Forward-looking: People have been building structures with 3D printing techniques for years, but one group of researchers wants to bring AI-driven construction to a new scale. If successful, it could construct a dam more quickly and cheaply than with human labor.

Researchers from Beijing's Tsinghua University recently unveiled plans to build an almost 600ft-tall dam using 3D printing methods. It could be the biggest 3D-printed, AI-built structure ever made, but that may also depend on the definition of "3D printing."

Builders have already saved time and money by constructing homes using large 3D printers to make concrete layers. Last year, a fabrication company used robotic wire-and-arc additive manufacturing to 3D print a metal bridge in the Netherlands. The Tsinghua University proposal, however, doesn't involve any such techniques.

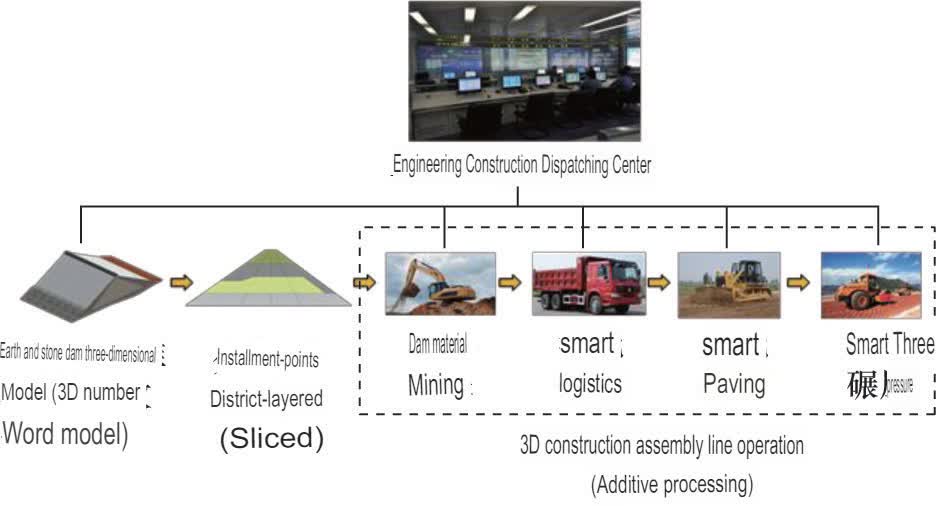

The researchers want to complete the currently-in-construction 590ft Yangqu hydropower plant on a Tibetan portion of the Yellow River using a legion of AI-driven robots, excavators, trucks, bulldozers, pavers, and other vehicles. Combined with an automated scheduling system, the researchers refer to the system as a single massive 3D printer.

Machine translation from Chinese

No humans would be directly involved in building the dam. An AI would slice a 3D model of the project into layers, then assign each layer to the unmanned machines sequentially. The AI would automatically plan material collection, driving routes, and placement. It can also analyze vibrations to determine build quality. Humans would only mine the fill rocks.

Aside from advantages in speed and cost, the machines could better withstand hazards like low oxygen levels, work around the clock, and researchers think they are less prone to human mistakes. The most apparent drawback is the potential loss of jobs that would normally come from such a massive project.

The dam is slated for completion in 2024 and will deliver almost 5 billion kilowatt hours of electricity to Henan province.

The Chinese government very well could sign off on the proposal given the success of another large 3D printing construction project in Shanghai last year. The Wisdom Bay bridge is an almost 30-foot-long Bluetooth-operated bridge that can unfold in under a minute.

Image Credit: Weibo

https://www.techspot.com/news/95802-researchers-want-build-dam-distributed-3d-printer.html