PSA: Asus and other PC hardware vendors have spent the last few years exploring ways to make installing and removing motherboard components easier and safer. Asus' latest method aims to eliminate release buttons and latches from PCIe slots, but recent reports indicate that the procedure risks chipping the gold fingers.

Owners of Asus' AMD X800 and Intel Z800 motherboards should exercise caution when removing their graphics cards. Multiple reports show that the company's recently introduced Q-Release Slim system can scratch the GPU's connection pins.

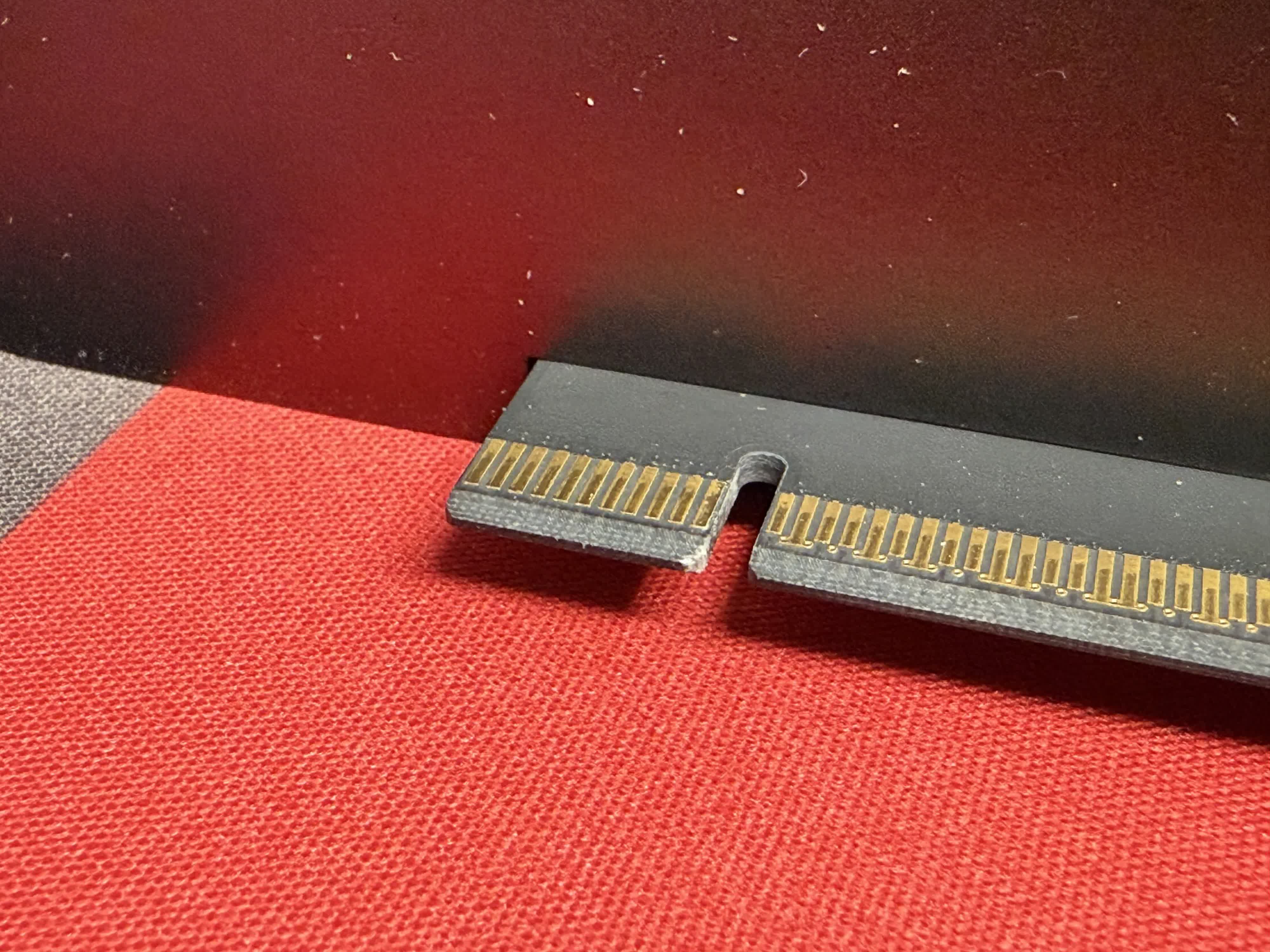

A recently uploaded Bilibili video showed how the mechanism can chip the end of a graphics card's short gold finger, which faces the long gold finger. Hardware Luxx's Andreas Schilling later shared a photo of his GeForce RTX 5090 exhibiting similar damage. Schilling reported that the pins frequently became caught in the PCIe slot during benchmarks involving repeated GPU removal and swapping.

I'm not happy with the solution either. We use the Strix X870E-E Gaming for testing the graphics cards. So I have had to remove graphics cards from the slot a few dozen times. This didn't always go smoothly and very often the card got stuck in the slot. First damage visible. https://t.co/CHVKFBrbY8 pic.twitter.com/1pEUXmQQES

– Andreas Schilling 🇺🇦 🇮🇱 (@aschilling) January 24, 2025

Asus introduced Q-Release Slim to simplify the process of detaching graphics cards and other PCIe add-in boards. Traditional mechanisms require pressing a latch at the end of the slot to release the gold finger, which often proves difficult because large GPUs can completely obscure the latch.

The company began using an alternative method in 2021 involving pressing a release button placed in a more accessible position. MSI demonstrated a similar system at Gamescom last year, suggesting that the trend is catching on. However, Asus's Q-Release Slim mechanism aims to simplify things further.

With Q-Release Slim, users simply hold the motherboard down with one hand, slightly tilt the card upward, and remove it by pulling toward the I/O bracket. The design prevents the gold fingers from shifting in any other direction.

Asus is working to address the recent reports of chipped connectors, but hasn't yet provided details on a remedy. It remains unclear if the company might revert to an earlier system or try something new with future motherboards.

The PCIe slot isn't the only port motherboard manufacturers are trying to improve. MSI also introduced a Q-Release system for the M.2 slot for Z800 boards. Installing and removing NVMe SSDs normally involves screws that can sometimes become frustrating due to their small size. With MSI's new system, pressing a lock button behind the drive secures the SSD without the need for screws. Asus uses a similar system with a release latch and a sliding gate that supports 2280 and 2230 drives. Unlike Asus's GPU slot method, SSD Q-Release mechanisms haven't encountered widespread problems thus far.

Asus Q-Release Slim motherboard mechanism may be damaging graphics card's PCIe connectors