Forward-looking: If GM and LG Energy Solution successfully scale up production and demonstrate the durability of LMR batteries, they could set a new industry standard. Success in these areas would reinforce GM's leadership in the profitable truck and SUV markets while accelerating electric vehicle adoption by addressing two key consumer barriers: cost and range.

General Motors and LG Energy Solution are poised to launch a new era for electric vehicles with the commercial release of lithium manganese-rich (LMR) prismatic battery cells. The companies describe this technology as a significant breakthrough, set to power GM's next generation of electric trucks and full-size SUVs – key segments in GM's dominance of the North American market.

As the race to develop affordable, high-performance EV batteries heats up, automakers explore alternatives to traditional cobalt and nickel chemistries. While companies like Tesla and Ford focus on lithium iron phosphate and other cobalt-free solutions, GM's commitment to LMR technology positions it to challenge established leaders in the premium EV market. The Verge notes that GM could outpace Ford, which won't roll out its LMR technology until 2030.

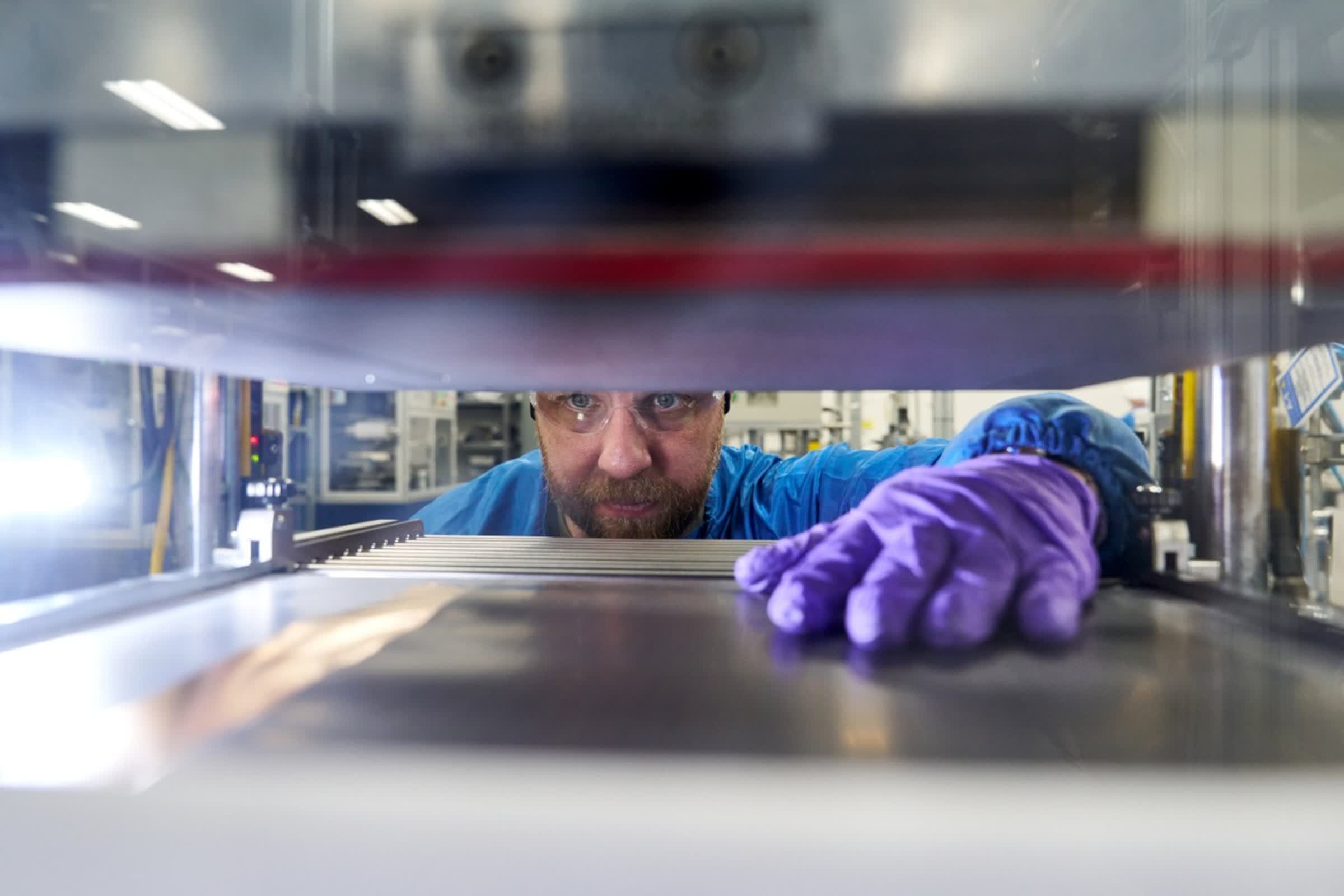

The companies have slated US pre-production of the new battery technology for 2027 at an LG facility under the brand "Ultium Cells," full commercial production in 2028. General Motors will conduct final validation at its new Battery Cell Development Center in Warren, Michigan, and other LG labs. This phase will be crucial in demonstrating the real-world viability of LMR technology, which has historically faced challenges like voltage decay, capacity degradation, and thermal instability.

General Motors engineers have spent nearly a decade addressing these issues – refining cathode materials, optimizing electrolytes, and conducting extensive testing. Their work included prototyping 18 cell variations, representing 1.4 million miles of driving. The result is a battery cell that relies more heavily on manganese – a more abundant and affordable material – while reducing the use of costly and less sustainable cobalt. This shift cuts material costs and allows the new cells to achieve 33 percent higher energy density than top lithium iron phosphate cells while maintaining a similar cost structure.

A key feature of the new batteries is their prismatic design, which replaces the pouch format used in GM's current high-nickel packs. The rectangular shape enables more efficient packaging, especially in larger vehicles like trucks and SUVs. It also reduces the number of required parts, simplifies manufacturing, and reduces costs. With the integration of LMR technology, GM aims to extend the range of its electric trucks, such as the Chevrolet Silverado EV, beyond 400 miles.

The shift to LMR technology aligns with GM's goal of localizing its supply chain. By sourcing manganese and lithium from North America, the company strengthens its ability to withstand potential trade disruptions and better meets growing regulatory and consumer demands for responsible sourcing.

New GM EV battery tech promises extended range and lower production costs by 2028