Engineers at Macronix, one of the world's largest flash memory makers, have reportedly developed a new technology that can extend the life of NAND cells by more than a thousand times by simply applying heat.

Most of today's flash modules fail after cells have been programmed and erased about 10,000 times – or even less, in the case of many budget-minded storage products such as the 3,000 p/e Kingston HyperX 3K.

Although that type of longevity is sufficient for consumer devices that are replaced regularly anyway, it's hardly ideal for enterprise situations where solid-state drives may see heavy usage around the clock for many years.

While companies have used various software schemes such as wear-leveling to help improve the rate of a flash cell's deterioration, Macronix's engineers have produced a compelling hardware-based solution.

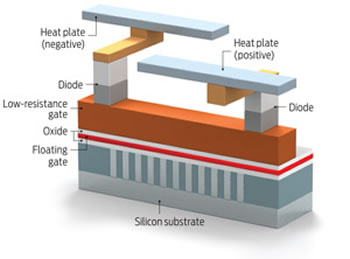

When a cell dies, it's generally due to the degradation of oxide layers around its floating gate (see the image below). Years ago, engineers found that they could restore this oxide layer by applying heat – specifically, by baking flash chips in an oven at 250C (482F). Obviously, this wouldn't be practical for end users, so researchers had to create some form of internal mechanism, and that's just what Macronix has done.

The company has produced chips with integrated heat plates that "heal" worn cells by zapping them at 800C (1,472F) for a few milliseconds. With that occasional jolt of heat, researchers say that flash cells can handle more than 100 million write/erase cycles – and by more than 100 million, they haven't seen any signs of death at that point, noting that a billion cycles could be possible, but it'll take several months to test.

In addition to boosting the longevity of flash cells, the heat also enables faster erasing, which Macronix believes may bring "thermally assisted" drives that tout better performance. It's worth noting that although the heat results in greater power consumption, it shouldn't reduce battery life because it can be configured to run when a device is plugged in. There's no word on when the technology may hit consumer electronics.