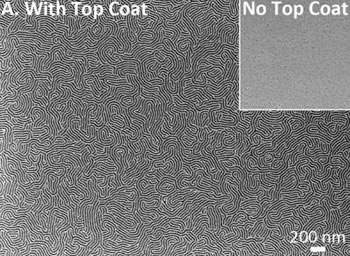

Comparison of the block copolymers self-assembling with and without the new top coat

University of Texas researchers have announced a new technique that could produce a fivefold increase in hard drive capacity. Led by C. Grant Willson, professor of chemistry, biochemistry and engineering at UT, the team has discovered a way to use self-organizing substances called block copolymers to help isolate a disk's magnetic dots, thereby allowing them to be closer together without becoming unstable.

The researchers explain that today's drives write ones and zeroes as magnetic dots across a metal disk. Naturally, the closer those dots are, the more data can be held in the same area. However, with current production methods, those dots can't get much denser than about a terabit of information per square inch without having their magnetic fields interfere with each other, causing them to randomly flip states.

Enter the block copolymers: "At room temperature, coated on a disk surface, they don't look like much. But if they're designed in the right way, and given the right prod, they'll self-assemble into highly regular patterns of dots or lines. If the surface onto which they're coated already has some guideposts etched into it, the dots or lines will form into precisely the patterns needed for a hard disk drive," UT's post reads.

Although the directed self-assembly of such materials isn't entirely new, the UT researchers have made several advances. The team has synthesized block copolymers that self-assemble into the smallest dots in the world, and that happens in about 30 seconds, which is also a record. "I'm not even sure how it is possible to do it that fast. It doesn't seem reasonable, but once in a while you get lucky," Willson said.

(Left to right) Engineering Professor Chris Ellison, undergraduate Leon Dean

and Chemistry Professor C. Grant Willson, co-authors of a paper on the technology

published in the peer-reviewed magazine Science (photo via Alex Wang/UT)

The announcement didn't reveal when the technology might trickle down to consumer electronics, but it has the attention of several industry heavyweights. The UT team has been collaborating with HGST (formerly a unit of Hitachi, now a subsidiary of Western Digital), who is working to determine if the technology can be used in its products. Other collaborators include Nissan Chemical Company and Molecular Imprints.

"The patterns of super small dots can now self-assemble in vertical or perpendicular patterns at smaller dimensions than ever before," Thomas Albrecht, manager of patterned media technology at HGST said. "That makes them easier to etch into the surface of a master plate for nanoimprinting, which is exactly what we need to make patterned media for higher capacity disk drives."