In brief: The demand for batteries for electric cars and grid storage is expected to reach 4,584 gigawatt hours by 2040, which is why a lot of startups are trying to figure out the best way to satisfy that demand. Silicon nanoparticles are a key new ingredient for improved battery capacities, and a New Orleans startup wants to help battery makers by producing it at scale using conventional manufacturing techniques.

It's easy to get excited every time there's news about a new battery technology that holds great potential to power our electric future. There's a lot of work going into making batteries charge faster, hold more energy, and even malleable enough to be stretched and twisted without losing its ability to power devices.

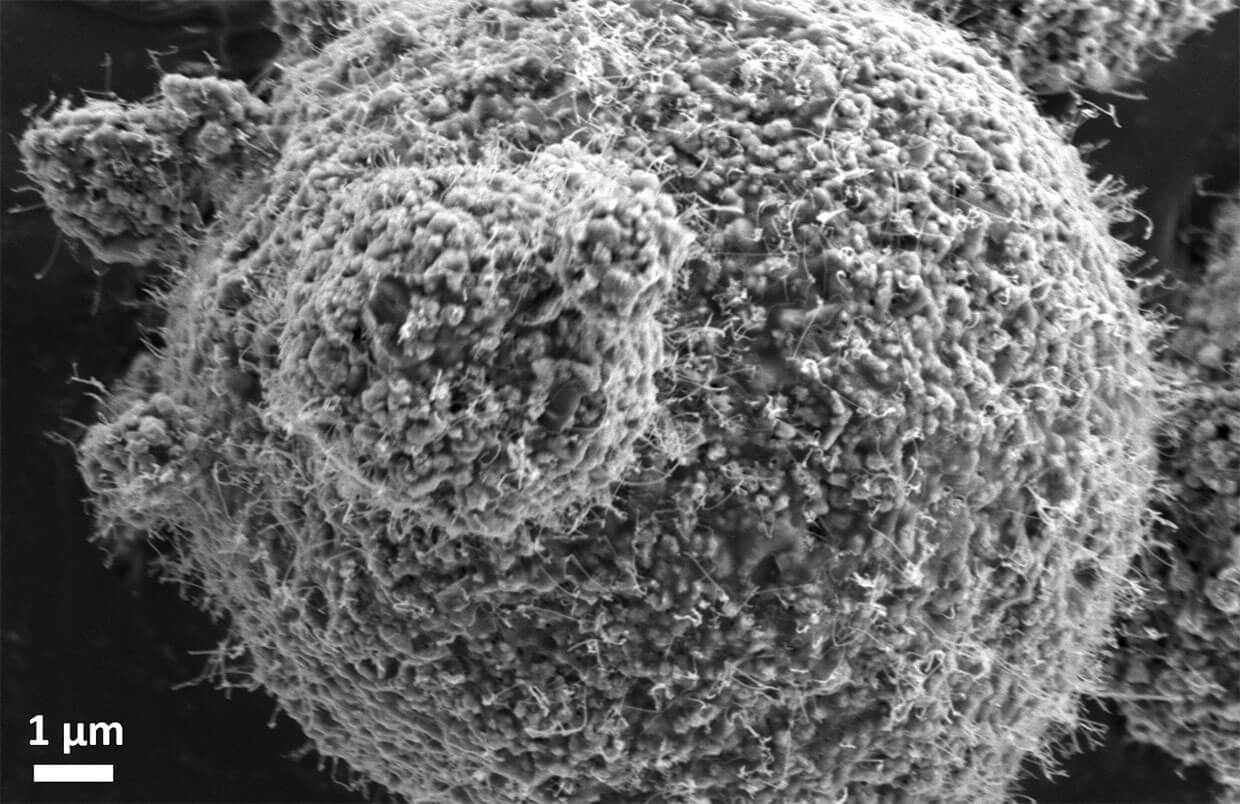

Of the many different approaches that have been explored to achieve greater capacity, silicon is the most promising as a replacement for graphite in anodes for lithium-ion batteries. But despite its abundance and ten times greater capacity, silicon "bloats" during charging by combining with lithium to form an alloy called lithium silicide that takes 3-4 times the initial volume.

This can greatly reduce the safety of a battery that uses a silicon anode, but several startups are looking for ways to work around this issue. Examples of ideas include caging silicon using graphene, or using a brush-like anode made of silicon nanowires that can safely expand in diameter. In any case, there's going to be huge demand for silicon nanoparticles in the coming decade.

Instead of trying to figure which approach is the best, a New Orleans-based startup called Advano wants to focus on achieving scale as quickly as possible by taking a top-down approach. Whereas most companies start with a gas or a liquid to achieve the most fine-tuned silicon nanoparticles, Advano plans to just grind down the bulk material -- mostly repurposed silicon from solar panels -- until the resulting nanoparticles are good enough.

The company says it can currently produce a ton of silicon nanoparticles per year, and will soon start production at a new facility that could make ten times as much. That's still a relatively low amount, but the idea is that as Advano scales up this new process, battery manufacturers can incorporate varying amounts of silicon nanoparticles to improve capacity, which is precisely what Tesla is doing.

Advano says it's using conventional techniques that are normally used for graphite anodes, which makes it easier to tap into existing supply chains. That said, founder Alexander Girau is running a small company of just 20 employees, which he says has the ability to move faster.

Ultimately, the idea is to drive prices down from $500-10,000 per kg of silicon nanoparticles to something between $15-150 per kg.

A similar approach is used by XNRGI, a startup that uses the same manufacturing techniques as chipmakers to produce "porous silicon" batteries for pretty much every kind of application imaginable, including transportation, drones, power grid storage, and consumer electronics.

https://www.techspot.com/news/83239-new-orleans-startup-wants-scale-up-silicon-nanoparticle.html