The personal computing business as we know it owes itself to an environment of enthusiasts, entrepreneurs and happenstance. Before PCs, the mainframe and minicomputer business model was formed around a single company providing an entire ecosystem; from building the hardware, installation, maintenance, writing the software, and training operators.

This approach would serve its purpose in a world that seemingly required few computers. It made the systems hugely expensive yet highly lucrative for the companies involved since the initial cost and service contract ensured a steady stream of revenue. The "big iron" companies weren't the initial driving force in personal computing because of cost, lack of off-the-shelf software, perceived lack of need for individuals to own computers, and the generous profit margins afforded from mainframe and minicomputer contracts.

It was in this atmosphere that personal computing began with hobbyists looking for creative outlets not offered by their day jobs involving the monolithic systems. The invention of the microprocessor, DRAM, and EPROM integrated circuits would spark the widespread use of the BASIC high-level language variants, which would lead to the introduction of the GUI and bring computing to the mainstream. The resulting standardization and commoditization of hardware would finally make computing relatively affordable for the individual.

Over the next few weeks we'll be taking an extensive look at the history of the microprocessor and the personal computer, from the invention of the transistor to modern day chips powering a multitude of connected devices.

1947 - 1974: Foundations

Leading up to Intel's 4004, the first commercial microprocessor

Early personal computing required enthusiasts to have skills in both electrical component assembly (predominantly the ability to solder) and machine coding, since software at this time was a bespoke affair where it was available at all.

The established commercial market leaders didn't take personal computing seriously because of limited input-output functionality and software, a dearth of standardization, high user skill requirement, and few envisaged applications. Intel's own engineers had lobbied for the company to pursue a personal computing strategy almost as soon as the 8080 started being implemented in a much wider range of products than originally foreseen. Steve Wozniak would plead with his employer, Hewlett-Packard, to do the same.

John Bardeen, William Shockley and Walter Brattain at Bell Labs, 1948.

While hobbyists initiated the personal computing phenomenon, the current situation is largely an extension of the lineage that began with work by Michael Faraday, Julius Lilienfeld, Boris Davydov, Russell Ohl, Karl Lark-Horovitz, to William Shockley, Walter Brattain, John Bardeen, Robert Gibney, and Gerald Pearson, who co-developed the first transistor (a conjugation of transfer resistance) at Bell Telephone Labs in December 1947.

Bell Labs would continue to be a prime mover in transistor advances (notably the Metal Oxide Semiconductor transistor, or MOSFET in 1959) but granted extensive licensing in 1952 to other companies to avoid anti-trust sanctions from the U.S. Department of Justice. Thus Bell and its manufacturing parent, Western Electric, were joined by forty companies including General Electric, RCA, and Texas Instruments in the rapidly expanding semiconductor business. Shockley would leave Bell Labs and start Shockley Semi-Conductor in 1956.

The first transistor ever assembled, invented by Bell Labs in 1947

An excellent engineer, Shockley's caustic personality allied with his poor management of employees doomed the undertaking in short order. Within a year of assembling his research team he had alienated enough members to cause the mass exodus of "The Traitorous Eight", which included Robert Noyce and Gordon Moore, two of Intel's future founders, Jean Hoerni, inventor of the planar manufacturing process for transistors, and Jay Last. Members of The Eight would provide the nucleus of the new Fairchild Semiconductor division of Fairchild Camera and Instrument, a company that became the model for the Silicon Valley start-up.

Fairchild company management would go on to increasingly marginalize the new division because of focus on profit from high profile transistor contracts such as those used in the IBM-built flight systems of the North American XB-70 Valkyrie strategic bomber, the Autonetics flight computer of the Minuteman ICBM system, CDC 6600 supercomputer, and NASA's Apollo Guidance Computer.

While hobbyists initiated the personal computing phenomenon, the current situation is largely an extension of the lineage that began with work on early semiconductors in the late 1940s.

However, profit declined as Texas Instruments, National Semiconductor, and Motorola gained their share of contracts. By late 1967, Fairchild Semiconductor had become a shadow of its former self as budget cuts and key personnel departures began to take hold. Prodigious R&D acumen wasn't translating into commercial product, and combative factions within management proved counter-productive to the company.

The Traitorous Eight who quit Shockley to start Fairchild Semiconductor. From left: Gordon Moore, Sheldon Roberts, Eugene Kleiner, Robert Noyce, Victor Grinich, Julius Blank, Jean Hoerni, Jay Last. (Photo © Wayne Miller/Magnum)

Chief among those to leave would be Charles Sporck, who revitalized National Semiconductor, as well as Gordon Moore and Robert Noyce. While over fifty new companies would trace their origins from the breakup of Fairchild's workforce, none achieved so much as the new Intel Corporation in such a short span. A single phone call from Noyce to Arthur Rock, the venture capitalist, resulted in the $2.3 million start-up funding being raised in an afternoon.

The ease with which Intel was brought into existence was in large part due to the stature of Robert Noyce and Gordon Moore. Noyce is largely credited with the co-invention of the integrated circuit along with Texas Instrument's Jack Kilby, although he almost certainly borrowed very heavily from earlier work carried out by James Nall and Jay Lathrop's team at the U.S. Army's Diamond Ordnance Fuze Laboratory (DOFL), which produced the first transistor constructed using photolithography and evaporated aluminum interconnects in 1957-59, as well as Jay Last's integrated circuit team (including the newly acquired James Nall) at Fairchild, of which Robert Noyce was project chief.

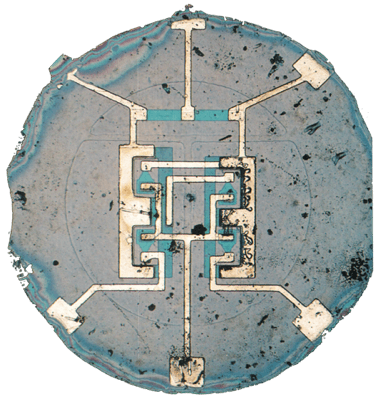

First planar IC (Photo © Fairchild Semiconductor).

Moore and Noyce would take with them from Fairchild the new self-aligned silicon gate MOS (metal oxide semiconductor) technology suitable for manufacturing integrated circuit that had recently been pioneered by Federico Faggin, a loanee from a joint venture between the Italian SGS and Fairchild companies. Building upon the work of John Sarace's Bell Labs team, Faggin would take his expertise to Intel upon becoming a permanent U.S. resident.

Fairchild would rightly feel aggrieved over the defection, as it would over many employee breakthroughs that ended up in the hands of others – notably National Semiconductor. This brain drain was not quite as one sided as it would appear, since Fairchild's first microprocessor, the F8, in all likelihood traced its origins to Olimpia Werke's unrealized C3PF processor project.

In an era when patents had yet to assume the strategic importance they have today, time to market was of paramount importance and Fairchild was often too slow in realizing the significance of its developments. The R&D division became less product-orientated, devoting sizable resources to research projects.

Texas Instruments, the second largest integrated circuit producer, quickly eroded Fairchild's position as market leader. Fairchild still held a prominent standing in the industry, but internally, the management structure was chaotic. Production quality assurance (QA) was poor by industry standards with yields of 20% being common.

Over fifty new companies would trace their origins from the breakup of Fairchild's workforce; none achieved so much as the new Intel Corp in such a short span.

While engineering employee turnover increased as "Fairchildren" left for more stable environments, Fairchild's Jerry Sanders moved from aerospace and defense marketing to overall director of marketing and unilaterally decided to launch a new product every week – the "Fifty-Two" plan. The accelerated time to market would doom many of these products to yields of around 1%. An estimated 90% of the products shipped later than scheduled, carried defects in design specification, or both. Fairchild's star was about to be eclipsed.

If Gordon Moore and Robert Noyce's stature gave Intel a flying start as a company, the third man to join the team would become both the public face of the company and its driving force. Andrew Grove, born András Gróf in Hungary in 1936, became Intel's Director of Operations despite having little background in manufacturing. The choice seemed perplexing on the surface – even allowing for his friendship with Gordon Moore – as Grove was an R&D scientist with a background in chemistry at Fairchild and a lecturer at Berkeley with no experience in company management.

The fourth man in the company would define its early marketing strategy. Bob Graham was technically the third employee of Intel, but was required to give three months' notice to his employer. The delay in moving to Intel would allow Andy Grove to acquire a much larger management role than originally envisaged.

Intel's first hundred employees pose outside the company's Mountain View, California, headquarters, in 1969.

(Source: Intel / Associated Press)

An excellent salesman, Graham was seen as one of two outstanding candidates for the Intel management team – the other, W. Jerry Sanders III, was a personal friend of Robert Noyce. Sanders was one of the few Fairchild management executives to retain their jobs in the wake of C. Lester Hogan's appointment as CEO (from an irate Motorola).

Sanders' initial confidence at remaining Fairchild's top marketing man evaporated quickly as Hogan grew unimpressed with Sanders' flamboyancy and his team's unwillingness to accept small contracts ($1 million or less). Hogan effectively demoted Sanders twice in a matter of weeks with the successive promotions of Joseph Van Poppelen and Douglas J. O'Conner above him. The demotions achieved what Hogan had intended – Jerry Sanders resigned and most of Fairchild's key positions were occupied by Hogan's former Motorola executives.

Within weeks Jerry Sanders had been approached by four other ex-Fairchild employees from the analog division interested in starting up their own business. As originally conceived by the four, the company would produce analog circuits since the breakup (or meltdown) of Fairchild was fostering a vast number of start-ups looking to cash in on the digital circuit craze. Sanders joined on the understanding that the new company would also pursue digital circuits. The team would have eight members, including Sanders, Ed Turney, one of Fairchild's best salesmen, John Carey, and chip designer Sven Simonssen as well as the original four analog division members, Jack Gifford, Frank Botte, Jim Giles, and Larry Stenger.

Advanced Micro Devices, as the company would be known, got off to a rocky start. Intel had secured funding in less than a day based on the company being formed by engineers, but investors were much more reticent when faced with a semiconductor business proposal headed by marketing executives. The first stop in securing AMD's initial $1.75 million capital was Arthur Rock who had supplied funding for both Fairchild Semiconductor and Intel. Rock declined to invest, as would a succession of possible money sources.

Eventually, Tom Skornia, AMD's newly minted legal representative arrived at Robert Noyce's door. Intel's co-founder would thus become one of the founding investors in AMD. Noyce's name on the investor list added a degree of legitimacy to the business vision that AMD had so far lacked in the eyes of possible investors. Further funding followed, with the revised $1.55 million target reached just before the close of business on June 20, 1969.

AMD got off to a rocky start. But Intel's Robert Noyce becoming one of the company's founding investors added a degree of legitimacy to its business vision in the eyes of possible investors.

Intel's formation was somewhat more straightforward allowing the company to get straight to business once funding and premises were secured. Its first commercial product was also one of the five notable industry "firsts" accomplished in less than three years that were to revolutionize both the semiconductor industry and the face of computing.

Honeywell, one of the computer vendors that lived within IBM's vast shadow, approached numerous chip companies with a request for a 64-bit static RAM chip.

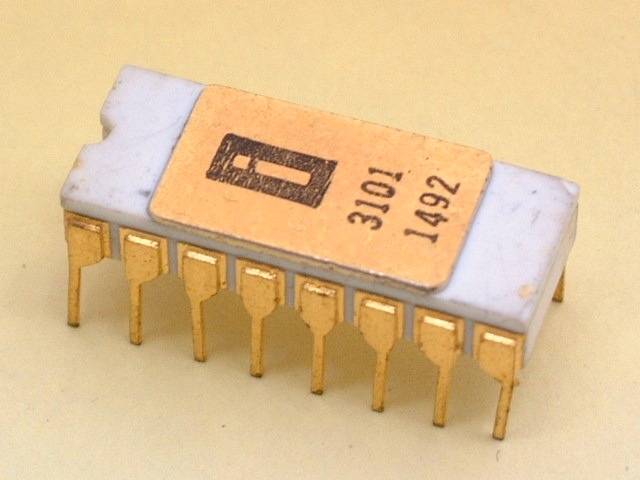

Intel had already formed two groups for chip manufacture, a MOS transistor team led by Les Vadász, and a bipolar transistor team led by Dick Bohn. The bipolar team was first to achieve the goal, and the world's first 64-bit SRAM chip was handed over to Honeywell in April 1969 by its chief designer, H.T. Chua. Being able to produce a successful first up design for a million dollar contract would only add to Intel's early industry reputation.

Intel's first product, a 64-bit SRAM based on the newly developed Schottky Bipolar technology. (CPU-Zone)

In keeping with the naming conventions of the day, the SRAM chip was marketed under its part number, 3101. Intel, along with virtually all chipmakers of the time did not market their products to consumers, but to engineers within companies. Part numbers, especially if they had significance such as the transistor count, were deemed to appeal more to their prospective clients. Likewise, giving the product an actual name could signify that the name masked engineering deficiencies or a lack of substance. Intel tended to only move away from numerical part naming when it became painfully apparent that numbers couldn't be copyrighted.

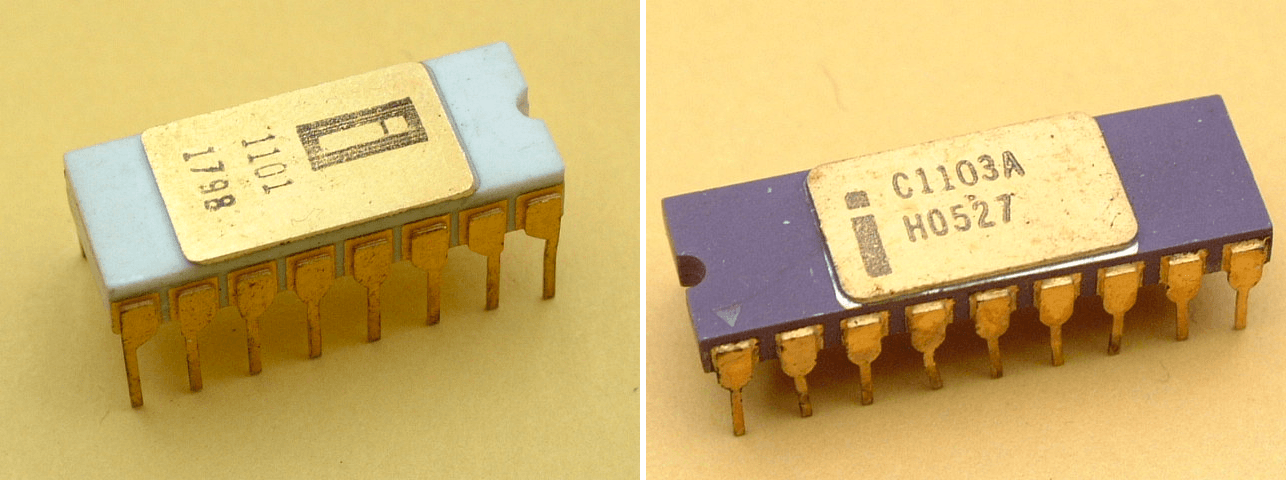

While the bipolar team provided the first breakout product for Intel, the MOS team identified the main culprit in its own chips failings. The silicon-gate MOS process required numerous heating and cooling cycles during chip manufacturing. These cycles caused variations in the expansion and contraction rate between the silicon and the metal oxide, which led to cracks that broke circuits in the chip. Gordon Moore's solution was to "dope" the metal oxide with impurities to lower its melting point allowing the oxide to flow with the cyclic heating. The resulting chip that arrived in July 1969 from the MOS team (and an extension of the work done at Fairchild on the 3708 chip) became the first commercial MOS memory chip, the 256-bit 1101.

Honeywell quickly signed up for a successor to the 3101, dubbed the 1102, but early in its development a parallel project, the 1103, headed by Vadász with Bob Abbott, John Reed and Joel Karp (who also oversaw the 1102's development) showed considerable potential. Both were based on a three-transistor memory cell proposed by Honeywell's William Regitz that promised much higher cell density and lower manufacturing cost. The downside was that the memory wouldn't retain information in an unpowered state and the circuits would need to have voltage applied (refreshed) every two milliseconds.

The first MOS memory chip, Intel 1101, and first DRAM memory chip, Intel 1103. (CPU-Zone)

At the time, computer random access memory was the province of magnetic-core memory chips. This technology was rendered all but obsolete with the arrival of Intel's 1103 DRAM (dynamic random access memory) chip in October 1970, and by the time manufacturing bugs were worked out early next year, Intel had a sizeable lead in a dominant and fast growing market – a lead it benefited from until Japanese memory makers caused a sharp decline in memory prices at the start of the 1980's due to massive infusions of capital into manufacturing capacity.

Intel launched a nationwide marketing campaign inviting magnetic-core memory users to phone Intel collect and have their expenditure on system memory slashed by switching to DRAM. Inevitably, customers would enquire about second source supply of the chips in an era where yields and supply couldn't be taken for granted.

Andy Grove was vehemently opposed to second sourcing, but such was Intel's status as a young company that had to accede to industry demand. Intel chose a Canadian company, Microsystems International Limited as its first second source of chip supply rather than a larger, more experienced company that could dominate Intel with its own product. Intel would gain around $1 million from the license agreement and would gain further when MIL attempted to boost profits by increasing wafer sizes (from two inches to three) and shrinking the chip. MIL's customers turned to Intel as the Canadian firm's chips came off the assembly line defective.

Intel launched a nationwide marketing campaign inviting magnetic-core memory users to phone Intel collect and have their expenditure on system memory slashed by switching to DRAM.

Intel's initial experience wasn't indicative of the industry as a whole, nor its own later issues with second sourcing. AMD's growth was directly aided by becoming a second source for Fairchild's 9300 series TTL (Transistor-Transistor Logic) chips and securing, designing, and delivering a custom chip for Westinghouse's military division that Texas Instruments (the initial contractor) had difficulty producing on time.

Intel's early fabrication failings using the silicon gate process also led to the third and most immediately profitable chip as well as an industry lead in yields. Intel assigned another ex-Fairchild alumnus, the young physicist Dov Frohmann, to investigate the process issues. What Frohmann surmised was that the gates of some of the transistors had become disconnected, floating above and encased within the oxide separating them from their electrodes.

Frohmann also demonstrated to Gordon Moore that these floating gates could hold an electrical charge because of the surrounding insulator (in some cases many decades), and could thus be programmed. In addition, the floating gate electrical charge could be dissipated with ionizing ultra violet radiation which would erase the programming.

Conventional memory required the programming circuits to be laid down during the chip's manufacturer with fuses built into the design for variations in programming. This method is costly on a small scale, needs many different chips to suit individual purposes and requires chip alteration when redesigning or revising the circuits.

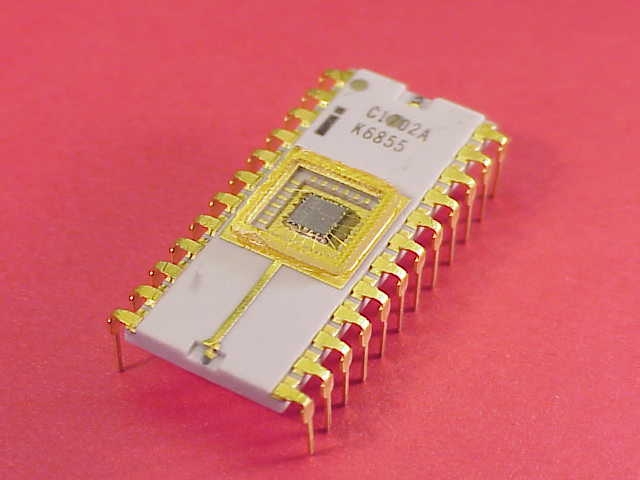

The EPROM (Erasable, Programmable Read-Only Memory) revolutionized the technology, making memory programming much more accessible and many times faster since the client did not have to wait for their application specific chips to be manufactured.

The downside of this technology was that in order for the UV light to erase the chip, a relatively expensive quartz window was incorporated in the chip packaging directly above the ROM chip to allow light access. The high cost would later be eased by the introduction of one-time programmable (OTP) EPROMs that did away with the quartz window (and erase function), and electrically erasable, programmable ROMs (EEPROM).

As with the 3101, initial yields were very poor – less than 1% for the most part. The 1702 EPROM required a precise voltage for memory writes. Variances in manufacturing translated into an inconsistent write voltage requirement – too little voltage and the programming would be incomplete, too much risked destroying the chip. Joe Friedrich, recently lured away from Philco, and another who had honed their craft at Fairchild, hit upon passing a high negative voltage across the chips before writing data. Friedrich named the process "walking out" and it would increase yields from one chip every two wafers to sixty per wafer.

Intel 1702, the first EPROM chip. (computermuseum.li)

Because the walk out did not physically alter the chip, other manufacturers selling Intel-designed ICs would not immediately discover the reason for Intel's leap in yields. These increased yields directly impacted Intel's fortunes as revenue climbed 600% between 1971 and 1973. The yields, stellar in comparison to the second source companies conferred a marked advantage for Intel over the same parts being sold by AMD, National Semiconductor, Sigtronics, and MIL.

ROM and DRAM were two essential components of a system that would become a milestone in the development of personal computing. In 1969, the Nippon Calculating Machine Corporation (NCM) approached Intel desiring a twelve-chip system for a new desktop calculator. Intel at this stage was in the process of developing its SRAM, DRAM, and EPROM chips and was eager to obtain its initial business contracts.

NCM's original proposal outlined a system requiring eight chips specific to the calculator but Intel's Ted Hoff hit upon the idea of borrowing from the larger minicomputers of the day. Rather than individual chips handling individual tasks, the idea was to make a chip that tackled combined workloads, turning the individual tasks into sub-routines as the larger computers did – a general-purpose chip. Hoff's idea would reduce the number of chips needed to just four – a shift register for input-output, a ROM chip, a RAM chip, and the new processor chip.

NCM and Intel signed the contract for the new system on February 6, 1970, and Intel received an advance of $60,000 against a minimum order of 60,000 kits (with eight chips per kit minimum) over three years. The job to bring the processor and its three support chips to fruition would be entrusted to another disaffected Fairchild employee.

Federico Faggin grew disillusioned with both Fairchild's inability to translate its R&D breakthroughs into tangible products before being exploited by rivals and his own continued position as a manufacturing process engineer, while his main interest lay first in chip architecture. Contacting Les Vadász at Intel, he was invited to head a design project with no more foreknowledge than its description as "challenging". Faggin was to find out what the 4-chip MCS-4 project entailed on April 3, 1970, his first day of work, when he was briefed by engineer Stan Mazor. The next day Faggin was thrown into the deep end, meeting with Masatoshi Shima, NCM's representative, who expected to see the logic design of the processor rather than hear an outline from a man who had been on the project less than a day.

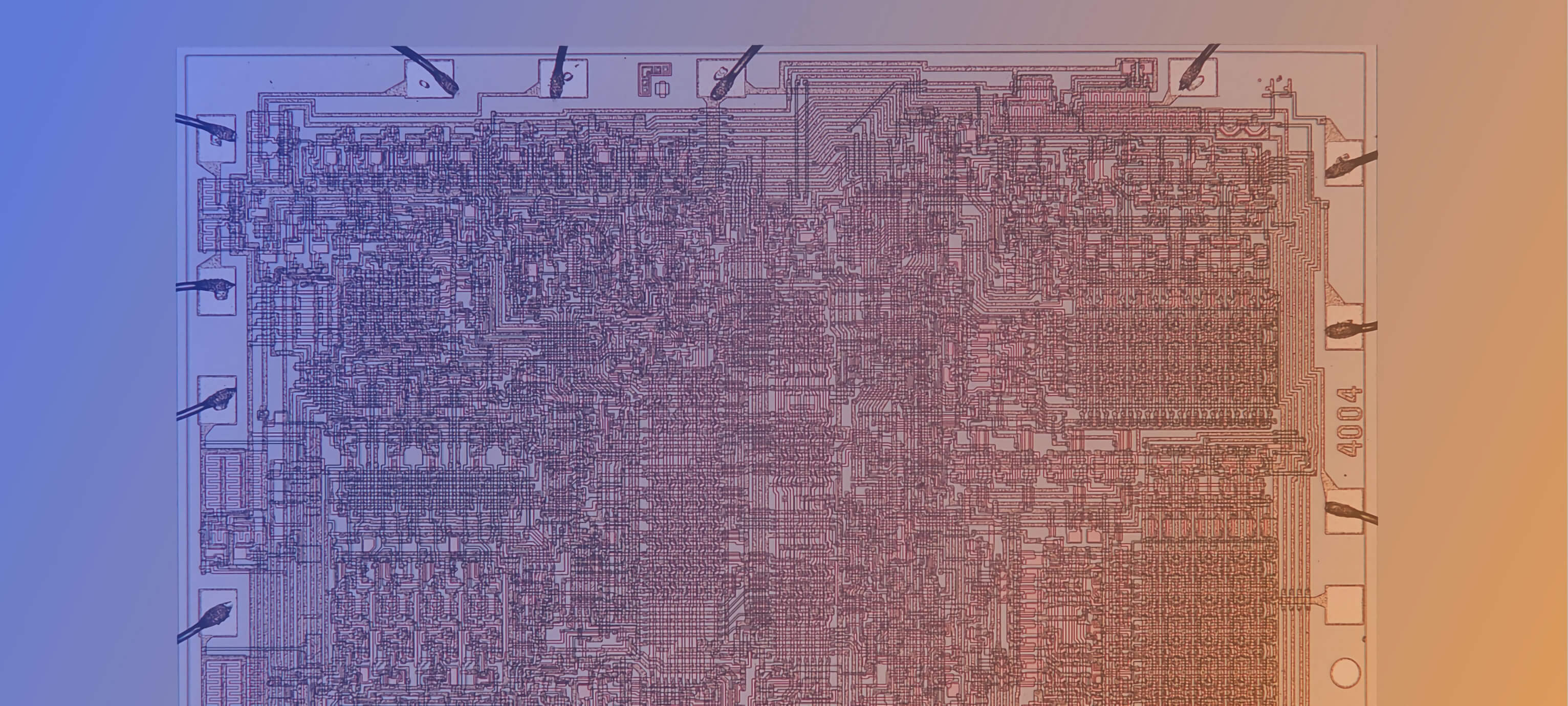

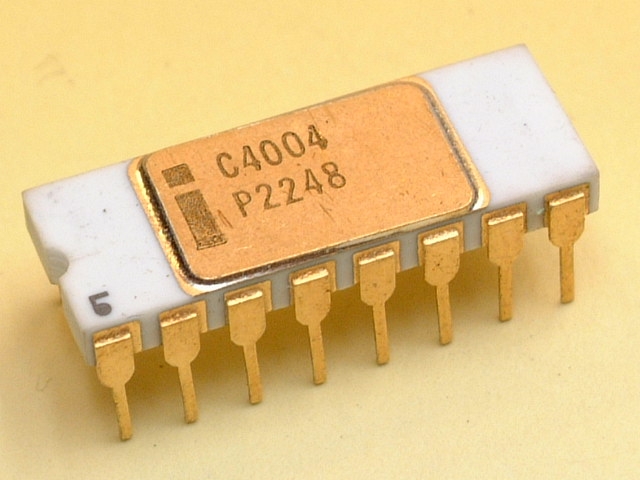

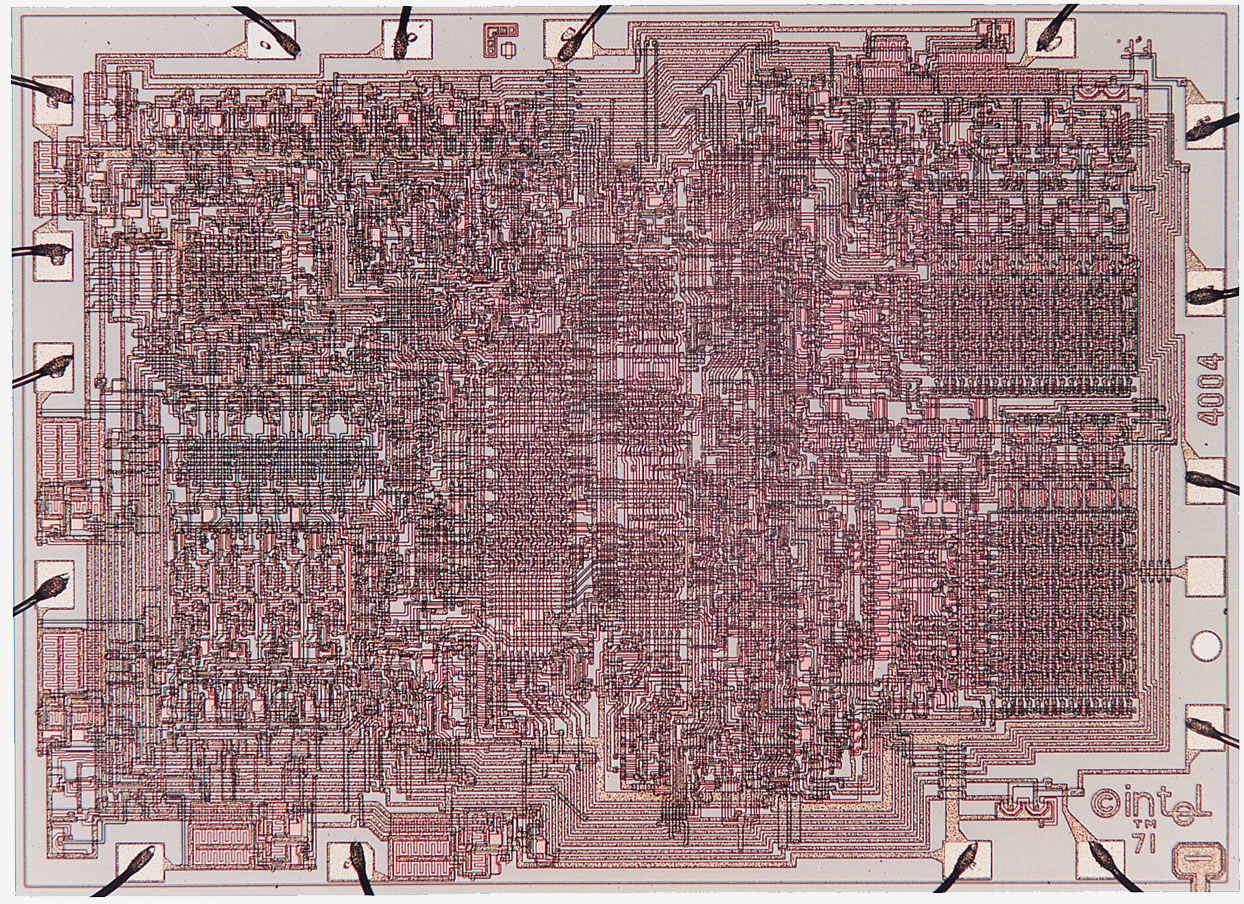

Intel 4004, the first commercial microprocessor, had 2300 transistors and ran at a clock speed of 740KHz. (CPU-Zone)

Faggin's team, which now included Shima for the duration of the design phase, quickly set about developing the four chips. Design for the simplest of them, the 4001 was completed in a week with the layout taking a single draftsman a month to complete. By May, the 4002 and 4003 had been designed and work started on the microprocessor 4004. The first pre-production run came off the assembly line in December but because the vital buried contact layer was omitted from fabrication they were rendered non-working. A second revision corrected the mistake and three weeks later all four working chips were ready for the test phase.

The 4004 might have been a footnote in semiconductor history if it had remained a custom part for NCM, but falling prices for consumer electronics, especially in the competitive desktop calculator market, caused NCM to approach Intel and ask for a reduction in unit pricing from the agreed contract. Armed with the knowledge that the 4004 could have many further applications, Bob Noyce proposed a price cut and a refund of NCM's $60,000 advance payment in exchange for Intel being able to market the 4004 to other customers in markets other than calculators. Thus the 4004 became the first commercial microprocessor.

Two other designs of the era were proprietary to whole systems; Garrett AiResearch's MP944 was a component of the Grumman F-14 Tomcat's Central Air Data Computer, which was responsible for optimizing the fighter's variable geometry wings and glove vanes, while Texas Instruments' TMS 0100 and 1000 were initially only available as a component of handheld calculators such as the Bowmar 901B.

The 4004 might have been a footnote in semiconductor history if it had remained a custom part for NCM.

While the 4004 and MP944 required a number of support chips (ROM, RAM, and I/O), the Texas Instruments chip combined these functions into a CPU – the world's first microcontroller, or "computer-on-a-chip" as it was marketed at the time.

Inside the Intel 4004

Texas Instruments and Intel would enter into a cross-license involving logic, process, microprocessor, and microcontroller IP in 1971 (and again in 1976) that would herald an era of cross-licensing, joint ventures, and the patent as a commercial weapon.

Completion of the NCM (Busicom) MCS-4 system freed up resources for a continuation of a more ambitious project whose origins pre-dated the 4004 design. In late 1969, flush with cash from its initial IPO, Computer Terminal Corporation (CTC, later Datapoint) contacted both Intel and Texas Instruments with a requirement for an 8-bit terminal controller.

Texas Instruments dropped out fairly early, and Intel's 1201 project development, started in March 1970, had stalled by July as project head Hal Feeney was co-opted onto a static RAM chip project. CTC would eventually opt for a then simpler discrete collection of TTL chips as deadlines approached. The 1201 project would languish until interest was shown from Seiko for usage in a desktop calculator and Faggin had the 4004 up and running in January 1971.

In today's environment it seems almost incomprehensible that microprocessors development should play second fiddle to memory, but in the late 1960s and early 1970s computing was the province of mainframes and minicomputers.

In today's environment it seems almost incomprehensible that microprocessor development should play second fiddle to memory, but in the late 1960s and early 1970s computing was the province of mainframes and minicomputers. Less than 20,000 mainframes were sold in the world yearly and IBM dominated this relatively small market (to a lesser extent UNIVAC, GE, NCR, CDC, RCA, Burroughs, and Honeywell – the "Seven Dwarfs" to IBM's "Snow White"). Meanwhile, Digital Equipment Corporation (DEC) effectively owned the minicomputer market. Intel management and other microprocessor companies, couldn't see their chips usurping the mainframe and minicomputer whereas new memory chips could service these sectors in vast quantities.

The 1201 duly arrived in April 1972 with its name changed to 8008 to indicate that it was a follow on from the 4004. The chip enjoyed reasonable success but was handicapped by its reliance on 18-pin packaging which limited its input-output (I/O) and external bus options. Being relatively slow and still using programming by the first assembly language and machine code, the 8008 was still a far cry from the usability of modern CPUs, although the recent launch and commercialization of IBM's 23FD eight-inch floppy disc would add impetus to the microprocessor market in the next few years.

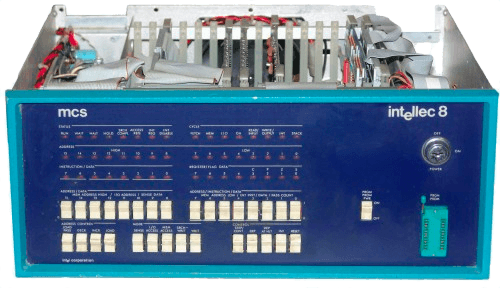

Intellec 8 development system (computinghistory.org.uk)

Intel's push for wider adoption resulted in the 4004 and 8008 being incorporated in the company's first development systems, the Intellec 4 and Intellec 8 – the latter of which would figure prominently into the development of the first microprocessor-orientated operating system – a major "what if" moment in both industries as well as Intel's history. Feedback from users, potential customers, and the growing complexity of calculator-based processors resulted in the 8008 evolving into the 8080, which finally kick-started personal computer development.

This article is the first installment on a series of five. If you enjoyed this, read on as delve into the birth of the first personal computer companies. Or if you feel like reading more about the history of computing, check out our amazing series on the history of computer graphics.