Editor's take: As Space Forge prepares for its first demonstration mission, the company is positioning itself for a new era in advanced manufacturing. By taking production beyond the confines of Earth, Space Forge hopes to deliver breakthroughs that could reshape industries, strengthen supply chains, and contribute to a more sustainable future.

A British startup focused on manufacturing advanced materials in space has secured $30 million in Series A funding, setting a new record for the country's space technology sector. Called Space Forge, the company plans to use the investment to accelerate the development and launch of satellites designed to produce materials that cannot be made on Earth, with potential applications in semiconductors, quantum computing, and clean energy.

The round was led by the NATO Innovation Fund and supported by a global consortium that includes World Fund, the National Security Strategic Investment Fund, and the British Business Bank's Regional Angels Programme.

Space Forge's ambitious plan centers on developing satellites capable of manufacturing materials in orbit. According to the company, the microgravity, vacuum, and extreme temperature variations in space create conditions that are impossible to replicate on Earth.

These conditions allow for the creation of high-performance materials that could dramatically enhance the efficiency and capabilities of semiconductors, quantum computing hardware, clean energy systems, and defense technologies.

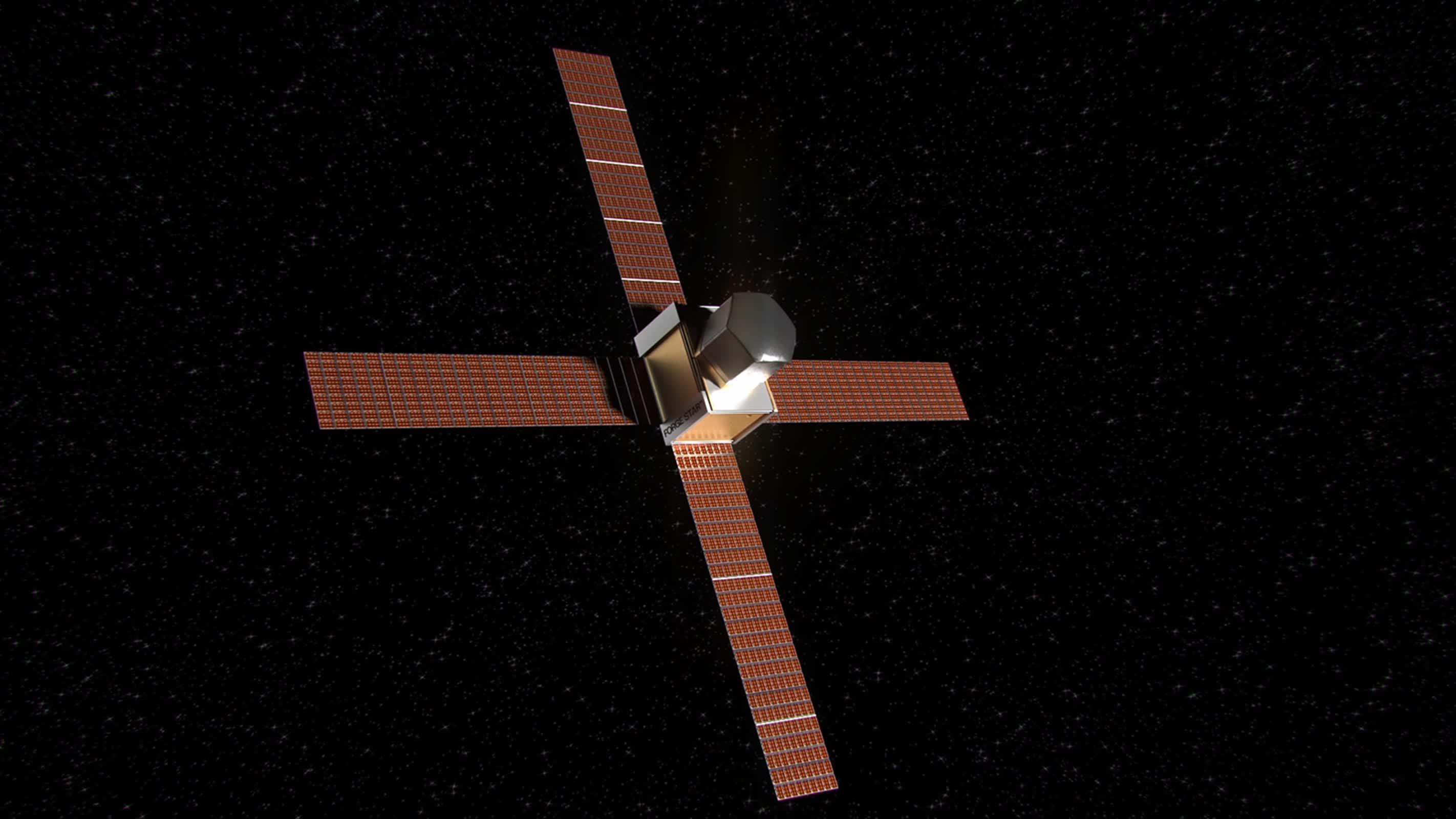

The newly acquired funds will accelerate work on Space Forge's next-generation satellite, ForgeStar-2, and support the launch of its first manufacturing satellite, ForgeStar-1.

The latter is scheduled for an in-orbit demonstration mission in 2025 and is designed to be returnable and reusable, setting the stage for scalable and sustainable space-based manufacturing.

The potential impact of these technologies extends beyond performance improvements. Space Forge claims that materials produced in space could reduce carbon dioxide emissions by up to 75 percent and cut energy usage by 60 percent in critical infrastructure sectors such as data centers.

With ForgeStar®-1 officially licensed for launch, we are one step closer to unlocking next-generation materials.

– Space Forge (@Space_Forge) March 24, 2025

🎥 Hear from Josh Western, Co-Founder & CEO, on what this milestone means for the future.

🔗 https://t.co/zUQi9LT0uC#SpaceForge #ForgeStar1 #ISAM #UKSpace @UK_CAA... pic.twitter.com/3gSC3mozQZ

However, Space Forge faces several challenges as it moves forward. The technical complexity of manufacturing in orbit and returning products safely to Earth remains significant. The company must also navigate regulatory hurdles and demonstrate that its process can be scaled cost-effectively. The upcoming demonstration mission will be a crucial test for both the technology and the business case behind space-based manufacturing.

Investors and industry observers see Space Forge's approach as a timely response to global supply chain vulnerabilities. Daria Saharova, General Partner at World Fund, pointed to Europe's heavy reliance on imported semiconductors, noting that 90 percent of the world's most advanced chips are produced in Taiwan. She warned that any geopolitical disruption in the region could have severe consequences for Europe's technology sector. "We urgently need a resilient, homegrown supply of the next-gen supermaterials required for the future of compute," she said.

Space Forge raises $30 million to develop satellites for space-based manufacturing