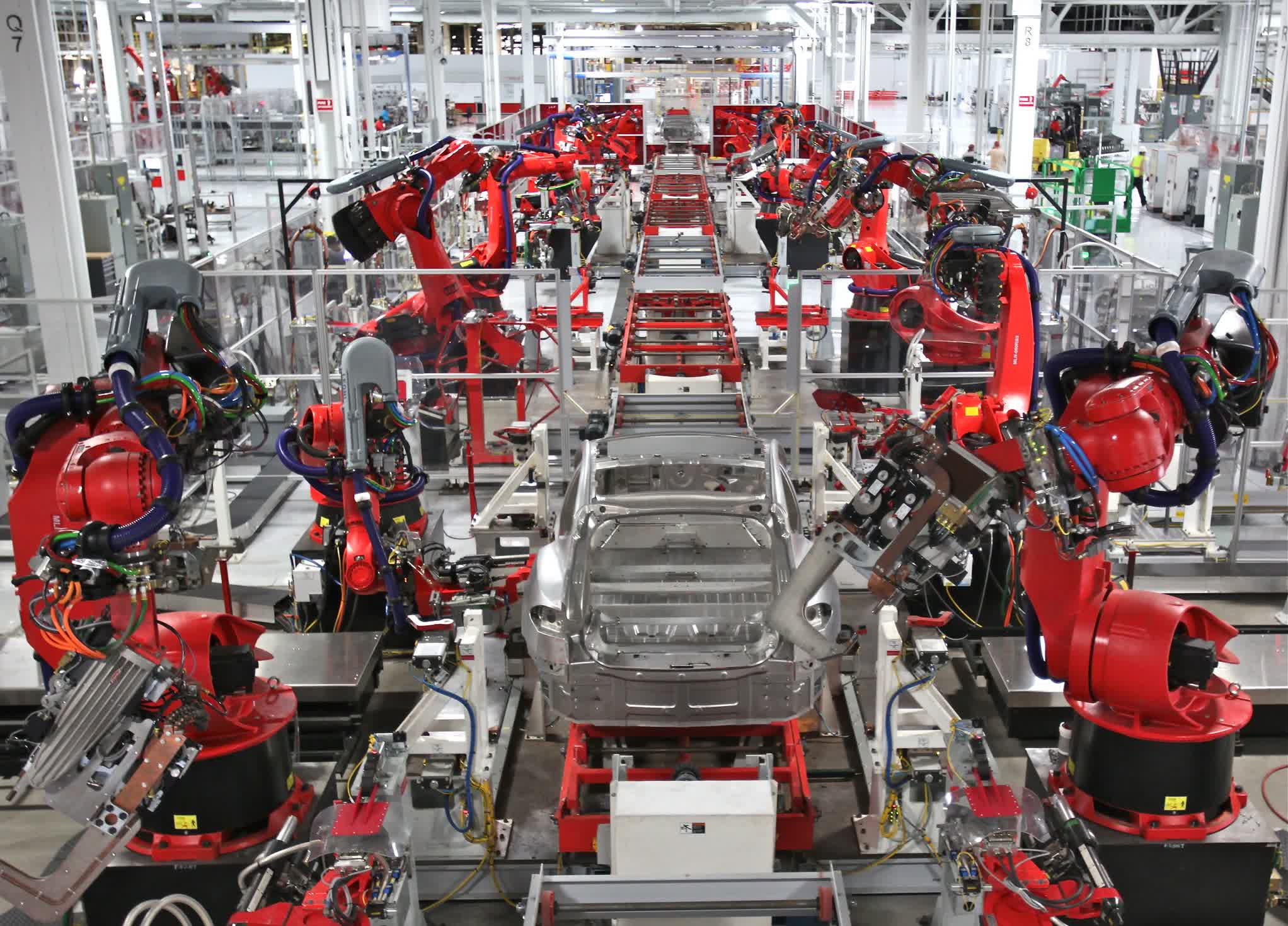

A hot potato: It seems that in addition to concerns about robots taking jobs, we also have to worry about them attacking humans. According to an incident report filed with regulators, a Tesla engineer at the company's gigafactory in Austin, Texas, suffered serious injuries when one of the autonomous machines sank its metal claws into his back and arm, leaving a "trail of blood" along the facility floor.

The Information reports that the incident took place in 2021, when an engineer was programming the software that controls manufacturing robots at the Austin plant.

The report states that the engineer was working on three robots without realizing that only two had been shut down. The third robot, used to grab and move car parts, kept on moving, pinning the engineer against a surface and drawing blood from him with its claw. Another worker hit the emergency stop button, at which point the victim escaped the robot's grasp and fell down a scrap-metal chute. One witness said the injured worker left a trail of blood behind him.

Tesla submitted an injury report to Travis County and federal regulators regarding a worker receiving a "laceration, cut or open wound" from a robot. It states that the engineer's injuries didn't require him to take any time off work.

The Information notes that the federal Occupational Safety and Health Administration inspected Tesla's Austin factory just once a year in 2021 and 2022, the most recent inspections coming after a complaint was filed about a subcontractor suffering a heat-related injury. Tesla's Fremont, California, factory received nine safety inspections each year in 2021 and 2022, and four so far in 2023.

According to analysis of federal data carried out by the publication, Nearly one out of every 21 workers at the Austin factory were injured on the job last year. Similar factories record a much lower median injury rate of 1 out of every 30. The Fremont facility's rate was even worse: 1 in 12 workers were hurt while working last year.

Several current and former Tesla workers said that the company regularly cut corners on construction, maintenance, and operations in a way that puts them at risk of injury. Sources also say management's demands for increased production rates often result in safety issues.

Tesla's workplace safety problems stretch back years. In 2018, the automaker was accused of under-reporting the injuries its workers received while working at the Fremont factory, leading to an investigation by the California Division of Occupational Safety and Health.

There have also been reports of heavy machinery falling near production line workers, employees falling ill after exposure to toxins such as ammonia, a worker getting their ankle caught under a moving cart last summer, and someone being struck in the head by a metal object.

The slight irony about the recent report is that protecting workers' safety is often one of the justifications companies spout when introducing robots to factory floors. Amazon, another firm with a questionable safety record, recently added two new robots to its warehouses, including the humanoid-like Digit. Their maker insists they are meant to help humans, not replace them.

Center image: Steve Jurvetson