A decline in personal computer sales has forced Intel to postpone the opening of a large chip manufacturing plant in Chandler, Arizona. Fab 42, deemed as a $5 billion project late last year, will remain unused for the foreseeable.

The Arizona Republic was the first to report the development which has since been confirmed by Intel spokesperson Chuck Mulloy via Reuters. In a statement on the matter, Mulloy said the newer fab has not been equipped with the capital equipment. Specifically, it has heating and air but it lacks the actual tools to build chips – or as he noted, the “expensive stuff.”

Mulloy said the new construction will remain vacant for now and will be targeted at future technologies although no timetable for a grand opening was mentioned. In the end, it all boils down to better capital utilization, he concluded.

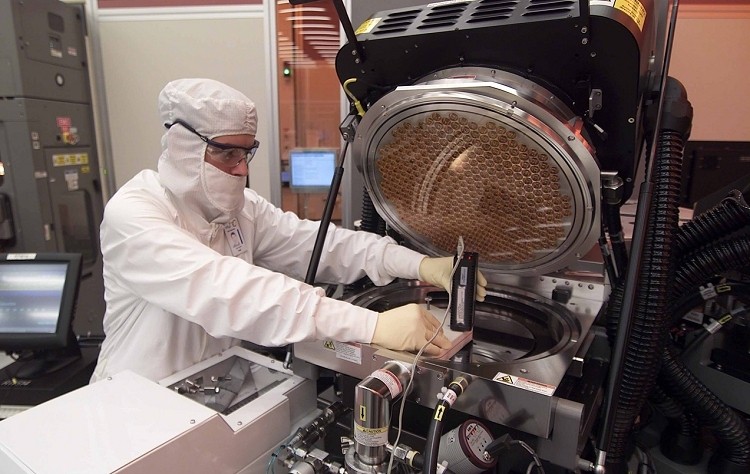

In the meantime, other factories on the same site are being upgraded to produce Intel’s more advanced chips. At present, those facilities build chips on the 22-nanometer manufacturing process. The initial plan was to use the new fab to built 14-nanometer parts but that equipment will now be installed in the other facilities.

Elsewhere, the company is also working to expand a plant in Oregon that will be used to make larger chip wafers. The largest wafers used in the chip industry now measure 300 millimeters across but the Oregon plant will be capable of wafers measuring 450 millimeters.