Why it matters: Changes are coming to Intel, and I’m not simply referring to new management. According to the latest research from a leading market intelligence firm, Intel will start outsourcing production of some of its CPUs to TSMC later this year.

According to market intelligence firm TrendForce, Intel is planning to outsource production of its Core i3 CPUs to Taiwan Semiconductor Manufacturing Company (TSMC) in the second half of 2021 using its 5nm node. Chipzilla’s mid-range and high-end CPUs, meanwhile, are expected to enter mass production on TSMC’s 3nm node in the second half of 2022.

TrendForce’s latest investigation jives with what we heard as recently as last week with regard to Intel talking with TSMC about outsourcing some of its chip production.

According to Bloomberg’s report from last Friday, any chips that Intel sources from TSMC wouldn’t be ready for the market until 2023 at the earliest.

Back in July, Intel CEO Bob Swan said Intel would consider outsourcing some of its CPU manufacturing. At last check, the plan was for Swan to reveal Intel’s intentions during its upcoming earnings report on January 21. Earlier today, however, the company announced that Swan will be stepping down in mid-February, so it’s anyone’s guess as to whether or not the January 21 date is still on.

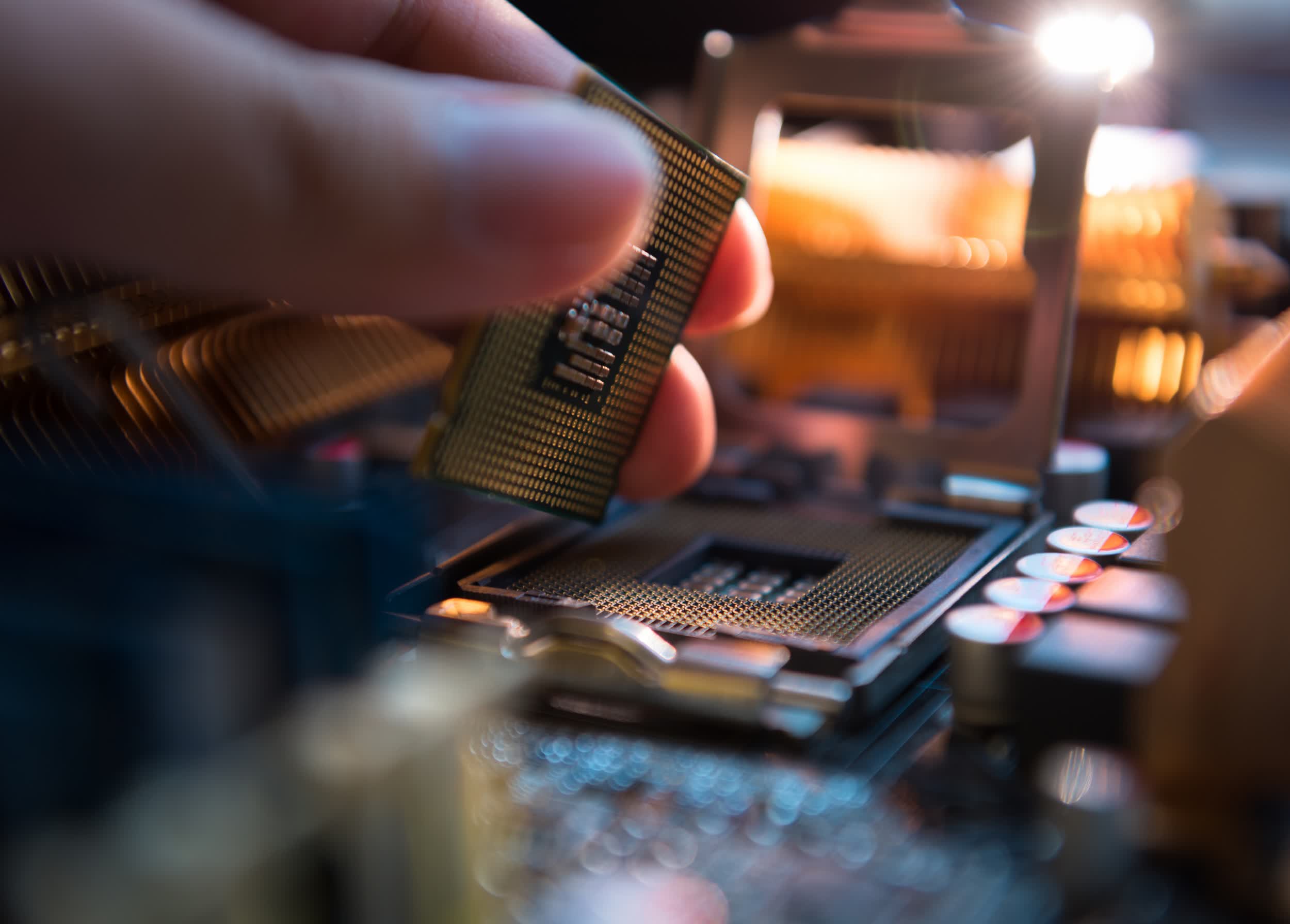

Image credit Sundry Photography, Pawarun Chitchirachan

https://www.techspot.com/news/88281-intel-reportedly-start-shifting-cpu-production-tsmc-later.html