The big picture: Perovskite is a mineral consisting mainly of calcium titanate. The term can also refer to a class of materials with the same crystal structure type, known as the perovskite structure. Perovskite is a highly versatile material utilized in numerous applications and is being hailed as a potential solution for enhancing solar cell efficiency.

According to recent studies, incorporating a perovskite layer on top of a silicon base could significantly enhance the efficiency of energy absorption in solar panels. However, the potential number of perovskite materials is vast, with each technological improvement introducing a new variant.

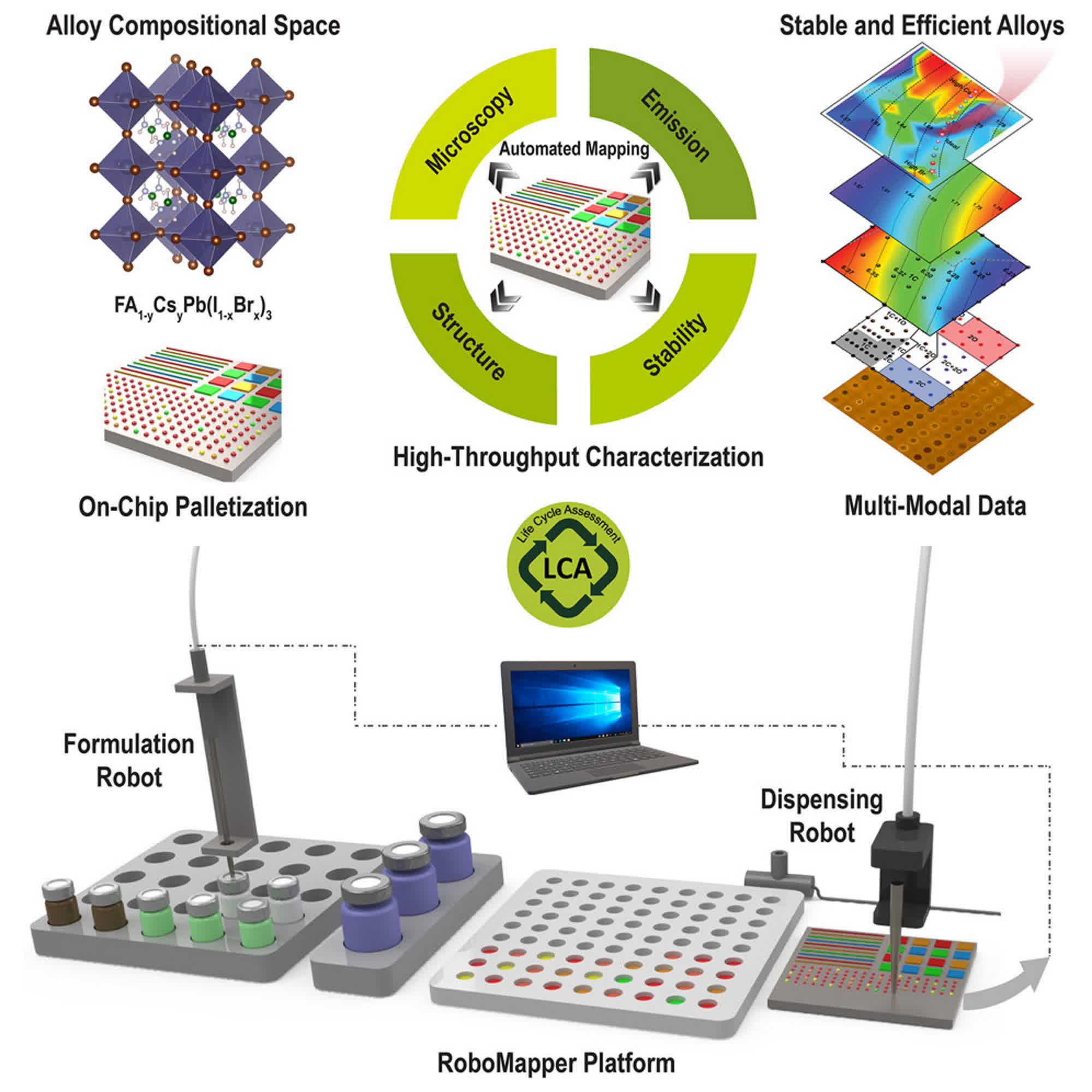

Researching new variations of perovskite materials is an immensely labor-intensive endeavor, as confirmed by Aram Amassian, a professor at North Carolina State University (NCSU). Amassian and his team conducted a study using a novel testing robot they named RoboMapper. The bot has the potential to accelerate research on novel perovskite materials by a factor of 14 compared to manual selection methods, and by a factor of nine when compared to other automation-based approaches.

RoboMapper is an ink-based self-testing device comprised of two primary components. The initial bot blends an ink mixture using a set of foundational chemicals, combining them in various proportions to create numerous ink formulations suitable for perovskite production. The subsequent component, a printing bot, applies these prepared inks in a grid pattern onto a single substrate.

RoboMapper possesses the remarkable capability to precisely deposit these minuscule samples of potential perovskite inks onto a single chip – an achievement unattainable by a mere human researcher. However, researchers can leverage RoboMapper's digital dexterity to simultaneously test hundreds of different inks using various diagnostic tools.

Aram Amassian and his team assessed the robot's proficiency in applying ink using a specific array of potential perovskite compounds. They employed RoboMapper to combine three ingredients in numerous proportions, subsequently printing the resulting mixtures and subjecting them to tests evaluating their structure, bandgap, and stability when exposed to light. Ultimately, the team identified a promising perovskite blend exhibiting the "ideal" properties for integration with silicon in solar cells.

Although the NCSU team evaluated RoboMapper's application for perovskite compounds, they did not combine them with silicon to assess the performance of these new solar "tandem" cells. Nevertheless, their designated "materials acceleration platform" (MAP) could also prove valuable for testing various other types of materials in ink form. The RoboMapper testing process is even more energy-efficient than computer simulations, the researchers noted, and has the potential to generate more authentic "real-world" data, which is crucial for training machine learning models while avoiding potential feedback loop degradation.