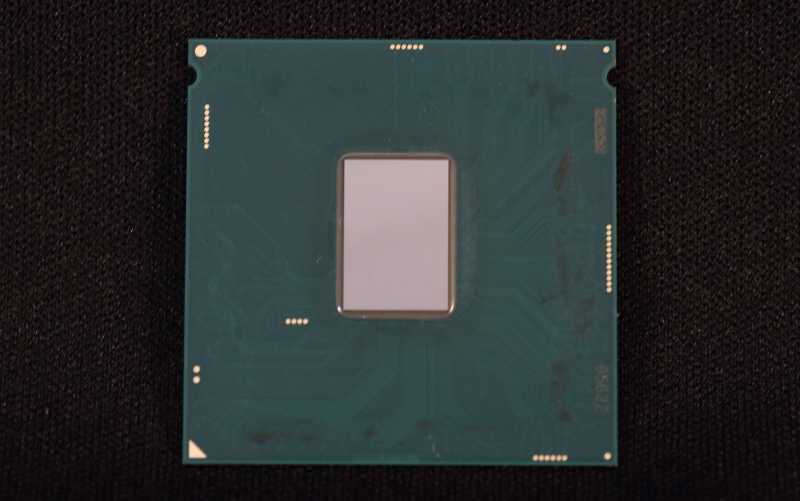

When you look at an Intel CPU straight out of its packaging, you'll see a large piece of metal sitting on top of a piece of silicon. That piece of metal isn't actually the CPU itself, rather a heat spreader that provides better contact between the die and the heatsink.

When you remove the heat spreader in a process known as 'delidding', you expose the CPU die underneath. As you can see on PC Watch's photo above, Intel's flagship 'Skylake' CPU, the Core i7-6700K, doesn't occupy much physical space on the processor's PCB; in fact it's smaller than most of Intel's previous CPUs such as Haswell, Ivy Bridge and even Broadwell.

The reason why the Core i7-6700K is so small is that it's built using a 14nm manufacturing process, which allows Intel to cram the same amount of transistors as previous generation 22nm chips into a smaller physical area. Skylake features fewer GPU execution units than Broadwell, which is also built using a 14nm process, making its die smaller in comparison.

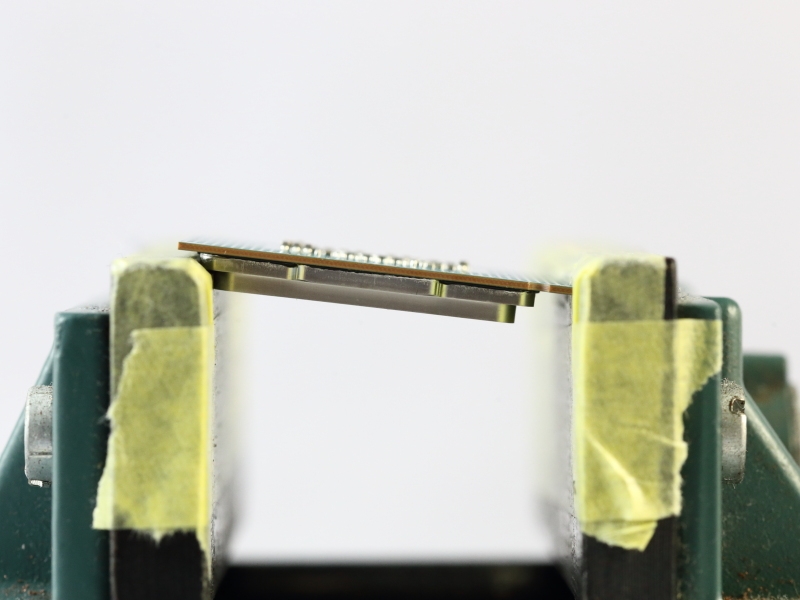

PC Watch decided to delid the i7-6700K to test the thermal interface material (TIM) Intel uses between the heat spreader and the die. The TIM is something Intel improved in the 'Devil's Canyon' Core i7-4790K after feedback from enthusiasts, but it appears as though a different material has been used for Intel's Skylake CPUs.

When replacing the stock TIM with two aftermarket solutions - Prolimatech PK-3 and Coollaboratory Liquid Pro - PC Watch noted temperature improvements at stock clock speeds and while overclocked. The Liquid Pro's liquid metal alloy was especially effective, dropping temperatures by 20°C while overclocked.

Although better thermal performance was achieved by switching out the TIM underneath Skylake's heat spreader, delidding a CPU isn't a simple process and if not enough care is taken it could damage the CPU permanently. But if you're an enthusiast and want to give it a try, it is possible to lower your CPU temperatures by replacing what sits between the heat spreader and CPU die.

Images courtesy of PC Watch