Purchasing luxury goods and high end electronics online can often bring into question the authenticity of such products. IBM is aiming to eliminate the gray areas of supply chains with an optical tool used to inspect items at the microscopic level.

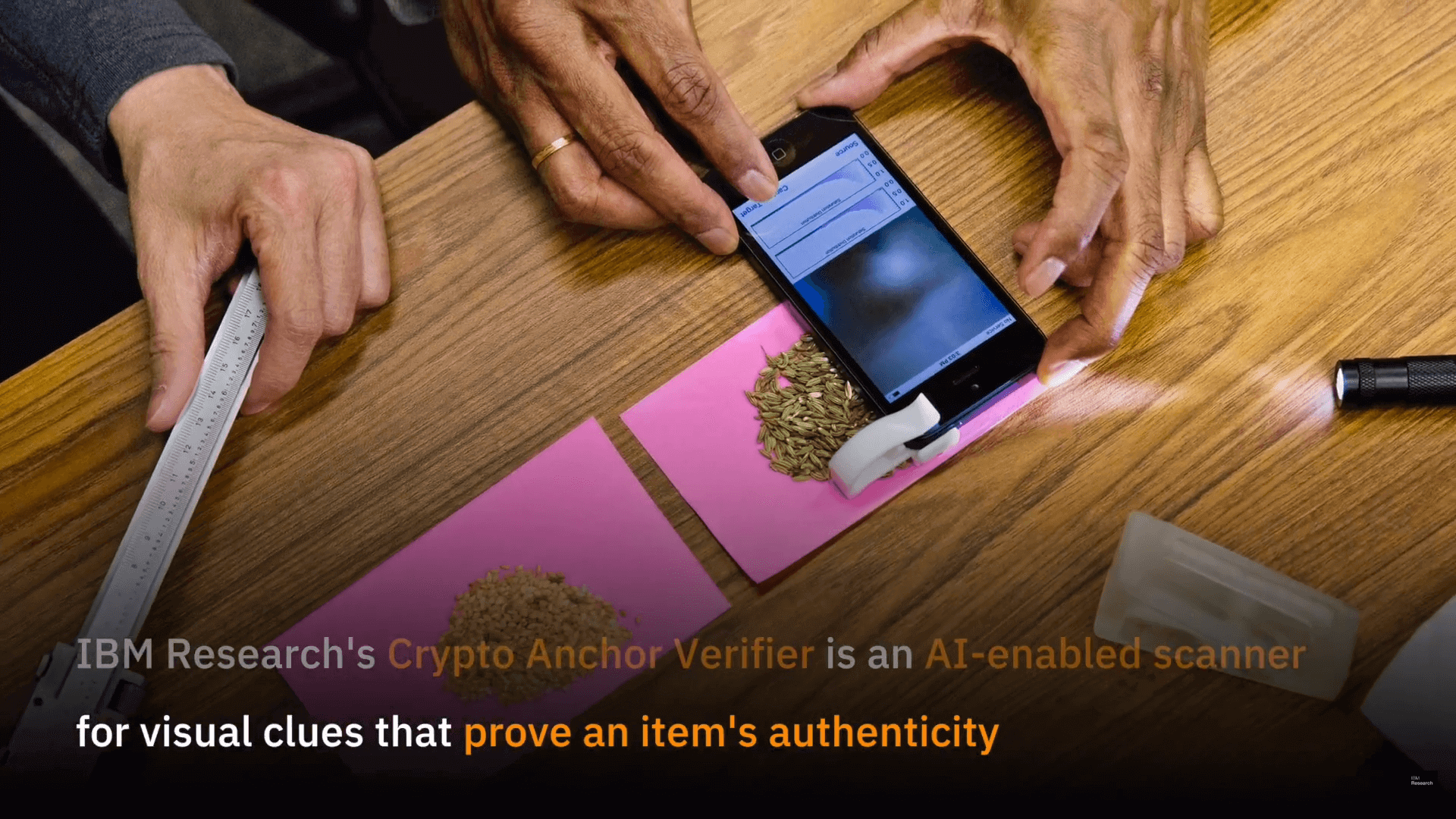

In short, a small external sensor is placed over a smartphone camera. The sensor is pressed against a product for testing of validity. A combination of spectroscopy, imaging, and artificial intelligence algorithms produce a result to determine whether a certain good is authentic.

When examining objects at micron levels, patterns and textures invisible to the human eye regularly stick out like a sore thumb. Two products produced with only slight differences in material will have drastically different small scale appearances. This technology could be applied to paper currency, pharmaceuticals, jewelry, or just about any other solid or liquid substance.

IBM's first application of its verification tool is in the diamond industry. Taking measurements of a diamond at different angles will allow for its authenticity to be checked at different points throughout a supply chain, ensuring that the same piece has not been tampered with or switched out with a fake.

All tracking data is stored in blockchain format. Once products are rolling off of a production line, validation data can be stored permanently such that it cannot be altered. At designated checkpoints, comparisons can be made to the original data, leaving record of a pass or fail at each test so that the entire product history is traceable.