Rumor mill: As semiconductor mass production starts to enter the 3nm era, all of the major competitors are intensifying the race toward 2nm. While companies like Samsung and Intel look ahead to ever-smaller process nodes, industry leader TSMC is taking preliminary steps to stay ahead.

Sources have told Taiwan outlet Economic Daily that TSMC has started pre-production work on 2nm semiconductors, a crucial step toward trial production. The company's current timeline could keep it ahead of competitors like Intel and Samsung.

Reportedly, TSMC has sent engineers and support workers to the Baoshan, Taiwan Zhuke R&D plant to prepare for 2nm trial production, aiming to produce 1,000 wafers this year. The company declined to comment on the information. Previously confirmed roadmaps indicate plans for 2nm trial production in 2024, with mass production coming in 2025.

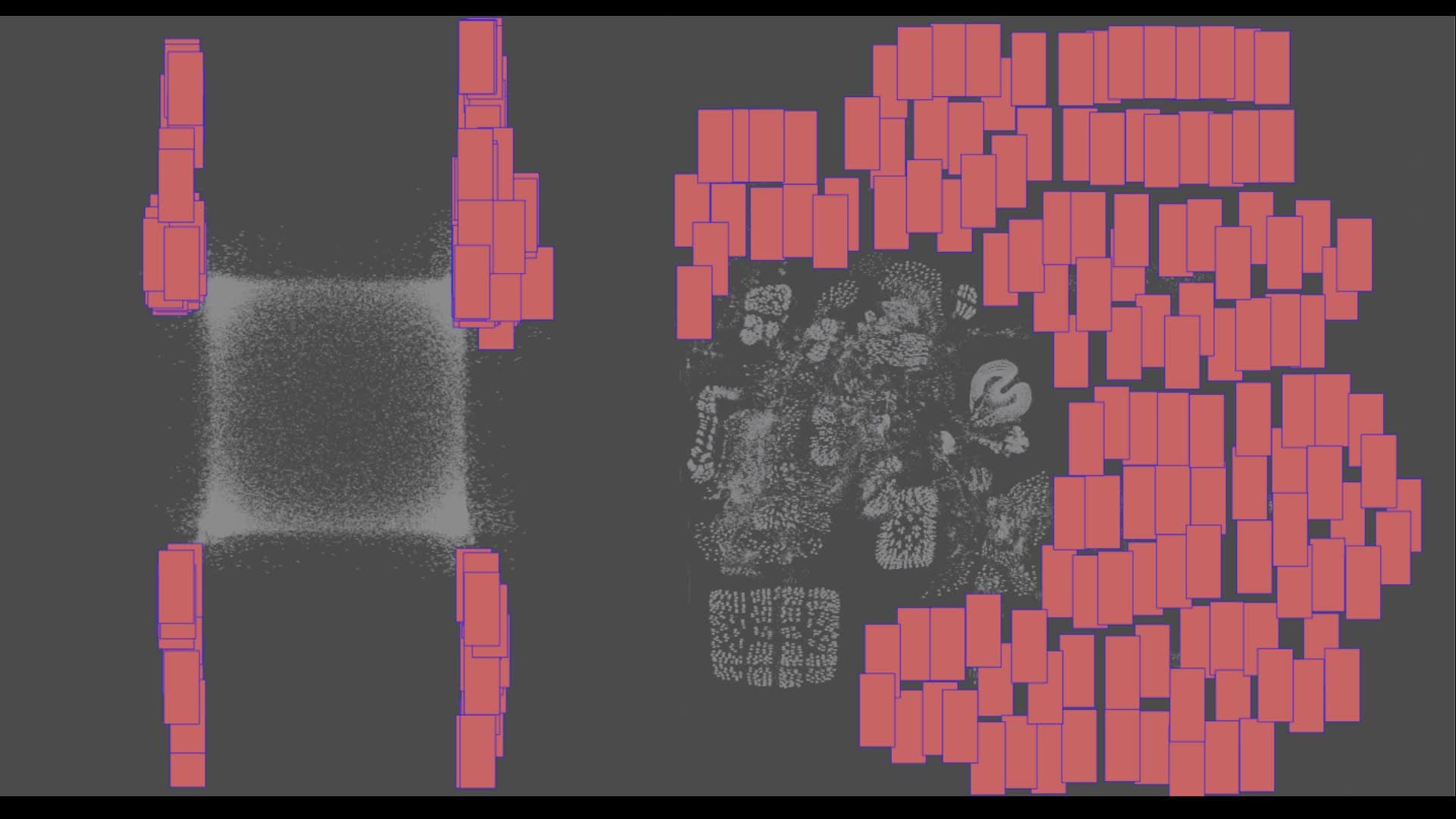

Interestingly, Economic Daily sources say TSMC's manufacturing process utilizes an AI-enhanced method called AutoDMP which is powered by Nvidia's DGX H100 chips. The AI optimizes chip designs 30 times faster than other techniques, improving energy efficiency and decreasing carbon emissions.

Nvidia's AutoDMP in action

With 2nm, TSMC will switch to gate-all-around (GAAFET) transistors, which can increase transistor density and shrink the leakage current. The new node could improve performance over 3nm by 10-15 percent at the same power level or use 20-25 percent less energy with the same performance.

Meanwhile, Intel wants to release its 20-Ångström (20A, essentially 2nm) node in 2024, with Samsung planning to start 2nm mass production in 2025. Both will use GAAFET and backside power delivery to increase logic density and decrease power leakage. Japanese company Rapidus aims to mass-produce 2nm semiconductors by 2027. Looking further ahead, Samsung intends to reach 1.4nm by 2027, while TSMC is making plans for 1nm.

In the near term, Samsung and TSMC are focused on improving their 3nm nodes. Samsung started on 3nm last June, while TSMC began mass production right before the new year.

However, Apple snapped up TSMC's entirely early supply of 3nm transistors, likely for upcoming products like the iPhone 15. This could enable Samsung to court other customers like Nvidia, Qualcomm, and Baidu for its forthcoming 3nm GAA node. Samsung, Intel, and TSMC plan to offer more efficient versions of 3nm in 2024.

https://www.techspot.com/news/98968-tsmc-prepares-2nm-trial-production-ai-assisted-process.html