Forward-looking: A new chapter in materials science is unfolding at MIT, where researchers have developed a fully autonomous robotic system designed to accelerate the search for advanced semiconductors. This technology aims to address a long-standing challenge: the slow pace of manually measuring key properties in new materials, which has limited progress in fields such as solar energy.

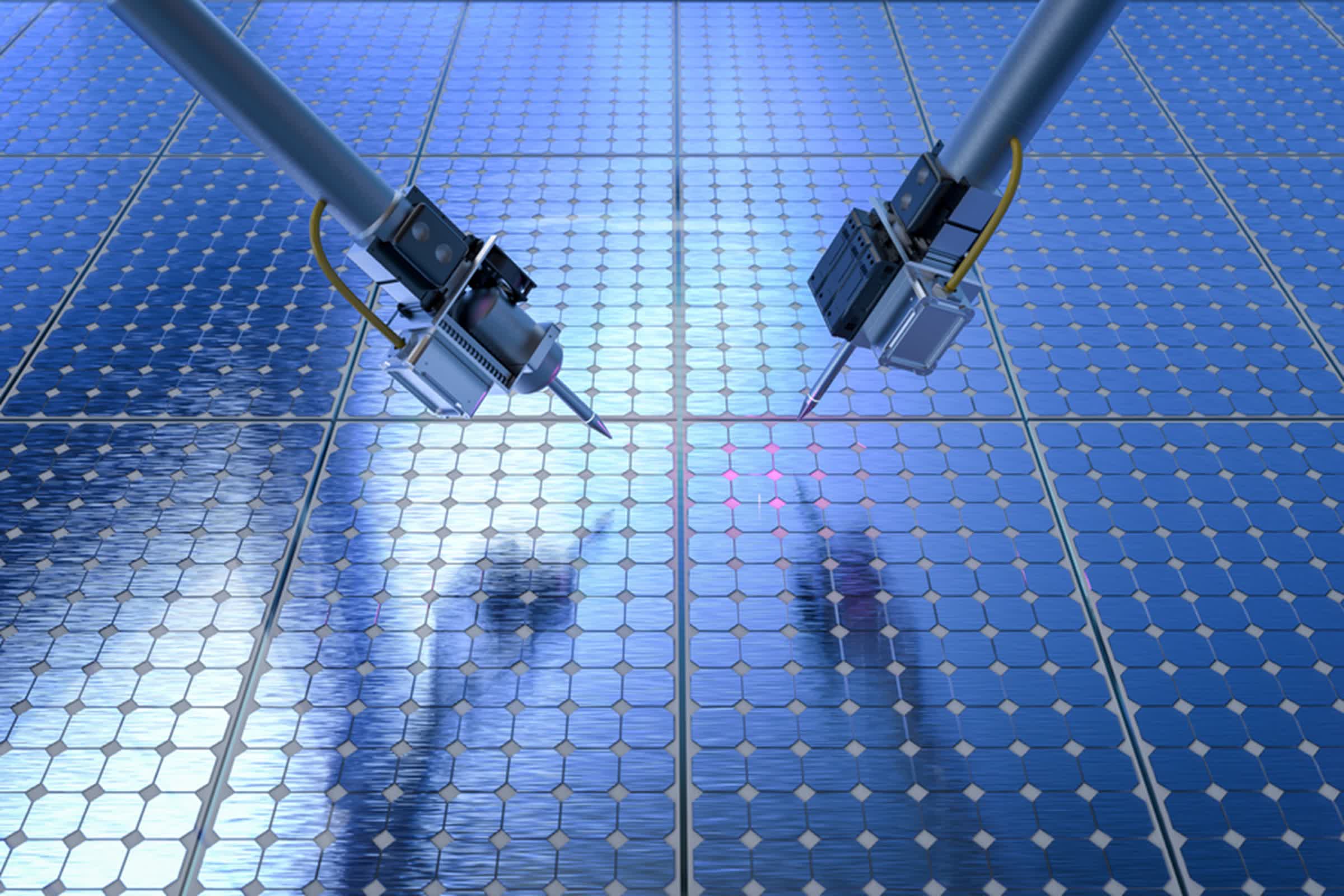

At the heart of the system is a robotic probe capable of measuring photoconductance, a property that reveals how a material responds to light. By integrating expert knowledge from materials scientists into a machine-learning model, the robot can determine the most informative points to probe on a sample. This approach, paired with a specialized planning algorithm, enables the robot to move quickly and efficiently between contact points.

In a rigorous 24-hour test, the robot performed more than 125 unique measurements per hour, surpassing the precision and reliability of previous artificial intelligence-based methods. This leap in speed and accuracy could accelerate the development of more efficient solar panels and other electronic devices.

"I find this paper to be incredibly exciting because it provides a pathway for autonomous, contact-based characterization methods," said Tonio Buonassisi, a professor of mechanical engineering and senior author of the study. "Not every important property of a material can be measured in a contactless way. If you need to make contact with your sample, you want it to be fast and you want to maximize the amount of information that you gain."

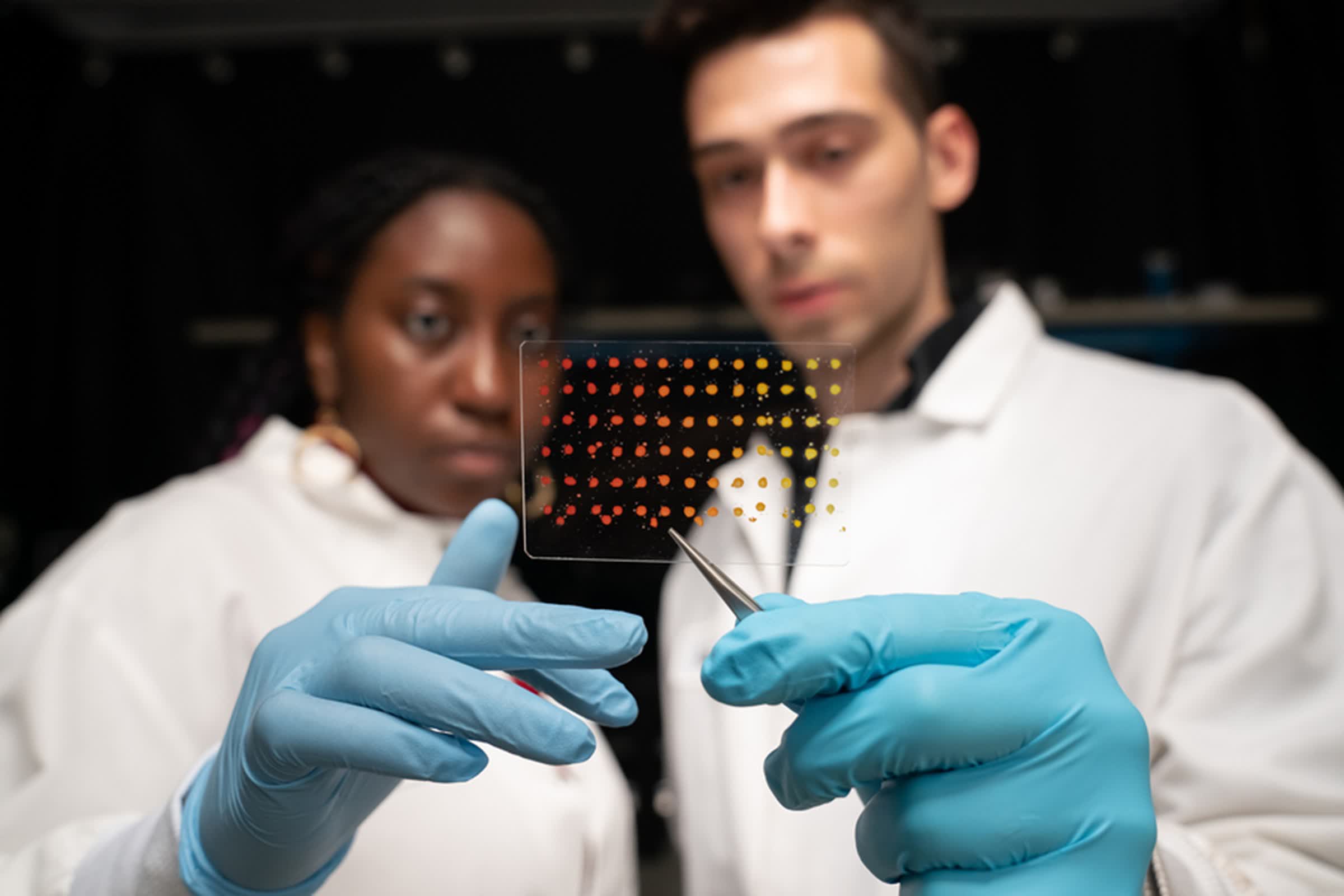

The research team, led by graduate student Alexander Siemenn, along with postdoctoral researchers Basita Das and Kangyu Ji, as well as graduate student Fang Sheng, published their findings in Science Advances.

The journey toward this innovation began in 2018, when Buonassisi's lab set out to build a fully autonomous materials discovery laboratory. The efforts have recently focused on perovskites, a class of semiconductors used in solar panels. While previous advances allowed for rapid synthesis and imaging-based analysis, accurately measuring photoconductance still required direct contact with the material.

"To allow our experimental laboratory to operate as quickly and accurately as possible, we had to come up with a solution that would produce the best measurements while minimizing the time it takes to run the whole procedure," Siemenn explained.

The system begins by capturing an image of the perovskite sample using its onboard camera. Computer vision then divides the image into segments, which are analyzed by a neural network model that incorporates the expertise of chemists and materials scientists. "These robots can improve the repeatability and precision of our operations, but it is important to still have a human in the loop. If we don't have a good way to implement the rich knowledge from these chemical experts into our robots, we are not going to be able to discover new materials," Siemenn added.

The neural network identifies the best probe contact points based on the sample's shape and composition. These points are then fed into a path planner that determines the most efficient route for the robot to follow. The adaptability of this approach is crucial, as the samples often have unique shapes. "It is almost like measuring snowflakes – it is difficult to get two that are identical," Buonassisi said.

A key innovation is the self-supervised nature of the neural network, which selects optimal contact points directly from sample images without needing labeled training data. The team also improved the path planning algorithm by introducing a small amount of randomness, which helped the robot find shorter paths.

"As we progress in this age of autonomous labs, you really do need all three of these expertise – hardware building, software, and an understanding of materials science – coming together into the same team to be able to innovate quickly. And that is part of the secret sauce here," Buonassisi said.

After building the system, the researchers tested each component. The neural network outperformed seven other AI-based methods in identifying contact points with reduced computation time, and the path planner consistently generated shorter routes than competing algorithms. In a full 24-hour autonomous experiment, the robot completed over 3,000 photoconductance measurements, identifying both high-performing areas and regions of degradation in the materials.

"Being able to gather such rich data that can be captured at such fast rates, without the need for human guidance, starts to open up doors to be able to discover and develop new high-performance semiconductors, especially for sustainability applications like solar panels," Siemenn said.

Looking ahead, the team plans to refine the system further as it works toward establishing a fully autonomous laboratory for materials discovery. The project is supported by organizations including First Solar, Eni through the MIT Energy Initiative, MathWorks, the University of Toronto's Acceleration Consortium, the US Department of Energy, and the US National Science Foundation.