Why it matters: Technology has permeated into every aspect of human life, but lockdown measures could have immeasureable consequences on the companies that piece it together using complex global supply chains. That's why chipmakers are asking the government to come up with solutions to prevent their factories from grinding to a halt.

The coronavirus pandemic has already left its mark on almost every industry and is testing the limits of the medical systems in countries from Europe, and, given the current rate of newly confirmed cases of infection, the US.

Tech companies have also been hit by the crisis, and an industry association representing the largest US semiconductor companies is currently working with federal officials that have ordered lockdowns to convince them to allow their continued operation.

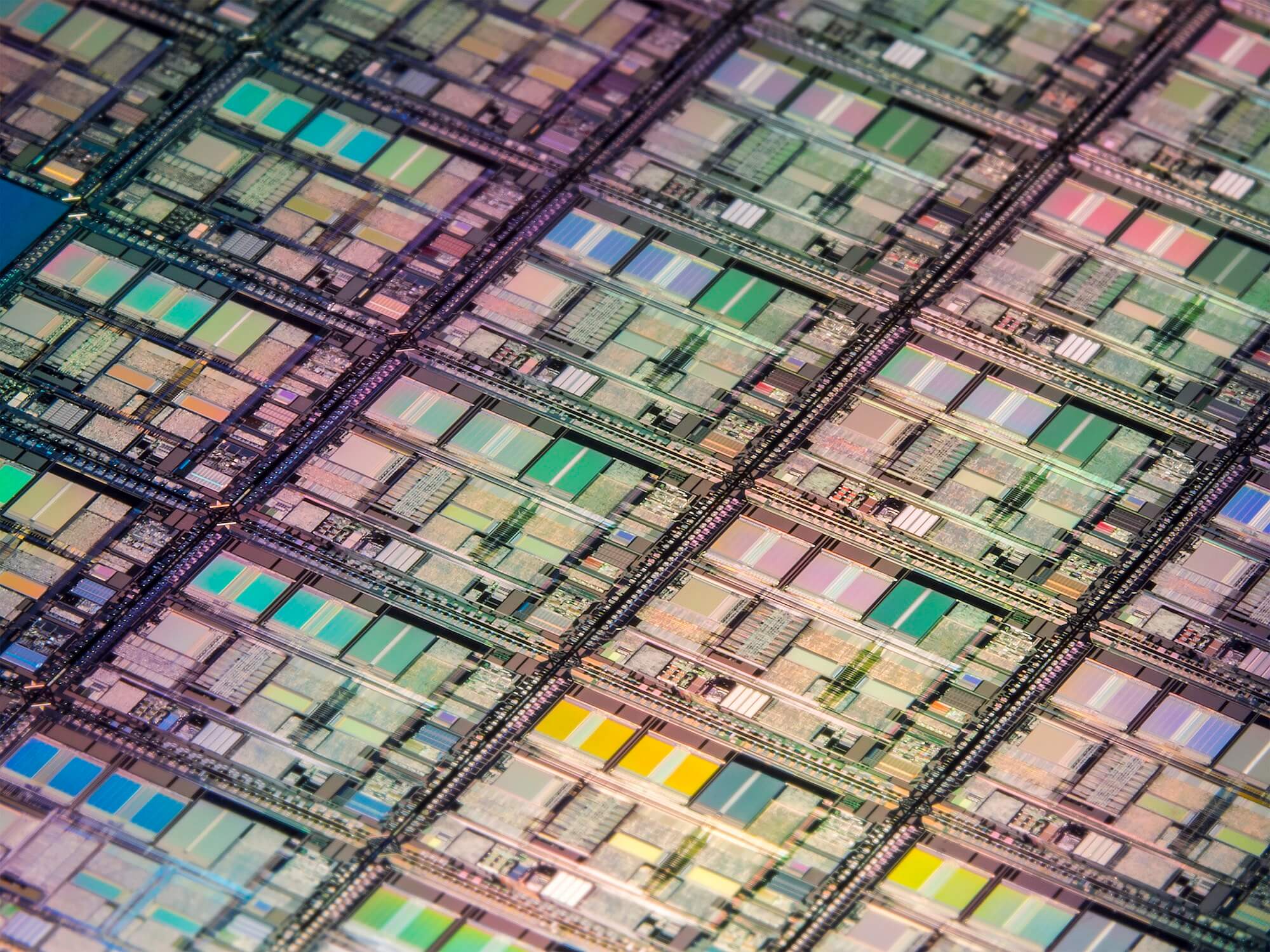

In its public letter, the Semiconductor Industry Association argues that chipmakers with local factories such as Micron and Intel are essential in producing the technology that helps fight the virus by powering computers and data centers that make it possible for millions of professionals to work from home and communicate with others. Not only that, but every piece of medical equipment, power grids, transportation systems, education, and pretty much every human activity nowadays makes use of technology on some level.

SIA president John Neuffer says Homeland Security should refine guidance sent to state officials to prevent any manufacturing disruptions. He notes that "ensuring the continuity of semiconductor and related supply chains is necessary to support the even greater range of services that will be digitized in the coming weeks and months."

There is a strong case to be made that cleanroom operations in the semiconductor industry are highly automated and take place in large areas where people are usually working at a distance from each other and filtration systems keep out airborne particulates that are 0.1 micrometer in size (for reference, Covid-19 is 0.125 micrometers).

Their work is also subject to strict protocols to prevent contaminants, from the moment they enter the facility through an airlock wearing full protective clothing and masks, and throughout their work day. This has been demonstrated by South Korea and China where semiconductor manufacturing has been operating successfully by following stricter safety protocols, which is why Samsung was able to deliver one million DDR4 DRAM modules using EUV lithography.