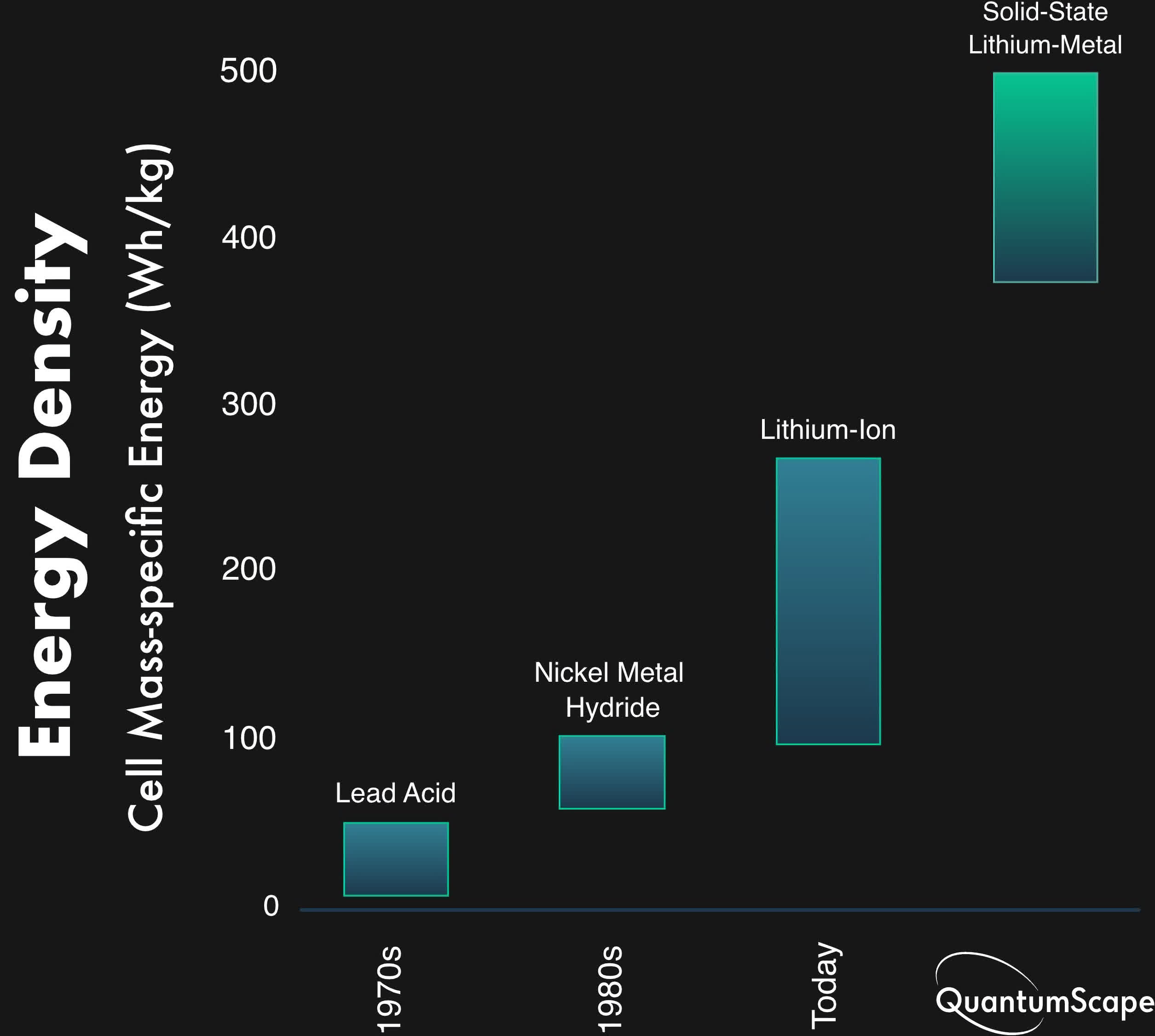

Something to look forward to: Solid-state batteries are still nebulous outside of the lab. Still, automakers are scrambling to be the first in the race to build the first electric car to take advantage of the added energy density and better safety when compared to lithium-ion designs. To that end, they're investing in companies like QuantumScape, Solid Power, and Sakuu to develop manufacturing techniques that either build on existing approaches or rely on new additive manufacturing technology.

Earlier this year, an MIT study revealed that lithium-ion battery costs have fallen by more than 97 percent since its commercial introduction almost 30 years ago. Not only that, but industry watchers are optimistic that by 2025 lithium-ion battery manufacturing capacity will have tripled while the price per kilowatt-hour is expected to dip below $100.

The dip has spurred automakers to get serious about making electric cars, but the fact of the matter is that price is only part of the equation of making it a better choice for consumers and the environment. The importance of safety cannot be overstated, as evidenced by GM's recall last year for more than 68,000 Chevy Bolts. On that front, researchers are hard at work developing a new cathode coating that not only makes lithium-ion batteries safer but could also improve their energy density.

Various companies are banking on solid-state batteries to solve these issues. Such is the case of the 3D-printing startup called Sakuu (formerly KeraCel) that claims to have developed a lithium-metal solid-state battery that offers equal or better performance compared to the lithium-ion batteries currently in use.

Sakuu's cell has a capacity of 3Ah and is made using the company's additive manufacturing technology, set for a commercial launch in the coming months. On a second generation, Sakuu plans to minimize the overall volume of all the elements using a binder jet printing process developed by MIT. This method allows the company to deposit thin layers of metal and ceramic in a single build.

The process is relatively slow, but the results are batteries that are half the size and one-third the weight of their lithium-ion counterparts, which is no small feat. Sakuu says it plans to begin mass-producing the new batteries in early 2022 and is currently exploring higher voltage cathodes for an up to 25 percent boost in energy density. The initial capacity will be a relatively modest 1 GWh, but if achieved, it will represent a milestone in the commercialization of solid-state batteries.

Another important factor for batteries is longevity, and this has sparked a fierce debate about how we're going to deal with dead batteries from electric cars as they pile up. The current crop of EV batteries isn't designed to be recycled. Consumer Reports estimates these will last anywhere between 100,000 to 200,000 miles before their ability to hold a charge degrades significantly. Last year, Tesla battery supplier CATL promised to begin manufacturing batteries that could last for 1.24 million miles before they need to be replaced.

In the end, the solution to the problem will most likely be a combination of better battery chemistry, innovative manufacturing, and the creative reuse and recycling of old batteries.

As it stands, solid-state lithium-metal battery designs are still unproven in terms of stability, despite offering better energy density and increased safety when compared to lithium-ion. Companies like QuantumScape, Solid Power, and Samsung say they have a few solutions for this issue. Most are targeting a 2022-2023 timeline for mass production of the new battery cells, so it won't be long before we can see if they'll live up to the hype.