In brief: Most consumers are oblivious to the herculean efforts that go into hardware production. Robots and humans must work in perfect harmony to get the job done on time while minimizing mistakes. If you've never seen a production line in action, it's quite fascinating.

It's easy to become jaded when a hobby becomes your livelihood. You just kind of expect the next best thing to show up without much consideration or appreciation for what goes into the R&D and manufacturing process.

That's where I am with computer hardware and I suspect many of you may also be in the same boat.

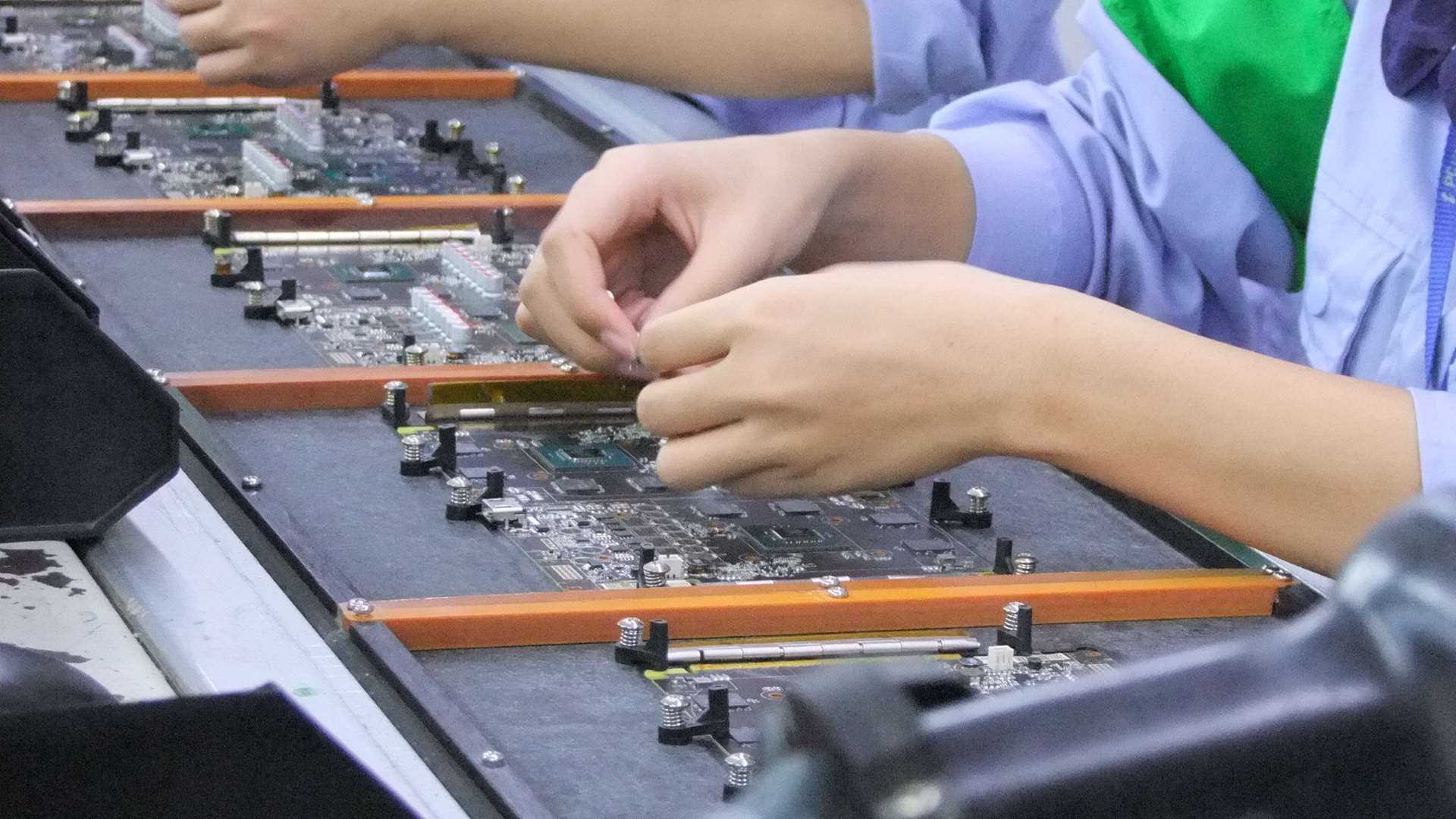

One potential way to develop a newfound appreciation for hardware is to pull back the curtain and see how the magic is made. Fortunately for us, journalists from Impress Watch and PCGamesN brought along their cameras during a recent tour of PC Partner's factory in China.

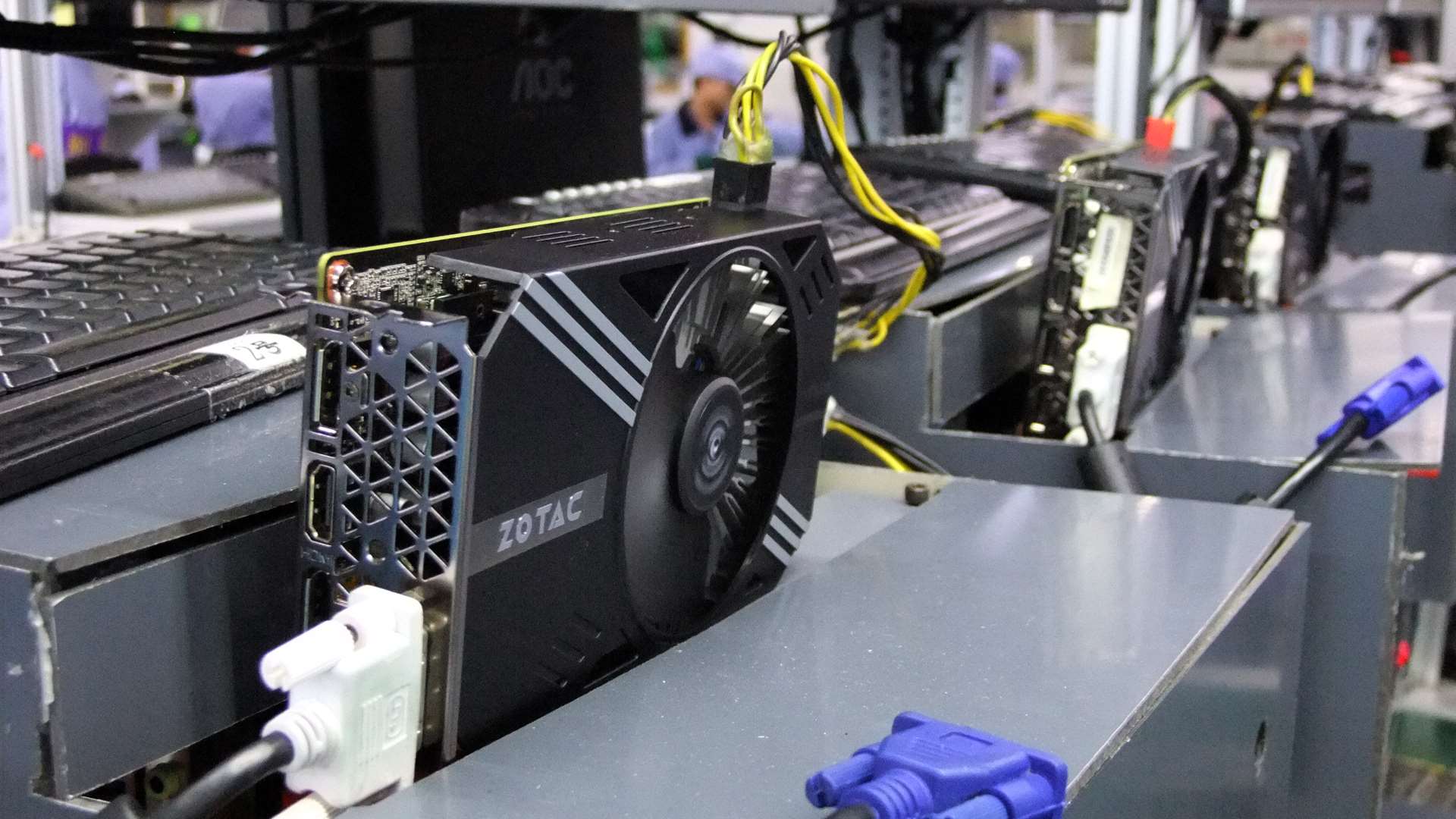

PC Partner is a massive contract manufacturer that makes hardware for companies like Dell, AMD, Samsung, Acer, Sapphire, LG, Inno3D and Zotac. The publications' tour focuses specifically on Zotac video cards, showcasing the massive amount of human labor and robotic help that goes into the creation of a graphics accelerator.

PCGamesN has a lengthy write-up on its tour complete with photos while Impress Watch opted for a nearly nine-minute-long video with Japanese subtitles.

Perhaps most impressive is the fact that PC Partner's operations are so streamlined, they can switch manufacturing from one card to another in as little as five to 15 minutes. In manufacturing where time is money, every second counts.

Images courtesy PCGamesN