In brief: When it comes to liquid cooling a PC, details matter. The basics have long since been agreed upon – a water block, a pump, perhaps a reservoir, a radiator, and tubing that links it all together. With so many individual components in play, it should come as little surprise that there's plenty of room for optimization.

A key component in a traditional liquid cooling loop is the water block. Often comprised of copper, a standard block is designed to take in liquid, pass it over an array of fins to absorb heat, and expel the heated liquid through the outlet. The fin array is designed to maximize surface area while also maintaining good fluid flow, and this is where technology and science come into play.

PCWorld recently sat down with Dr. Ian Cutress to discuss a new approach that could change the liquid cooling game. A startup named Fabric8 Labs is using math to calculate the best possible mix of surface area and liquid flow, and leveraging a technology called Electrochemical Additive Manufacturing, or ECAM, to bring it to life. Think of ECAM as 3D printing, but for metals.

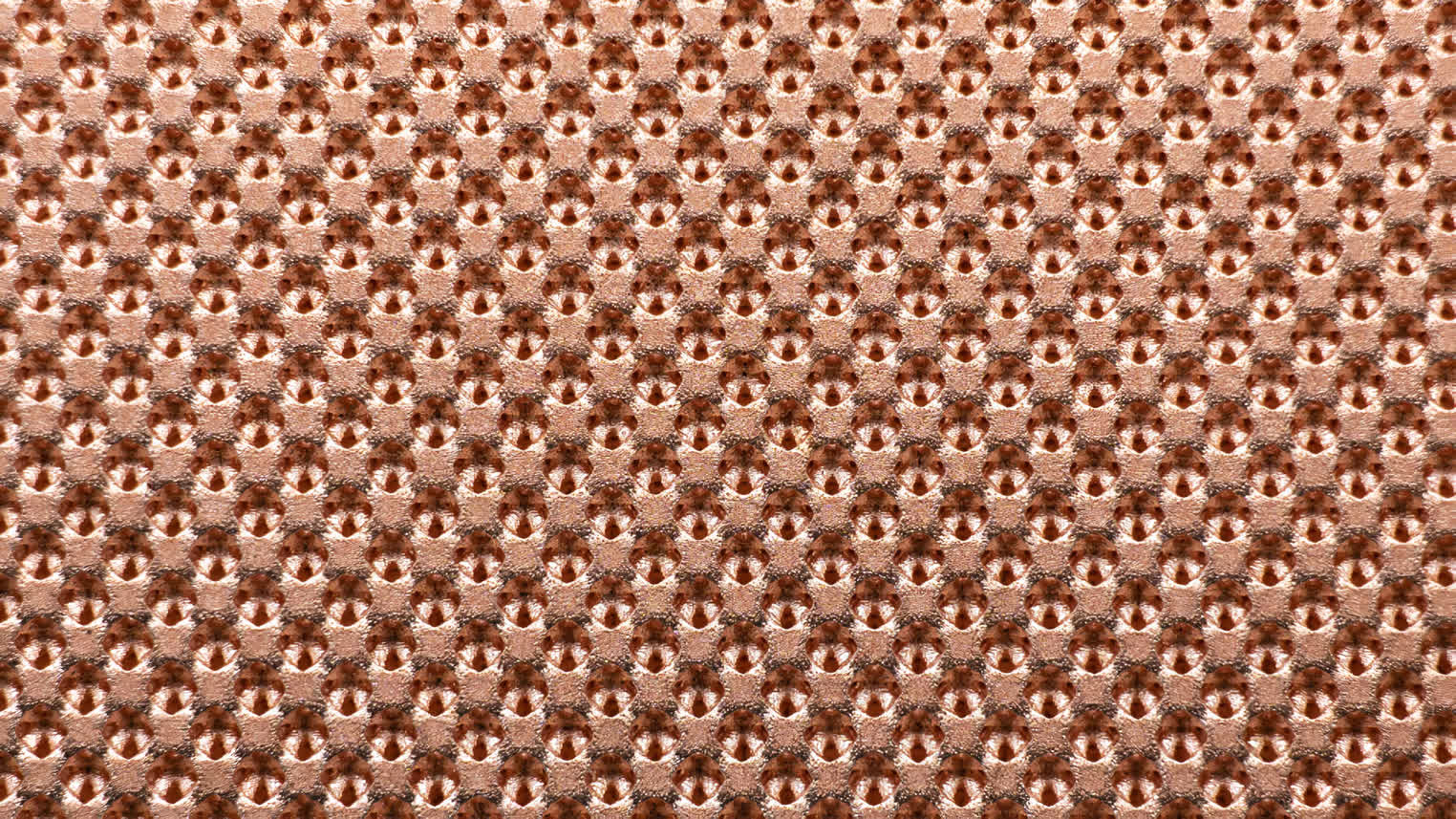

The design they came up with looks a bit unconventional – Cutress described it as looking like twisted Swiss cheese – but it's apparently better than traditional fin arrays in multiple categories. Not only does it afford better cooling performance, it also requires less pumping power and is more affordable to manufacture than standard copper finned blocks. These attributes make it highly attractive, especially in environments like data centers where even a small change can scale to make a sizable overall impact.

Some modern CPUs also have hotspots – sections of the chip that are hotter than others based on the layout of cores and whatnot. With ECAM, one could theoretically design a block to focus on known hotspot regions of a particular CPU.

So, when can you get your hands on one of these fancy new water blocks? According to Cutress, it could be a while considering the liquid cooling market already has a handful of established players and it's not exactly a high margin industry. Perhaps the most viable route to commercial availability would be a licensing deal with an existing manufacturer. Either way, we'll keep an eye on it and report back with any developments.