Why it matters: Prices of computer components and other consumer electronics have recently either risen or stagnated. Manufacturers blame component costs, inflation, supply chain shocks, and other macroeconomic conditions. Reports indicate TSMC's latest node process won't alleviate the problem.

According to DigiTimes, TSMC intends to sell its 3nm N3 semiconductors for $20,000 per wafer. Contract prices for larger companies like Apple, Intel, or Nvidia will likely be lower, but these increased costs will probably filter down to consumers regardless.

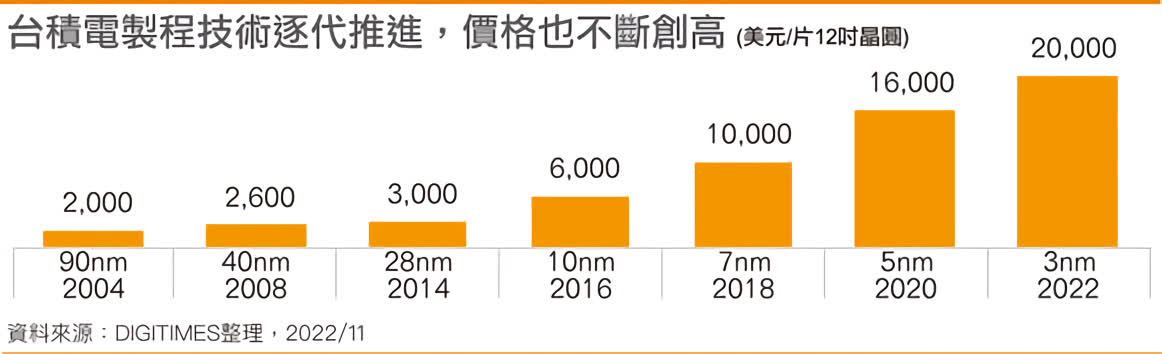

DigiTimes has charted the history of wafer prices, starting with TSMC's 90nm process in 2004, which cost a tenth of the N3 wafers at $2,000. Estimates indicate N3 wafer costs will rise 25 percent over TSMC's 5nm N5 process, which was around $16,000 per wafer. DigiTimes didn't specify whether it accounted for inflation.

The 3nm node is seeing a price hike primarily because the tools to make it are still expensive. The scanners TSMC uses for extreme ultraviolet (EUV) lithography cost around $150 million each, and fabs require multiple scanners. The N5 process requires 14 lithography layers, while N3 needs even more.

Samsung's yield problems with its 4nm and 3nm processes also leave TSMC uncontested in the bleeding-edge semiconductor space. Qualcomm initially partnered with Samsung for its new chips but had to rely on TSMC for its Snapdragon 8 Gen 2 mobile platform.

While semiconductors are far from the only element affecting component and electronics prices, they will influence the price tags consumer see. After revealing the shockingly expensive RTX 4000 series graphics cards in September, Nvidia boss Jensen Huang declared (again) that Moore's Law is dead. The Jury is still out on that claim, but TSMC's price hike may lend it some extra strength.

Apple could be the biggest TSMC customer affected by the price increase. The upcoming iPhone 15's A17 Bionic chip will use the Taiwanese company's 3nm process, and Apple has begrudgingly accepted TSMC's price hike. Last year, Apple accounted for a quarter of the company's sales.

Costlier semiconductors could also affect game console pricing. Sony increased the price of the PlayStation 5 in August, blaming supply chain problems, inflation, and manufacturing costs. Microsoft also admitted that it would eventually have to raise the price of its Xbox Series consoles, likely next year.

https://www.techspot.com/news/96742-tsmc-reportedly-plans-raise-3nm-wafer-prices-25.html