In brief: The chip shortage has been a constant source of bad news for tech companies and consumers. However, the good news is the industry is slowly adapting to the unrelenting demand and even exploring ways to create a more resilient supply chain.

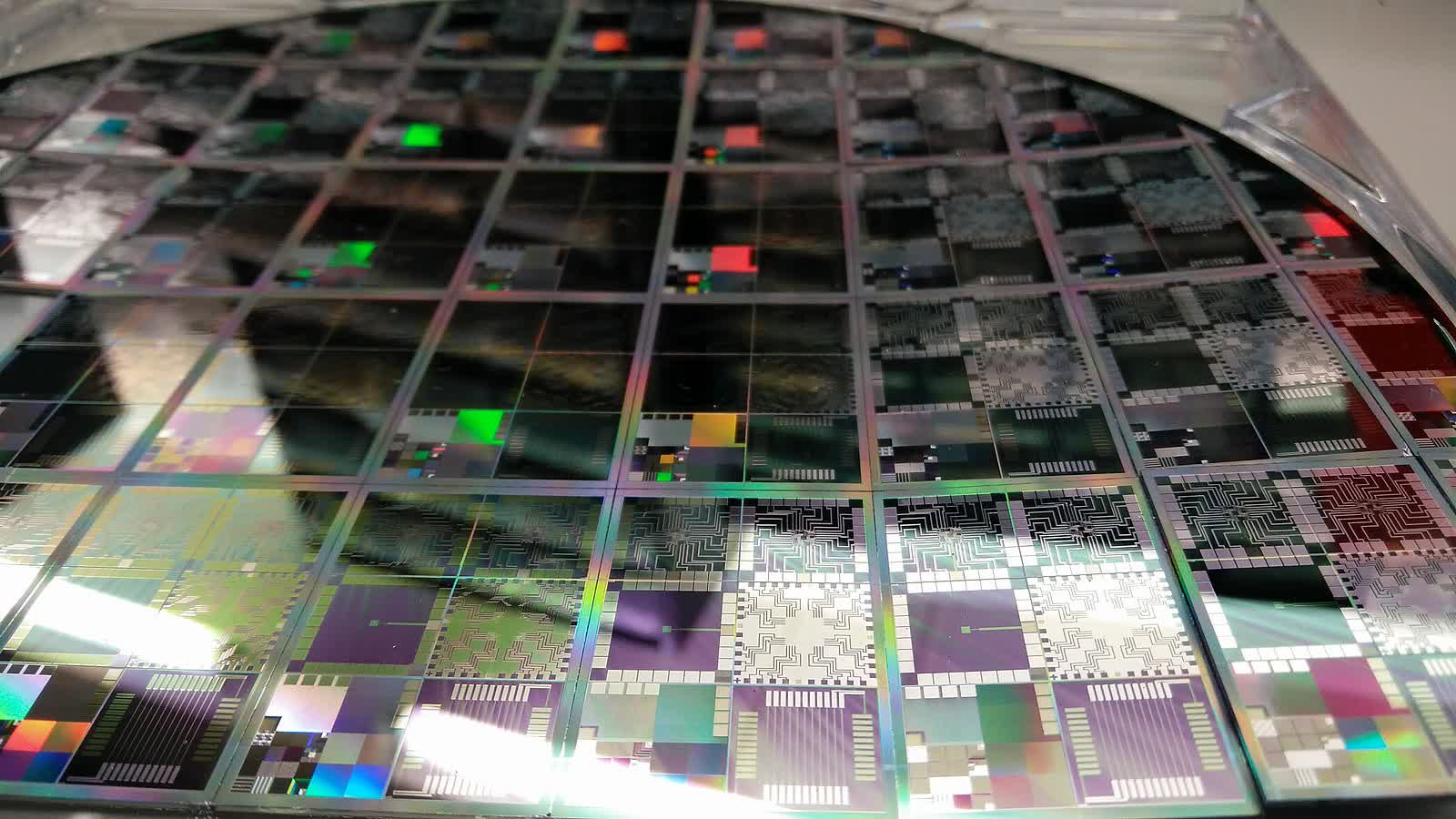

GlobalWafers recently announced it would expand its manufacturing capacity between 2022 and 2024 in a project with capital expenditures totaling NT$100 trillion (approximately $3.6 billion). The company thought it a prudent move after it failed a planned $4.98 billion takeover of German wafer supplier Siltronic.

More details about the expansion plans are expected to be revealed in March, including factory locations. In a statement, GlobalWafers CEO Doris Hsu said the company would evaluate several possible sites in the US, the EU, and Asia. If all goes well, the first production lines will be operational in the second half of 2023.

Elsewhere, Toshiba is also looking to expand its capacity for 300-millimeter wafers for power semiconductors. The Japanese company wants to build a new manufacturing facility in the Ishikawa Prefecture that could become operational in 2024. This expansion would help Toshiba deliver capacity 2.5 times greater than what the company offered in 2021.

The importance of continued investments in manufacturing capacity cannot be overstated. Earlier today, Ford said it would need to cut or suspend production at several facilities over the ongoing chip shortage. Sony has also cut its PS5 shipments forecast, and some tech industry leaders believe the situation won't improve until 2023.