In brief: Elon Musk puts a lot of faith in Tesla's Optimus humanoid robot. Not only does the CEO believe it will drive the EV firm's valuation into the trillions, but he also expects thousands of the bots working at Tesla – and other companies' – factories. However, the former Optimus team lead thinks these robots aren't the right fit for high-speed, repetitive factory work.

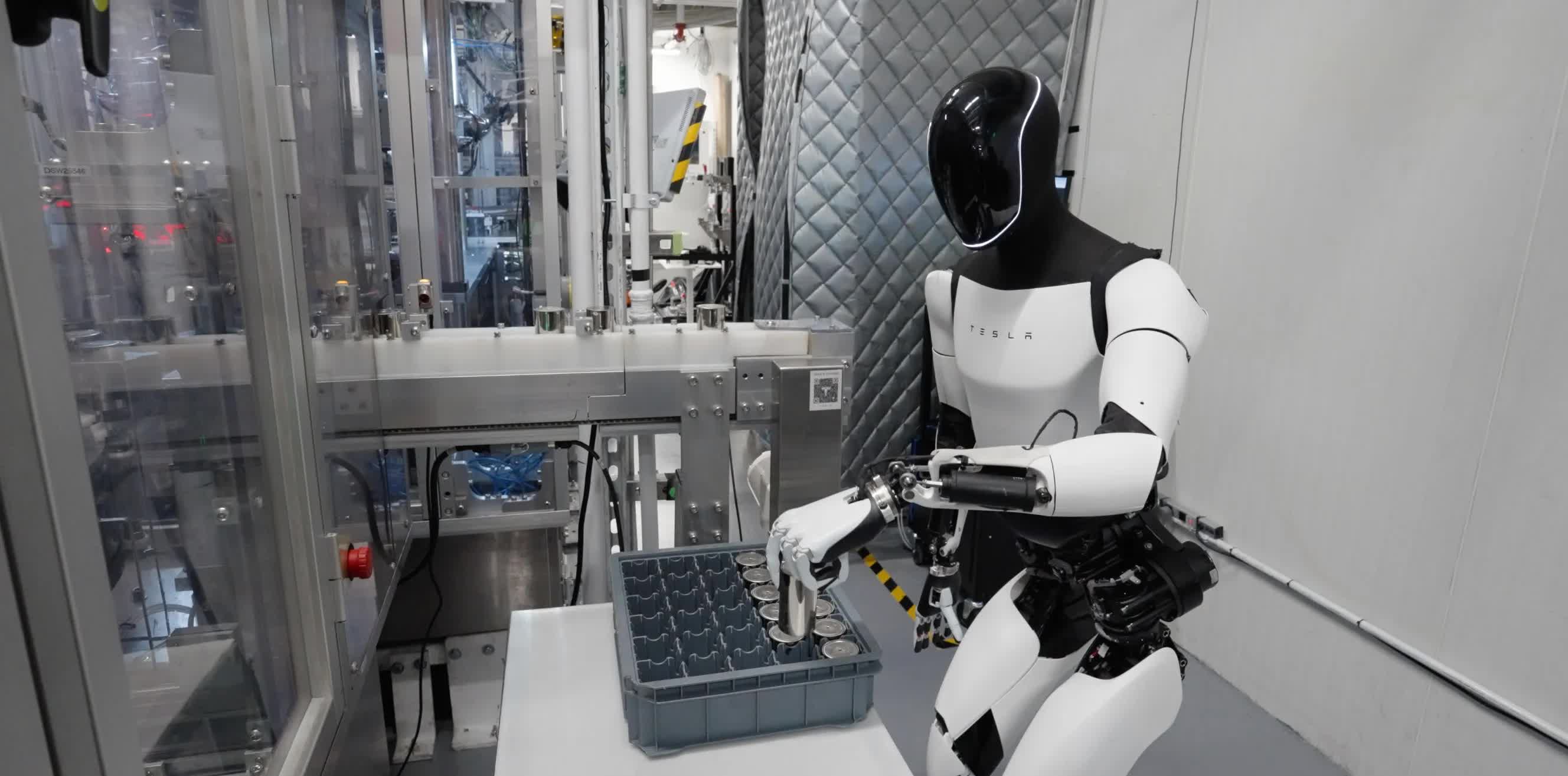

In August 2021, Tesla announced that it was creating a general-purpose, bipedal, humanoid robot capable of performing tasks that are unsafe, repetitive, or boring for humans to carry out.

The robot has undergone several design changes since then, with improvements in speed, stability, weight, balance, and other areas.

Last year, Musk made the bold claim that there will be at least one humanoid robot for every person in the world and that Tesla will control a massive share of this market, pushing its value to $25 trillion. He later said that the robots would be put to work in Tesla factories helping build its vehicles – presumably lowering costs by replacing human workers.

Last week, Musk told CNBC that he expects thousands of Optimus bots will be working in Tesla factories by the end of the year, and he was confident that it would be producing millions of the 5-foot, 8-inch machines by the end of 2030.

Musk has a habit of giving optimistic timelines for Tesla products, as the Cybertruck illustrated. The fact that the machines were revealed to be remotely controlled at the "We, Robot," event last December, where they mingled with guests, served drinks, and even danced, doesn't exactly inspire confidence.

Optimus appears to be remotely controlled... for now! pic.twitter.com/L89fz8cnOM

– The Kilowatts �-â¡ï¸Â (@klwtts) October 11, 2024

Chris Walti, the former team lead Optimus, said he has a different view from his former boss. He told Business Insider that humanoid robots like Tesla's were less effective in warehouses, logistics, and manufacturing environments.

"It's not a useful form factor. Most of the work that has to be done in industry is highly repetitive tasks where velocity is key," said Walti.

Walti does have a motive to be pessimistic about these robots. He left Tesla in 2022 to found Mytra, a company that makes slab-like robots for transporting heavy payloads in warehouses using massive modular structures called "cells." He said these were much simpler form factors than humanoids.

Walti said the wider range of movements in humanoid robots have led to engineering problems more difficult to solve than even self-driving cars. He added that robotics had not advanced enough to deploy humanoid robots properly.

Walti noted that the humanoid shape itself was a big part of the problem. Humans "evolved to escape wolves and bears. We weren't designed to do repetitive tasks over and over again. So why would you take a hyper suboptimal system that really isn't designed to do repetitive tasks and have it do repetitive tasks?"

Despite Walti's concerns, more humanoid robots are finding their way into factories and warehouses. GXO Logistics signed a multi-year agreement with Agility Robotics last year to begin deploying Digit in its operations. Digit is the 5-foot 9-inch, 140-pound humanoid robot that Amazon first introduced into its warehouses in 2023.

GXO is also in the process of testing robots from Apptronik. In February, the robot maker announced a pilot partnership with American firm Jabil to test its Apollo humanoid robots. Jabil agreed to begin producing the robots in its factories, meaning that these robots could eventually be put to work building more of themselves.

In January last year, BMW announced that humanoid robots would begin working at its vehicle manufacturing plants, starting in Spartanburg, South Carolina.

Some analysts believe that wide-scale deployment of humanoid robots in these industries will take place before the end of the decade. What that would mean for a segment that employs millions is unclear.