Editor's take: Scientists have devised a new way to make super-strong glass. The process mixes regular oxide glass with aluminosilicate at extremely high temperatures and pressure. The resulting material has some publications calling it the "strongest glass ever," but is it?

Material scientists at the University of Bayreuth in Germany have developed a glass that is more than twice as strong as Gorilla Glass. Corning's Gorilla Glass Victus is its toughest material, with a fracture toughness of 0.76 megapascals (MPa). The glass produced in the Bayreuth study – published in this month's Nature Materials journal – has a strength of 1.99 MPa. The researchers claim it surpasses "any other reported bulk oxide glasses," prompting Extreme Tech to post the sensationalizing headline, "Scientists Use Extreme Heat and Pressure to Create Strongest Glass Ever." But is it the strongest glass ever?

The headline got me thinking about a time in 2016 when people went nuts about Star Trek predicting the discovery of transparent aluminum. You might recall the scene in Star Trek 4: The Voyage Home, where Scotty and Bones convince a polymer engineer to provide them with materials to build a tank to house a whale in trade for the formula for transparent aluminum (below).

It was a sensationalized story at the time, quickly debunked by people pointing out that aluminum oxynitride (AlON) development patents go back as far as 1978, eight years before the movie came out. Some of the first commercial samples were created in 1984, two years before the film was released. Of course, years of research progress ensued, and a 2016 breakthrough in the manufacturing process discovered by Oxford University led to the widely reported misconception.

The University of Bayreuth's material is subtly different from AlON, but it's not stronger. AlON is manufactured by fusing aluminum, oxygen, and nitrogen atoms into a transparent ceramic. Aluminosilicate glass mixes standard oxide glass with silicon, aluminum, boron, and oxygen (aluminosilicate). Chemically, the main difference is the substitution of boron for nitrogen.

The AlON manufacturing process involves mixing alumina powder with carbon black and heating it to around 1,650-1,850 degrees Celsius in a nitrogen-rich atmosphere. Bayreuth researchers combined oxide glass with aluminosilicate and heated it to 1,000C under 10-15 gigapascals (GPa) of pressure. Both processes create a paracrystalline structure that is very hard (below).

The Bayreuth process results in glass with a fracture strength of 1.99 MPa +/- 0.06 MPa, only slightly higher or lower than AlON (2.0 MPa). So, for all intents and purposes, this new glass is the same strength as current forms of AlON. Unfortunately, it doesn't even tie for first when it comes to strength.

Earlier this year, Chinese scientists synthesized a glass hard enough to scratch diamonds. Tentatively named AM-III, the amorphous material was rated at 113 GPa under the Vickers hardness test. For reference, many natural diamonds have a strength between 70-100 GPa. However, the hardest stones can tilt the scale to 150 GPa. This glass is made by very slowly heating and compressing fullerene to 25 GPa of pressure and 1,200C over 12 hours.

All these substances differ to varying degrees, but they are all labeled as "glass." I don't believe Extreme Tech was being disingenuous in its headline. I think it just got caught up in the hype, as we have seen in past advancements in this field. The study's claim that aluminosilicate glass is stronger than any other bulk oxide glass is valid, but only with the qualification "bulk oxide." Both AlON and fullerene glass can rightfully make the same claim with the latter being the current strongest.

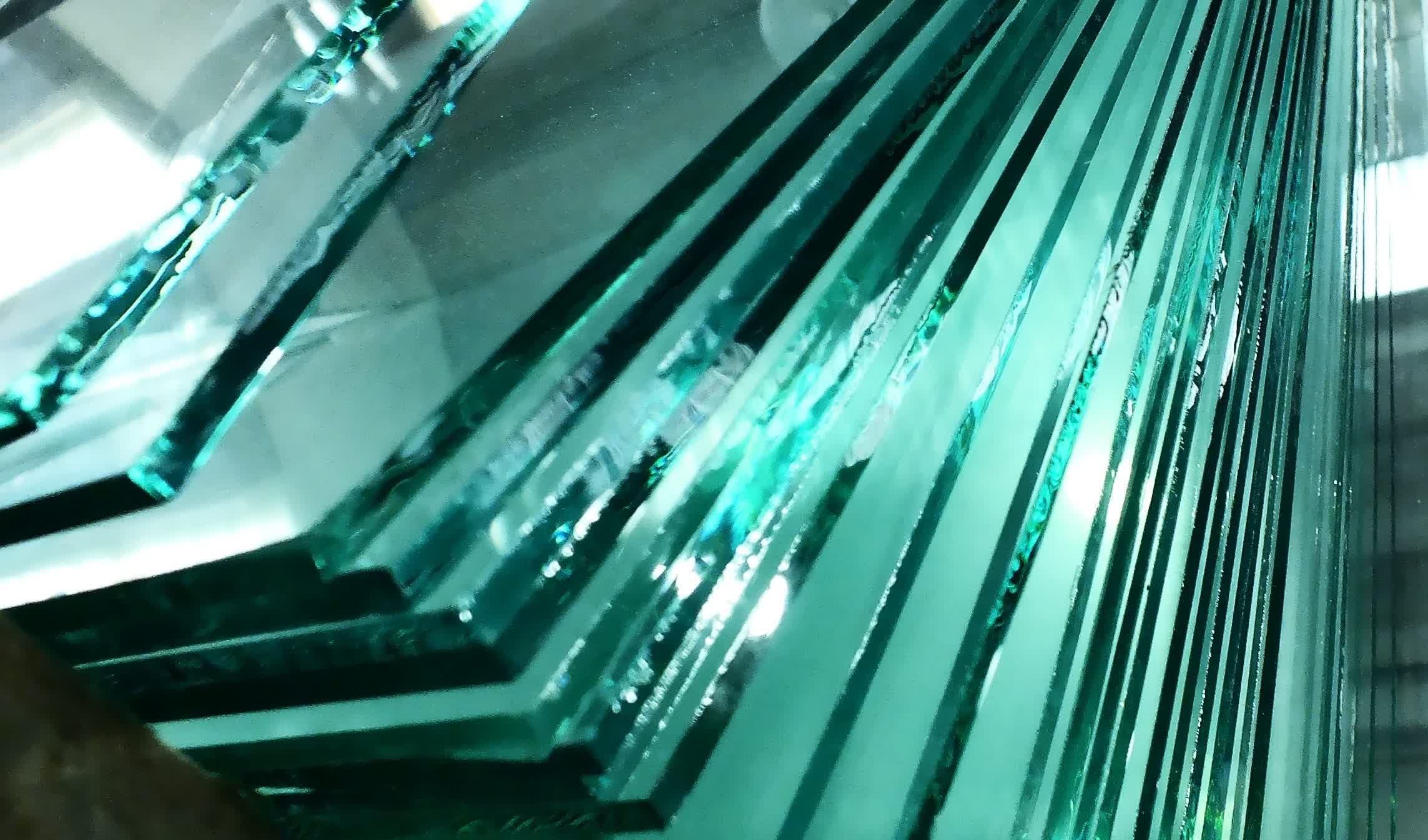

Image credit: Stilvetro Acqui