LSI SandForce has detailed the new error correction methods built into their next-generation solid state drive controller called SHIELD. At the Flash Memory Summit in Sana Clara, CA, SandForce unveiled the new technology which is intended to extend the life of NAND flash memory built with smaller lithography processes, reports Tech Report.

Flash memory, like other chips, is continually being reduced in size to lower manufacturing cost and power consumption. While this reduction in size has a positive effect on cost per gigabyte for memory, it has the negative consequence of making NAND more susceptible to errors.

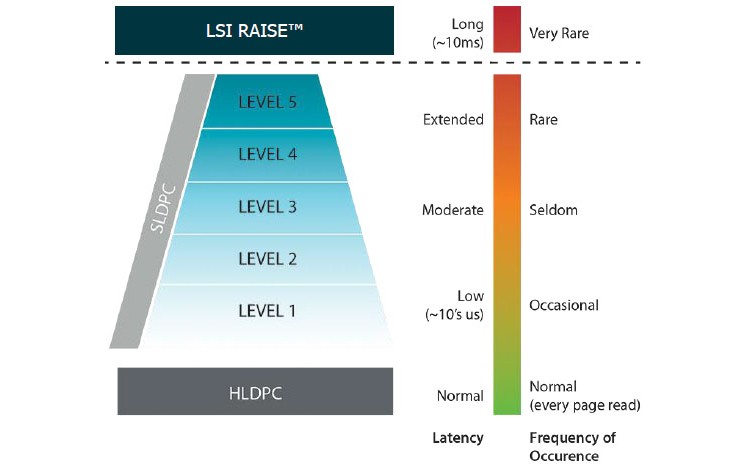

LSI SandForce developed SHIELD to combat these issues through multiple layers of error correction. The first error correction stage is a "hard" low-density parity check, or HLDPC, applied to read requests. HLDPC has low overhead and doesn't impact performance, but isn't comprehensive enough to catch all errors.

Errors that make it past HLDPC are handled by five levels of "soft" parity checks. SLDPC layers use advanced noise handling and signal processing for error correction, and each layer adds progressively more latency.

SHIELD only kicks in when the drive deems it necessary, and determines the proper level of error correction to use based on some parameters that LSI hasn't yet disclosed. If errors continue to propagate through all five layers of SLDPC, the final level of SHIELD kicks in, called RAISE.

RAISE operates with a RAID-like redundancy scheme that is similar to what's employed with current SandForce controllers, but adds 10 milliseconds of latency. LSI said that this last level of error correction is used sparingly and only when necessary because of the additional processing time.

According to Tech Report, the new chips will be sent to manufacturers for sampling in the third quarter of 2013, so it's possible that new LSI SandForce chips equipped with SHIELD will be on the market by the end of the year.