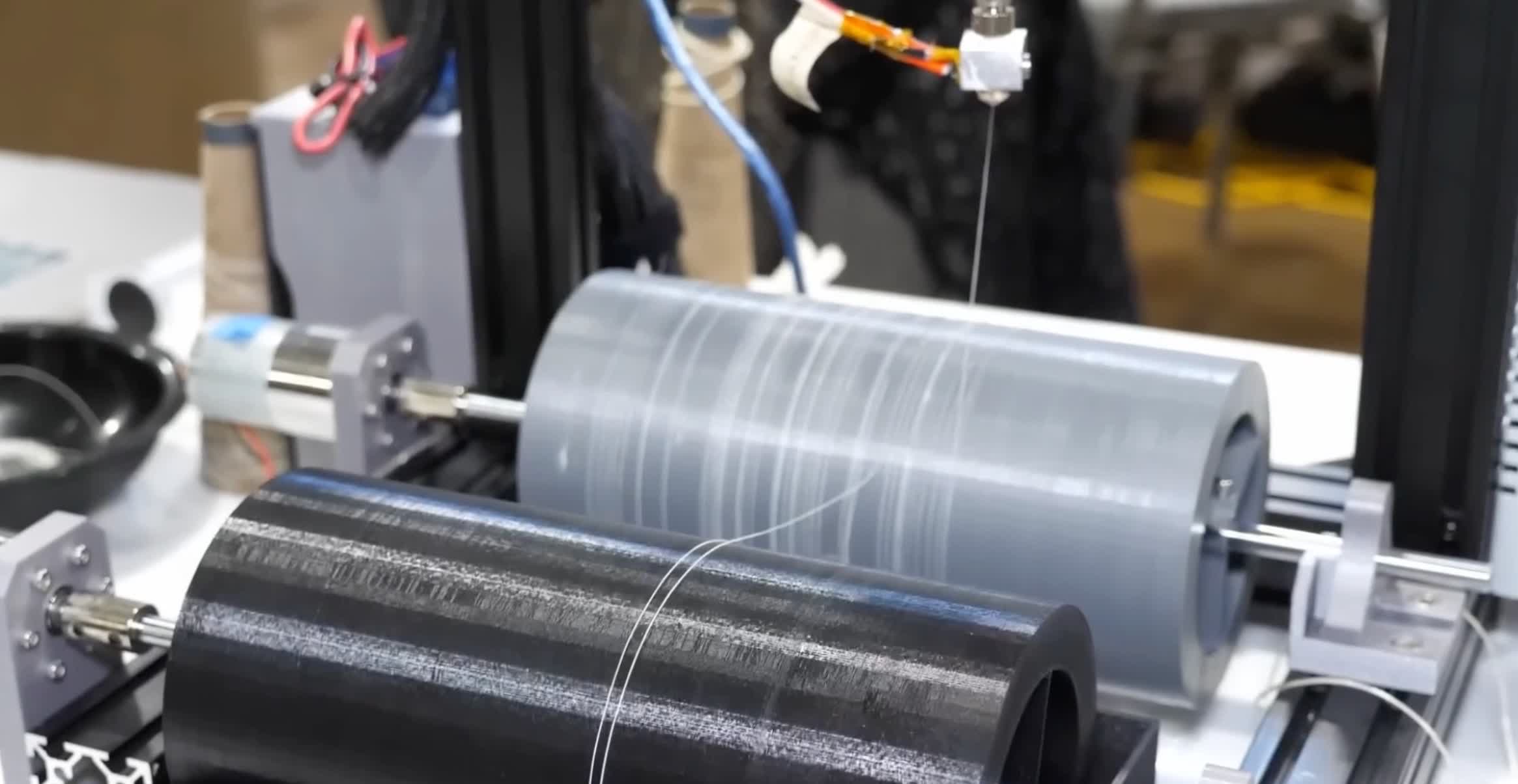

The key innovation here is the gelatin fiber-spinning machine developed by the team, which costs only $560 and features modular parts. It uses a syringe to heat up a gelatin mixture and extrude it through a nozzle, with rollers stretching the liquid into long, thin fibers, much like a spider spinning web. Designers can even add natural dyes, fruit extracts, and other additives to customize properties like elasticity, strength, and color.

The resulting biofibers have a flax-like feel and can be woven into fabrics mimicking common textiles like denim and linen. The fiber chemistry can also be modified for greater resilience so that it doesn't simply dissolve in the rain or washing machine. For instance, the team explored spinning threads from other natural sources like crab shells and algae.

If the garment recycling process becomes as simple as dropping your shirt in a hot bath and re-spinning the liquid, we may finally be able to close the loop on fast fashion's wasteful cycle.

Masthead credit: Parker Burchfield

This machine weaves gelatin-based clothes you can dissolve after use