Forward-looking: Researchers from Boston University, UC Berkeley, and Northwestern University have developed an integrated system that combines electronic, photonic, and quantum components on a single semiconductor chip – a first in quantum technology, according to a new study published in Nature Electronics. The team's work presents a method for mass-producing "quantum light factories" using the same semiconductor manufacturing processes commonly employed in conventional electronic devices.

The new chip integrates quantum light sources and electronic controllers using a standard 45-nanometer semiconductor process. This approach paves the way for scaling up quantum systems in computing, communication, and sensing, fields that have traditionally relied on hand-built devices confined to laboratory settings.

"Quantum computing, communication, and sensing are on a decades-long path from concept to reality," said Miloš Popović, associate professor of electrical and computer engineering at Boston University and a senior author of the study. "This is a small step on that path – but an important one, because it shows we can build repeatable, controllable quantum systems in commercial semiconductor foundries."

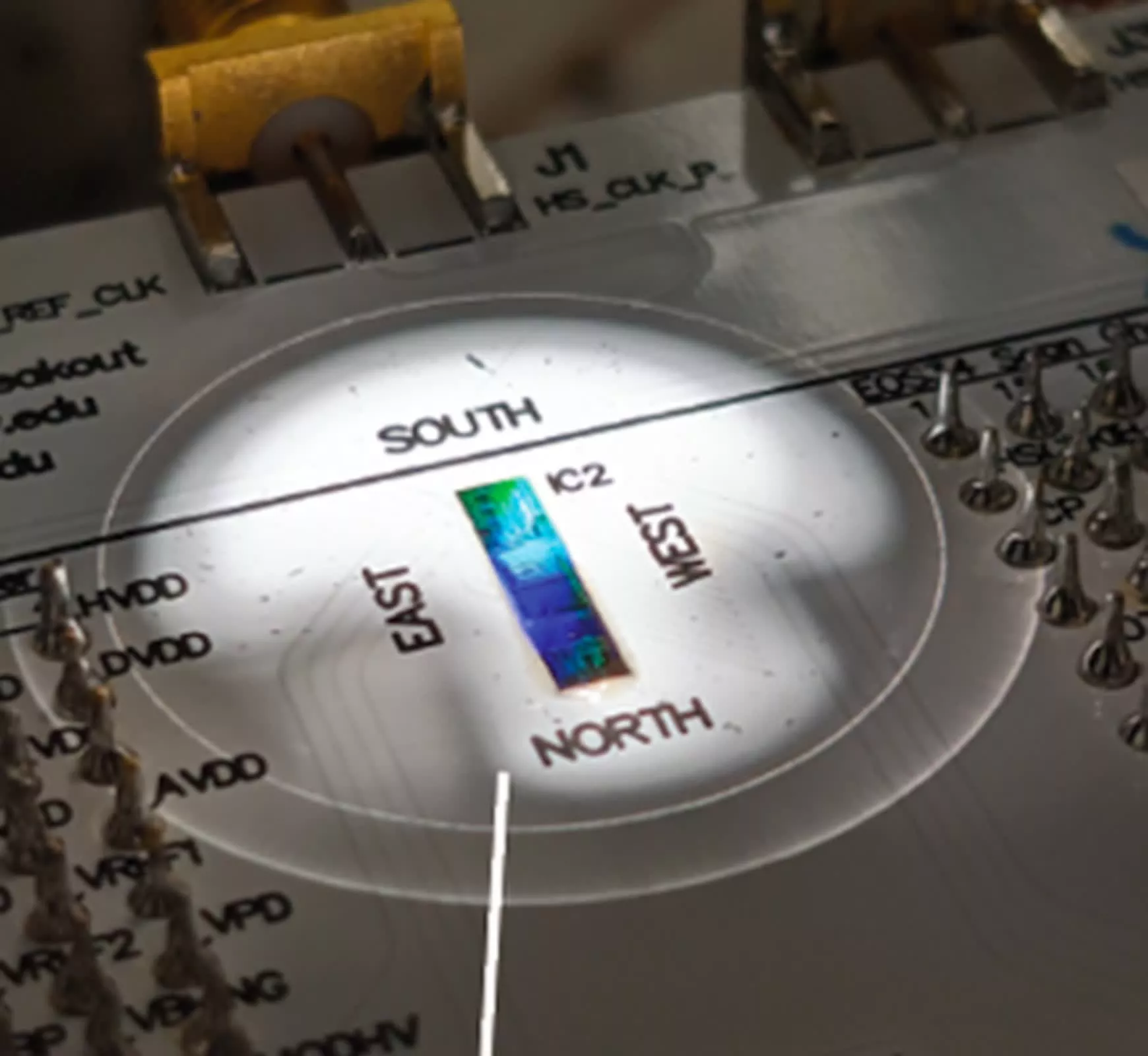

The chip at the center of the study functions as an array of quantum light sources known as microring resonators. Each of these devices – measuring less than a millimeter across – can generate tightly correlated pairs of photons, a crucial resource for quantum operations.

Microring resonators operate by synchronizing with incoming laser light, but their performance is highly sensitive to even slight temperature fluctuations or manufacturing variations – factors that can easily disrupt the delicate quantum processes they support.

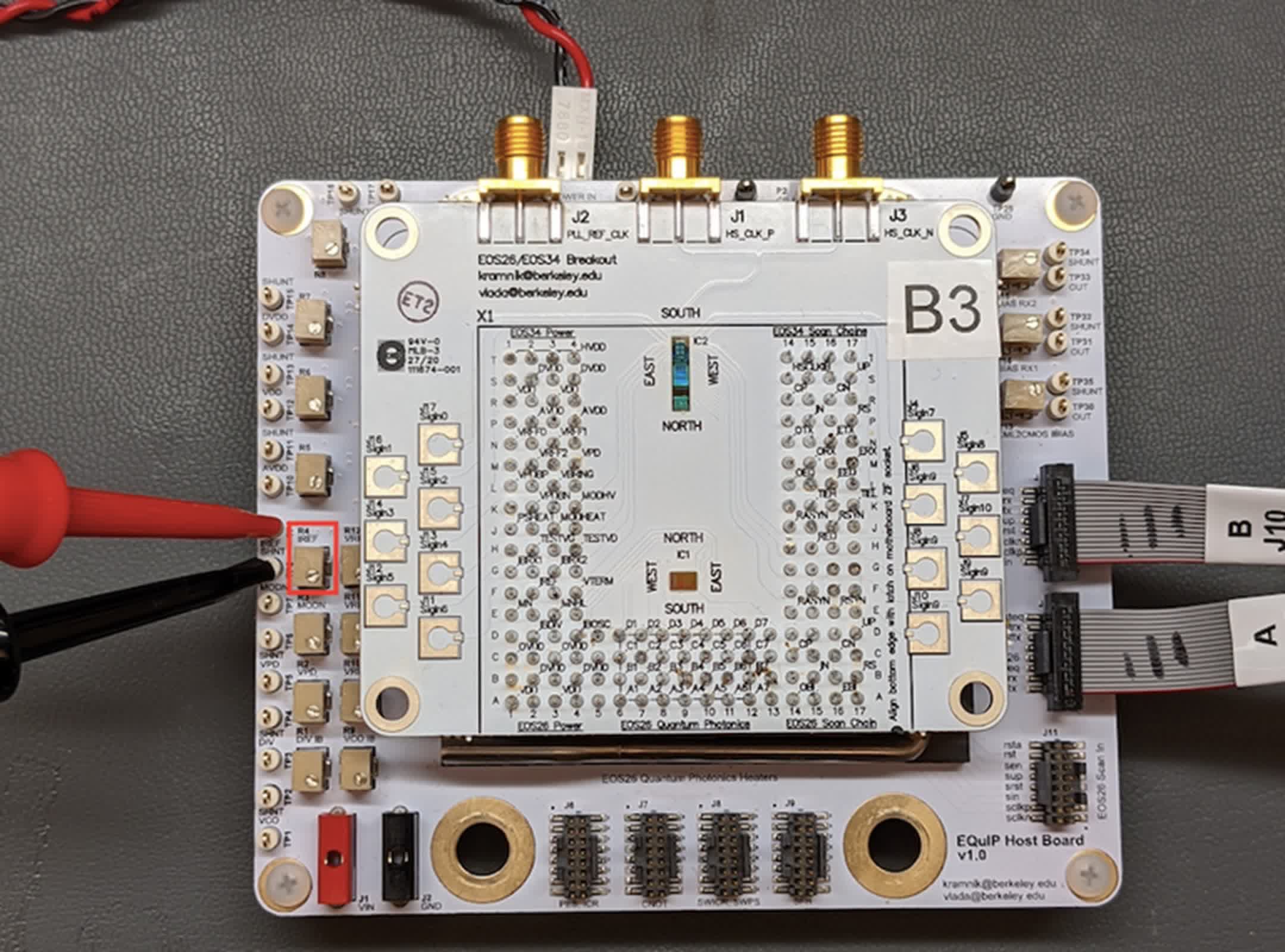

To address these challenges, the researchers developed an integrated control system capable of stabilizing the microring resonators in real time. The chip includes 12 resonators that can operate in parallel, each monitored by built-in photodiodes that track alignment with the laser. On-chip heaters and logic circuits automatically adjust the resonators whenever temperature shifts or other disturbances threaten their performance.

"What excites me most is that we embedded the control directly on-chip – stabilizing a quantum process in real time," says Anirudh Ramesh, a PhD student at Northwestern who led the quantum measurements. "That's a critical step toward scalable quantum systems."

This focus on stabilization is essential to ensure that each light source performs reliably under varying conditions. Imbert Wang, a doctoral student at Boston University specializing in photonic device design, highlighted the technical complexity.

"A key challenge relative to our previous work was to push photonics design to meet the demanding requirements of quantum optics while remaining within the strict constraints of a commercial CMOS platform. That enabled co-design of the electronics and quantum optics as a unified system."

By achieving tight feedback control over each light source, the chip can maintain consistent performance despite temperature fluctuations or minor manufacturing variations. The entire device was fabricated using a commercial complementary metal-oxide-semiconductor process and was developed in collaboration with industry partners such as GlobalFoundries and the Silicon Valley startup Ayar Labs.

The project required deep interdisciplinary collaboration. "The kind of interdisciplinary collaboration this work required is exactly what's needed to move quantum systems from the lab to scalable platforms," says Prem Kumar, professor at Northwestern and a pioneer in quantum optics. "We couldn't have done this without the combined efforts in electronics, photonics, and quantum measurement."