What just happened? AMD boss Lisa Su has confirmed something that we've been hearing for years now: buying chips from TSMC's US plants will be 5-20% more expensive than purchasing the same silicon from its Taiwan fabs. But Su added that AMD expects its first chips from TSMC's Arizona facilities by the end of the year, and that the extra expense is worth it.

Speaking in an interview with Bloomberg Television after her appearance at an AI event in Washington, Su highlighted the increased price of US-made TSMC chips compared to those from its Taiwan factories.

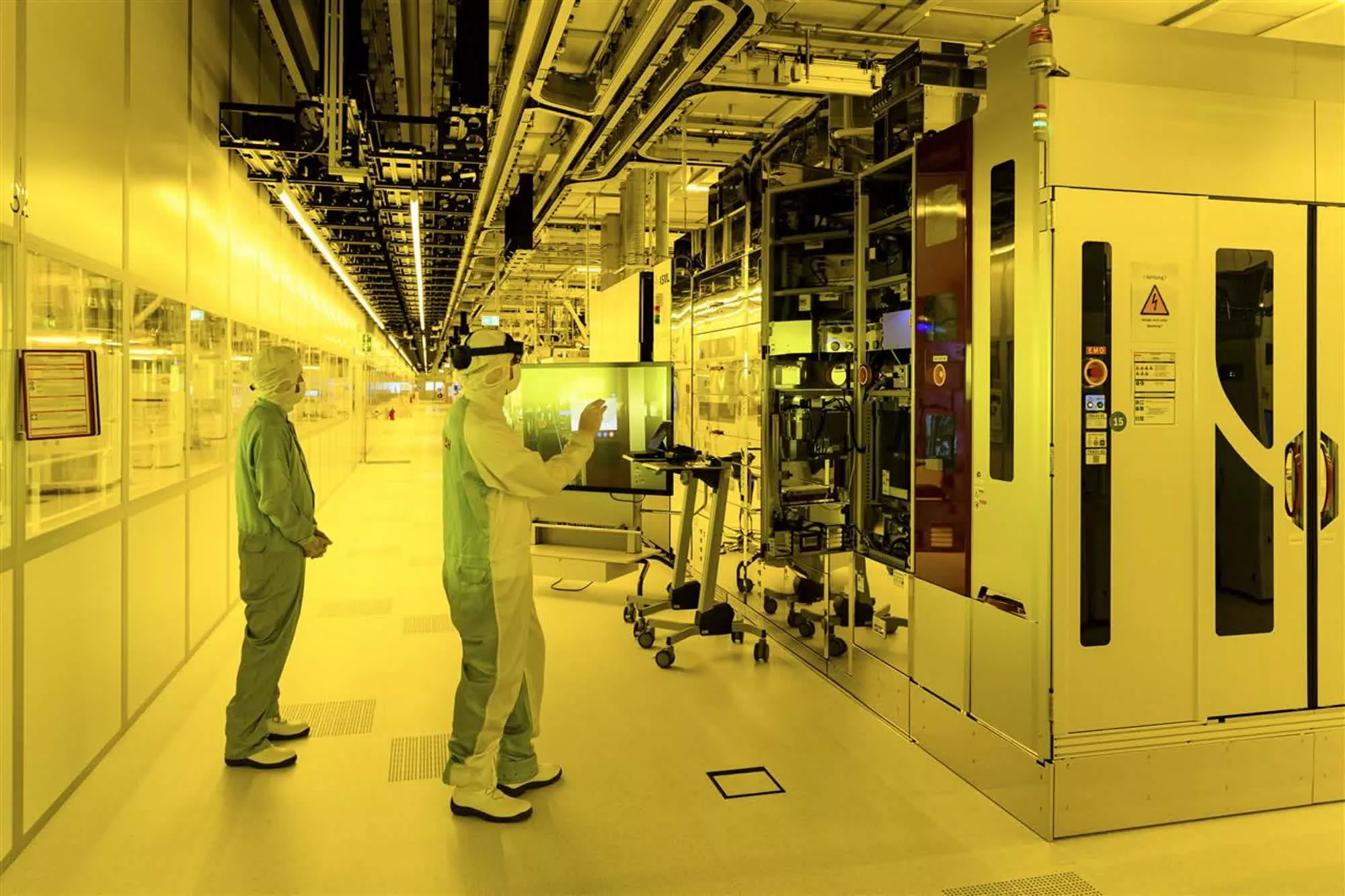

It's no secret that building and running a cutting-edge fab costs more in the US, especially during the initial start-up period. People, concrete, permits, and the whole supporting ecosystem are pricier and less mature than in Taiwan, meaning a higher per-wafer cost.

But Su says that paying the extra money is worth it as it means AMD is diversifying the crucial supply of chips. This will make the semiconductor industry less vulnerable to the type of disruption it experienced during the pandemic-induced chip crisis.

"We have to consider resiliency in the supply chain," she said. "We learned that in the pandemic."

Su also said that the yield rates of TSMC's Arizona plants were already comparable to its fabs in Taiwan.

We heard back in January that TSMC's Arizona fab was already producing AMD Ryzen 9000 chips. The company also confirmed in April that the fifth-generation Epyc Turin chips had been "brought up and validated" in Phoenix, though volume shipments aren't expected until later this year.

Su told Bloomberg that the first customer-shippable lots from Arizona are expected by the end of the year, suggesting the Ryzen 9000 and Epyc Turin chips are the only AMD products being made at TSMC's US facilities right now.

Reports of TSMC charging considerably more for its US-made chips stretch back to 2023 – at that time, the estimate was 30% more.

In April last year, TSMC CEO C. C. Wei said microchips produced outside of Taiwan, including those in the US and Germany, would incur higher manufacturing costs, citing factors such as construction costs, operational expenditures, labor negotiations, and other related factors.

However, an interesting study by Techinsights in March appeared to debunk these claims. While it found that employees cost 200 percent more in the US, modern, fully automated chip manufacturing plants don't need many staff. The bottom line, according to the study, was that TSMC needs to spend just 10% more to process a 300mm chip wafer in Arizona than in Taiwan.

AMD CEO Lisa Su says TSMC chips made in the US cost up to 20% more – but they're worth it