Why it matters: A UK-based electronics manufacturer has developed what it is calling the world's first fully recyclable PCB substrate. Widespread adoption could revolutionize the e-waste industry, and at least one major player has already signed up to participate.

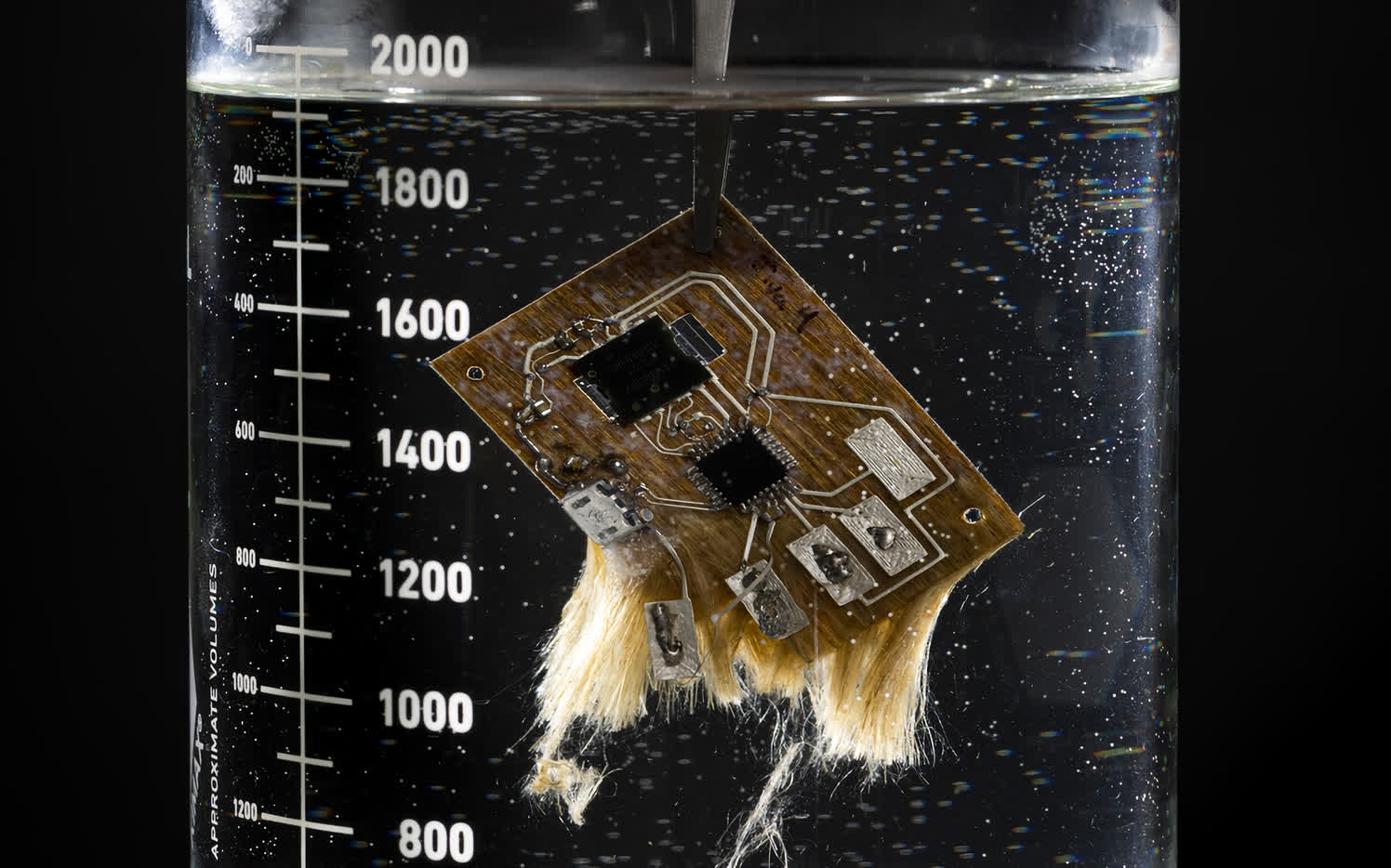

Infineon recently announced it will be adopting Jiva Materials' Soluboard, a biodegradable printed circuit board constructed of natural plant-based fibers. Instead of shredding and burning the PCB once it has been discarded, recyclers can submerge it in hot water (90 C / 194 F) for half an hour. The hot bath causes the PCB fibers to disintegrate, leaving behind solid chips and other components that can easily be recovered and reused or sent downstream for further recycling.

Should a Soluboard slip through the cracks and end up with other electronics, it will burn just the same as regular PCBs, the company said.

â»ï¸Â We are adopting Soluboard®, a #recyclable & #biodegradable printed circuit board substrate based on natural fibers. It was designed by @JivaMaterials & the #organic structure allows the components of devices to dissolve when immersed in hot water. More: https://t.co/3yLMC5cuGh pic.twitter.com/mnWjPbSok7

– Infineon (@Infineon) July 28, 2023

The half-hour, high-temp soak should quell concerns regarding common spills like sodas onto smartphones or even quick dunks in the tub. Jiva also said it is engineering Soluboard to be resistant to high humidity environments.

Still, there's a negative emotion that comes with the idea of mixing liquids with electronics. Others have expressed concern that nefarious hardware makers could use the tech for planned obsolescence as a way to force consumers to upgrade to newer devices after a certain period of time.

Also see: Sustainable Computing, Explained

Last year, Microsoft used a Soluboard PCB to create a biodegradable computer mouse. As part of the testing process, the circuit board was dissolved in water. The main chip was recovered, baked in an oven to remove moisture and reused with no signs of performance loss. Microsoft concluded the design reduced the mouse's environmental carbon impact by 60.2 percent compared to a traditional mouse.

Interestingly enough, Microsoft said its circuit could be dissolved in just 5.5 minutes at 100 degrees Celsius or in five hours in 20 degree C water. That differs from the 90 degree C that Jiva Materials co-founder Jonathan Swanston mentioned to The Register, but perhaps Microsoft was using a composition with different characteristics.

https://www.techspot.com/news/99625-water-soluble-circuit-boards-promise-drastic-reduction-e.html