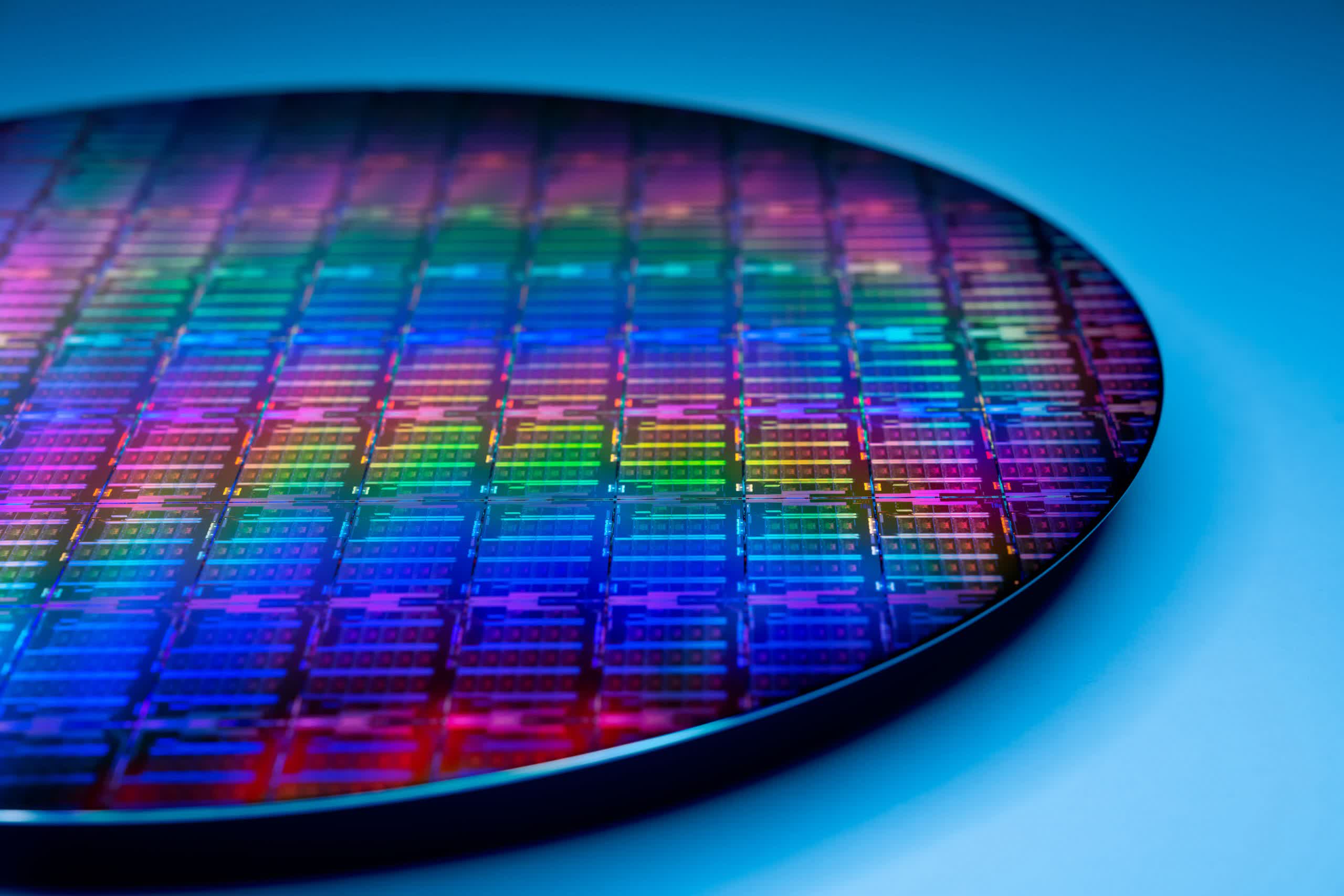

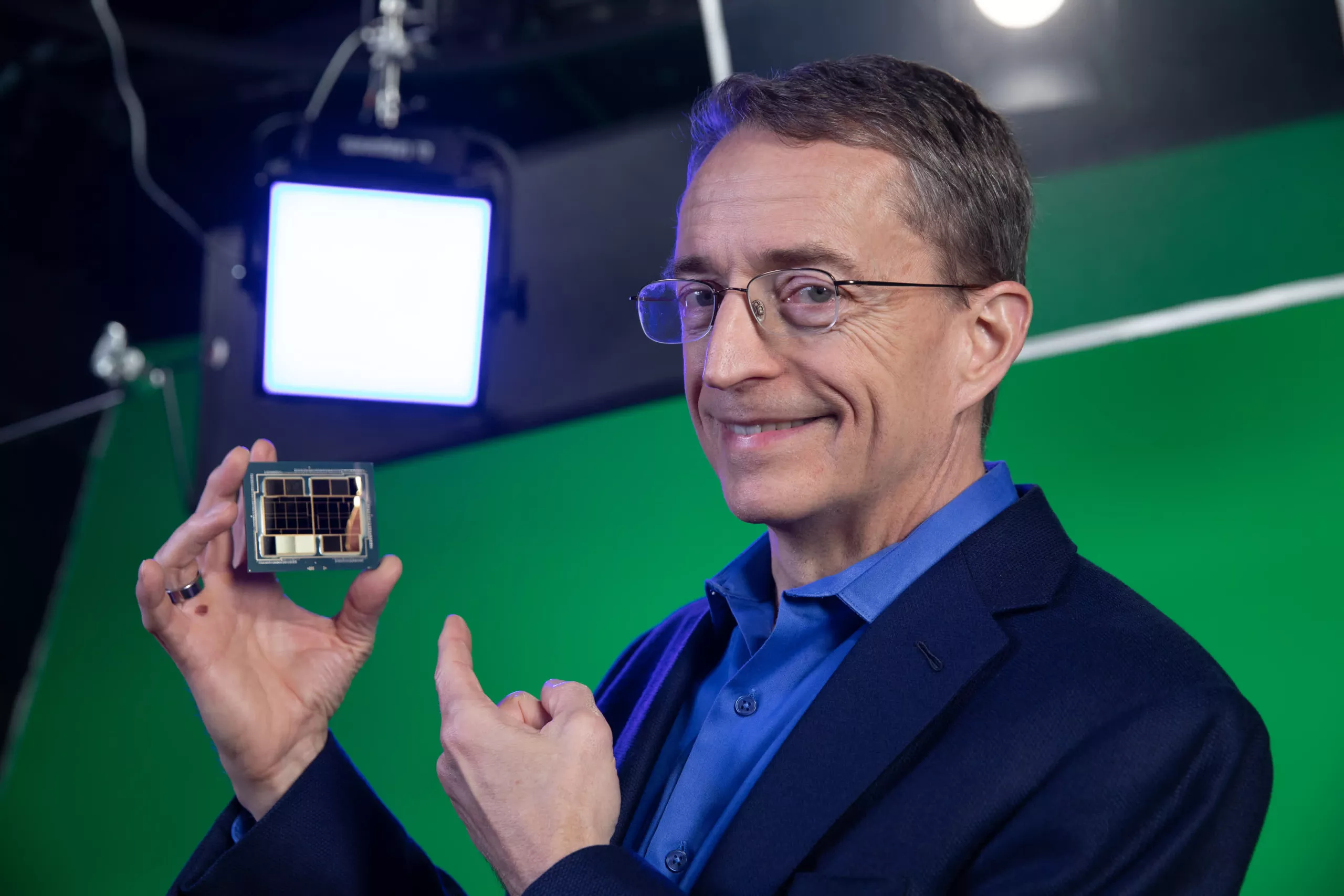

The big news this past week came in the form of Intel's announcement of its new strategy, doubling down on its fab and foundries. We wrote about it, but we want to expand on what we see as the defining challenge the company's initiative faces - how to deal with foundry customers. Put simply, Intel has set up a new division to serve as a Foundry, a manufacturing line for other company's designs. This has been a glaring hole in Intel's line-up for a long time. They have tried repeatedly to enter this business with no success.

Editor's Note:

Guest author Jonathan Goldberg is the founder of D2D Advisory, a multi-functional consulting firm. Jonathan has developed growth strategies and alliances for companies in the mobile, networking, gaming, and software industries.

There are some reasons to think this attempt may be more successful. Intel Foundry Services (IFS) is an entirely separate organization, reporting directly to the CEO. Despite its recent stumbles, Intel still has immense internal talent. It also has advanced packaging capabilities, which we neglected to mention, but could be very important. And crucially, they have a clear path for fixing their manufacturing process.

At its heart, Intel has always been a manufacturing powerhouse. In recent years, they lost their way. And in his remarks their CEO pointed to their own actions, ignoring the advice of their key supplier ASML, for their current position. All signs are that Intel should be able to catch up.

But a key piece of this strategy will be getting Foundry Services (IFS) to work. Without this, it will be hard for Intel to keep its fabs fully utilized and thus profitable. To do this, Intel has to solve its cultural problems and lack of customer service capabilities. We discussed this in depth, but we want to explore a key part of this here.

We have worked with all the major foundries over the years, and plenty of the smaller ones. When we get asked "how do you choose a fab?", we have a two part-answer.

First and foremost is manufacturing process, this dictates all other choices. But then how to choose between two foundries at the same process node - say TSMC versus Samsung at 7nm? The answer is not price, which for some reason everyone expects to be the answer in the world's most complex technological field.

Customer service seems like a really squishy criteria for the world's most complex technological fields, but it matters tremendously.

Instead the answer is customer service - how easy is it to work with the foundry. (If you want to know how TSMC vs Samsung shakes up on this scale, contact us for an offline discussion.)

Customer service seems like a really squishy criteria for the world's most complex technological fields, but it matters tremendously. And the heart of customer service is providing customers with all the things they need to build a chip profitably. This means giving customers access to assets like software tools and libraries and making sure customers have access to the best the foundry offers. Will Intel do this? Can they do this?

The answer is far from clear. First, there are the cultural issues. A lot of these intangible assets have been treated as the company's crown jewels - deliberately made hard for others to access. How is Intel going to decide what to share? And mechanically, how are they going to share them?

TSMC, for instance, has spent decades working with companies like Cadence and Synopsis to make the transition from chip design to chip manufacturing as frictionless as possible. There are some very real logistical challenges for Intel on this front. Keep in mind that today Intel fabs most chips from the companies it has acquired at other foundries. So even sharing internally is not really happening.

But more importantly how will the company decide how to allocate fab capacity? We wonder how will Intel prioritize its own products versus those of customers? Will they set up some sort of internal accounting system where Intel's CPU products have to bid against external companies? In practice, these kinds of things rarely work well (except for Amazon). This is theoretically how Samsung works, but not really in practice.

And this is not a small question. Foundry capacity often gets booked up months if not a year in advance. With Intel's CPU products bleeding market share, they will bring immense pressure to bear on getting their products to the head of the queue. And remember, Intel's entire product strategy is built around very tight integration with manufacturing, so it is almost a certainty that the company will see some form of margin hit from this process, and not just one-time restructuring charges, but a systemic transition in gross margin cost structures.

Ultimately, the answer will rest with customers. Which raises the very interesting question of who exactly will sign up to be an IFS customer? We speculate that Apple is a likely candidate. As much as Apple is now producing a CPU competitive to Intel's CPU, Apple is not really an Intel competitor. Apple has lost a lot of faith in Intel in recent years, but they will base their decision on Intel's capabilities. So there is a decent likelihood that if Intel can get back on track Apple would sign up.

But who else? We can rule out a few companies - notably AMD and probably Nvidia.

These companies are direct competitors with Intel's core CPU and GPU products (as much as Intel competes in GPUs). A while ago on Twitter, we speculated that Qualcomm could be a candidate. They don't really compete directly today. That may change as both companies have competing ambitions in an automotive market that is still years away. However, there is a big reason why Qualcomm and many others may want to sign up with Intel - let's call that reason 'patriotism'. Intel made a big deal about the US' reliance on a semi supply chain all based within missile range of China. It is no secret that Intel has been lobbying the US government hard for subsidies. So many companies may sign up for IFS to wave the flag. This may also persuade companies like Broadcom and Marvell to sign up.

The other big pool of customers are all those Internet companies building their own chips. The hyper-scalers all have good reasons to consider going with Intel. For one, as disruptive as they may be, they are not the biggest buyers of foundry capacity. They buy a lot of chips, but none yet rank in the top ten of TSMC customers. If IFS does it right, they are going to be very aggressive in pulling out all stops to court these customers.

For Intel, their value rests in the volume they bring as much as the optics of having a press release from such prominent companies. This is tricky because Amazon, for one, now has a competitive line of Arm-based CPUs. Would they want to fab those at Intel whose chips they are displacing? The same goes for Google who makes their own AI accelerators which compete against those made by some of Intel's recent acquisitions. And what about the Chinese cloud service providers Ali, Tencent and Baidu? They might be intrigued by Intel's courting, but here the patriotism argument works in reverse. Do any of them want their name attached to saving America's fab capabilities? On balance, we think some of these companies will at least be willing to send some volume Intel's way, which collectively may be enough to move the needle.

We think this leaves us in the realm of IFS is possibly viable. If Intel can sort out its manufacturing process, and if it can find the funds it needs (see above re:US government), and if it can build up a true customer service capability, and do all if that in under three years, then IFS should work.

Masthead credit: Nguyen Dang Hoang Nhu

https://www.techspot.com/news/89135-intel-20-customer-dilemma-foundry-move.html