What just happened? On Thursday, Taiwan's state-run Xingda power plant experienced a failure that affected a large portion of the island's residents and businesses. It caused power decreases and grid failures across the nation and hit several regions that are home to Taiwan's semiconductor manufacturers. TSMC is currently assessing the impact after observing voltage drops lasting between 400ms and 1000ms at some locations.

The Xingda plant, run by Taipower, supplies an estimated one-seventh of Taiwan's total electrical output. The outage lasted 90 minutes and affected an estimated five million households. The cause of the incident was attributed to a failure in the station's turbine room, which triggered an emergency shutdown to avoid further damage. It resulted in cascading blackouts across the island and a 10.5MW drop in total power supply.

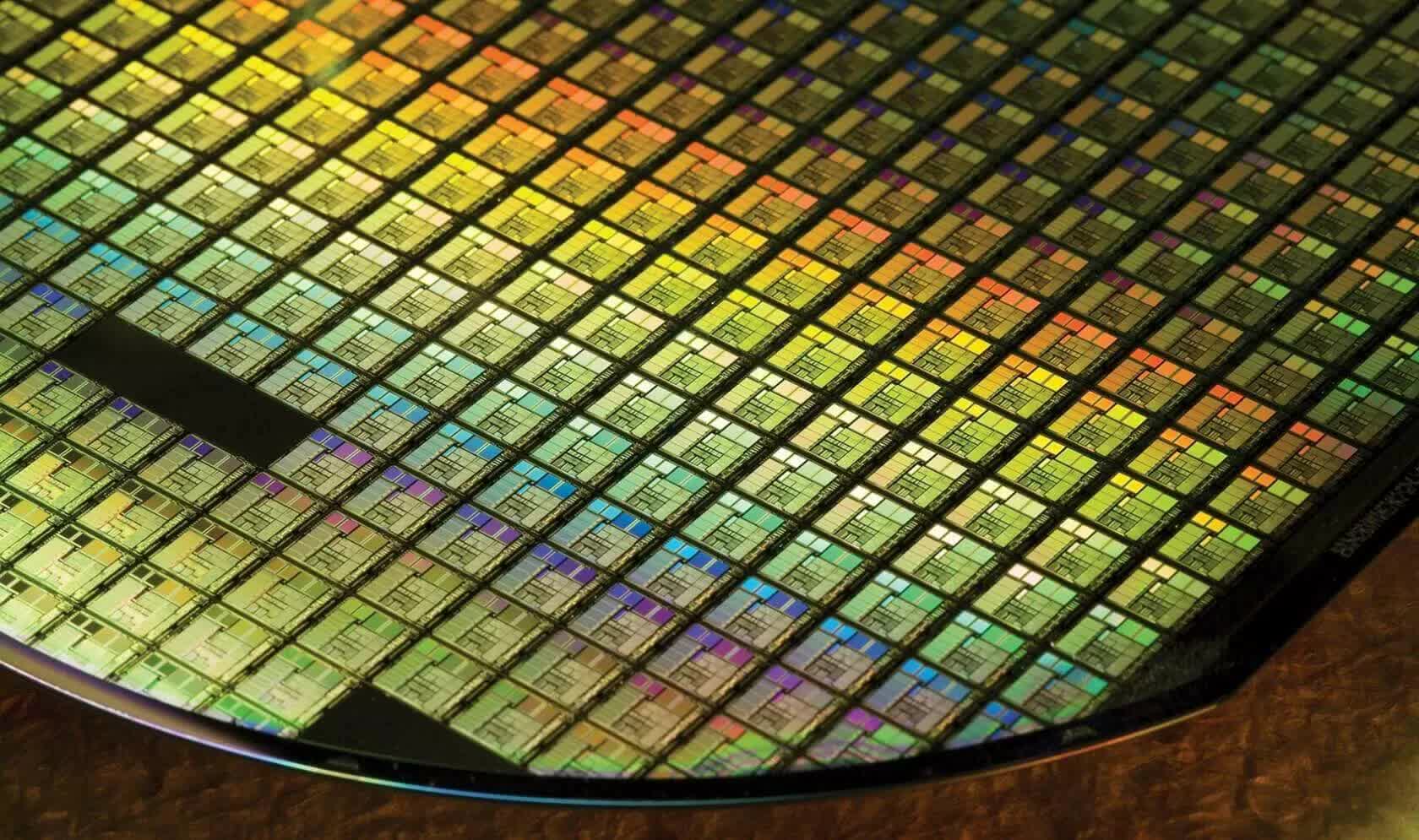

Several of Taiwan's semiconductor manufacturers were affected and continue to assess the situation. The most notable companies affected were the well-known Taiwan Semiconductor Manufacturing Company (TSMC) and Innolux, which is currently Taiwan's largest display panel manufacturer. According to UMC, another semiconductor manufacturer in the region, there was a manageable impact on their UMC Nanke plant.

TSMC's initial assessment states that any production problems resulting from these power fluctuations should be negligible. However, the overall effect of the 90-minute incident is still being assessed. Innolux is also continuing to assess the impact to their production operations, and as of Friday, the company's facilities were still running on backup generators.

Despite TSMC's claims of little to no impact, the delays stemming from the 90-minute incident could cascade down and ultimately extend the already hobbled semiconductor industry's chip shortage. For decades, semiconductor manufacturers have relied on lean manufacturing, a manufacturing methodology that focuses on providing customers with what they need when they need it. That means low to no additional inventory or surplus and almost no room for error during manufacturing and delivery. Any delays in this type of environment can result in missed or delayed shipments, affecting both TSMC's upcoming deadlines as well as deadlines for customers that rely on those nodes for their own products.

Let's hope TSMC stays on track and helps to put this whole shortage behind us.