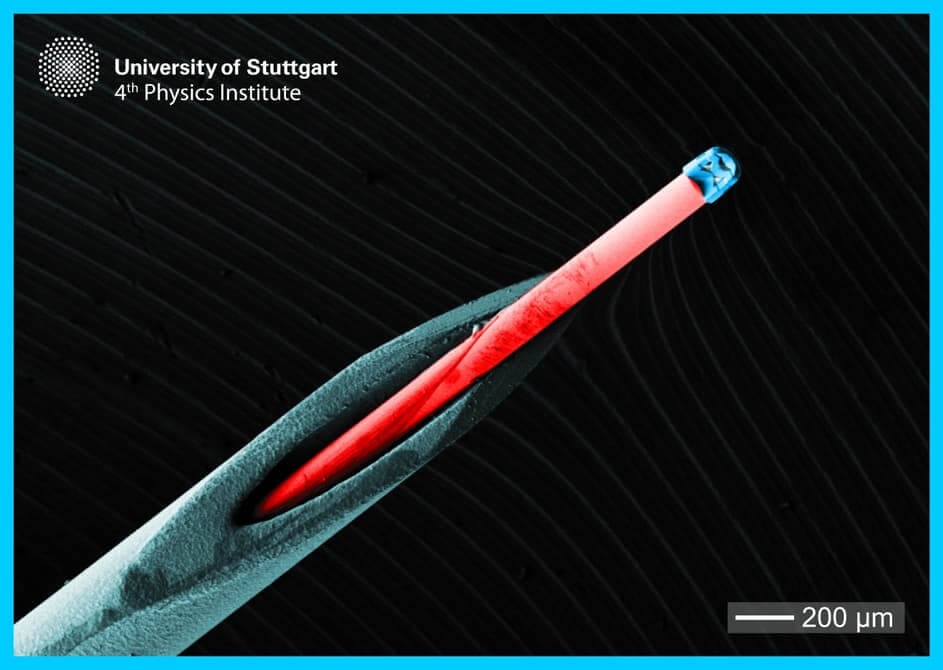

Not only is getting a camera into the human body a very invasive experience, it's not always possible when it comes to examining certain areas. But researchers at the University of Stuttgart in Germany have developed a camera so tiny it can be injected into a person using a syringe.

It took Timo Gissibl, Simon Thiele, Alois Herkommer, and Harald Giessen "a few hours to design, manufacture and test" the 3D-printed three-lens camera that measures an incredible 100 micrometers (0.004 inches) across, smaller than a grain of salt.

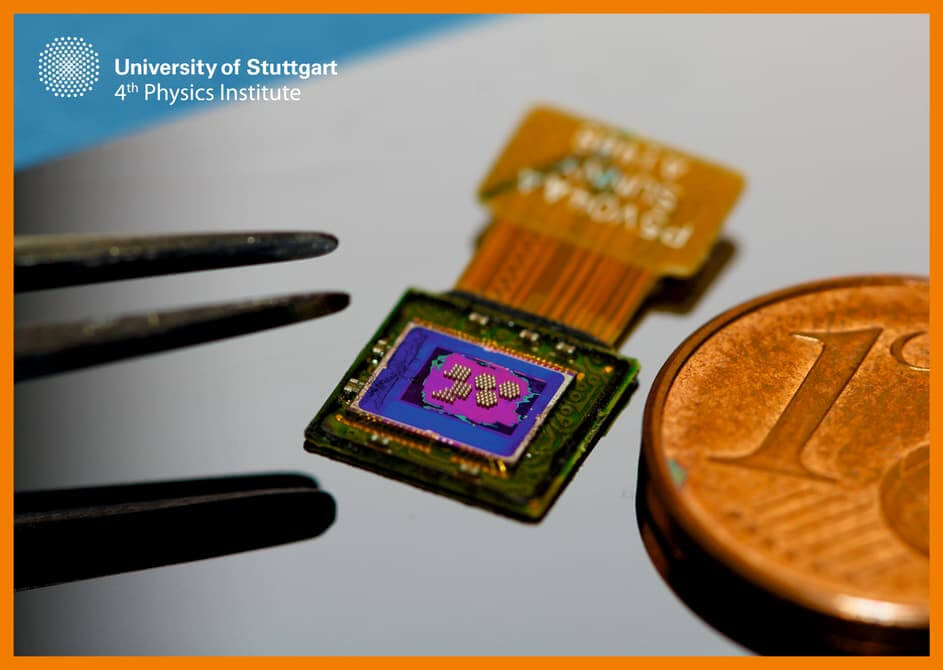

The camera, which can focus on images from a distance of 3mm, currently needs to be tethered to a 1.7 meter (5.5 foot) length of optical fiber. Its minute dimensions mean it could be injected directly into human organs, even the brain - though it still needs more testing and the green light from regulators.

Manufacturing the camera involves blasting a femtosecond laser into a light-sensitive liquid that hardens at the absorption of each pulse. Any unexposed material is then washed away with a solvent, leaving the lens element behind. The process also allows unconventional lens shapes to be printed for specific purposes.

"Endoscopic applications will allow for non-invasive and non-destructive examination of small objects in the medical as well as the industrial sector," the team write.

Away from medical applications, the cameras can be used to create miniature illumination systems, be placed into tiny robots and drones, and enable the creation of smaller sensors for autonomous vehicles. There's also the numerous, and scary, surveillance possibilities they offer.

The researchers believe that the new technique could be a game changer for optics manufacturing. "The time from the idea, the optics design, a CAD model, to the finished, 3D-printed micro-objectives is going to be less than a day," says Professor Harald Giessen, from the University of Stuttgart's 4th Physics Institute. "We are going to open potentials just like computer-aided design and computer-integrated manufacturing did in mechanical engineering a few years ago."