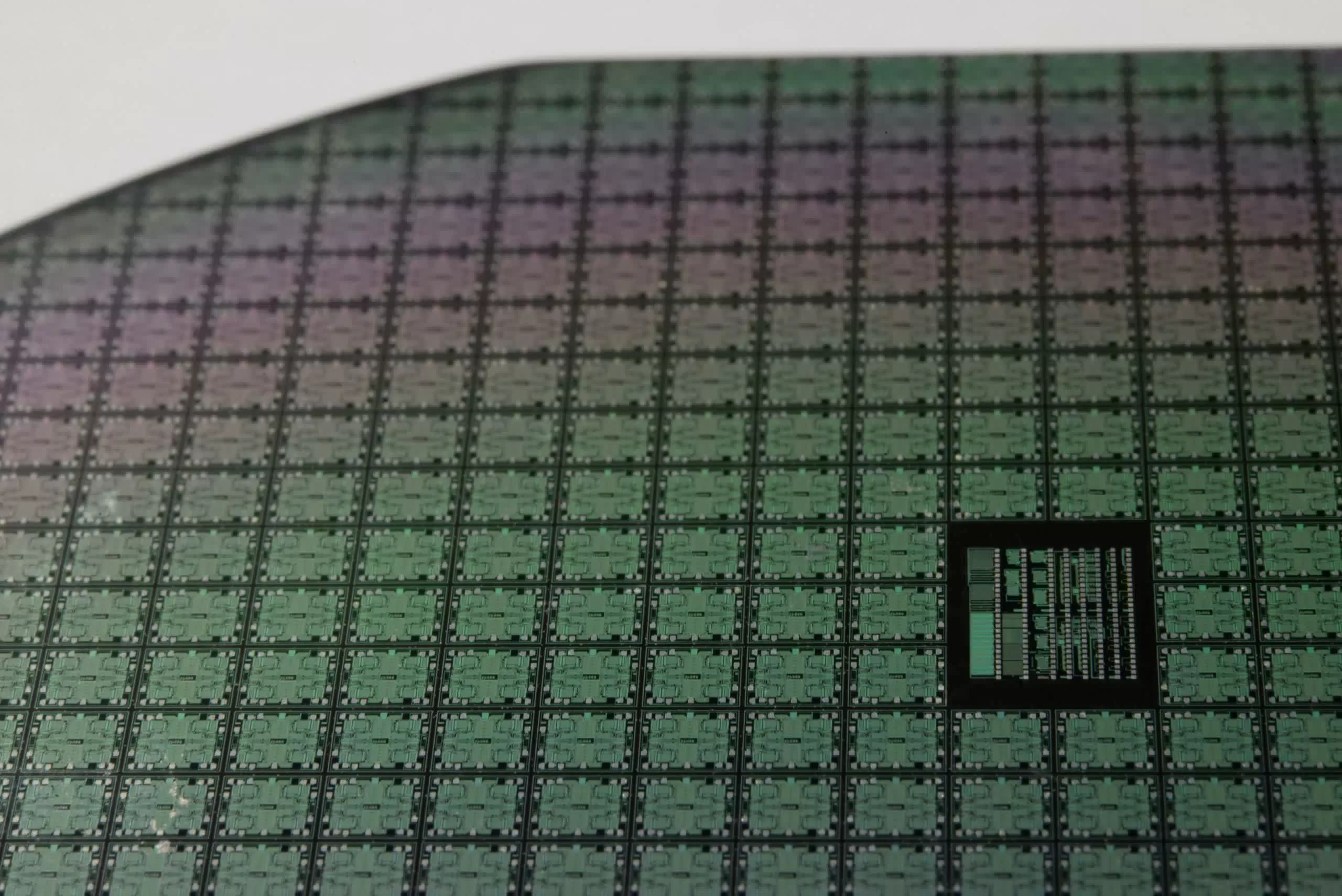

In brief: CSET (The Center for Security and Emerging Technologies) has published a new report, titled “AI chips: What they are and why they matter,” in which they calculate the sales price of silicon wafers. They found that TSMC’s 5nm node requires exceptionally expensive wafers that aren’t cheaper on a per-chip basis than 7nm chips. However, they still believe that 5nm chips are a popular purchase.

According to CSET’s model, a single 300 mm wafer built on the 5nm node costs approximately $16,988. A similar wafer built on the 7nm node reportedly costs $9,346.

Using a theoretical ~600 mm2 die, approximately equal in size to the Nvidia GA102 GPU used inside the RTX 3080 and RTX 3090, the per-chip costs of each die were calculated to be $233 and $238, for the 7nm and 5nm nodes, respectively.

CSET: Calculation of foundry sale price per chip in 2020 by node

| 16/12nm | 10nm | 7nm | 5nm | |

| Mass production year and quarter | 2015 Q3 | 2017 Q2 | 2018 Q3 | 2020 Q |

| Capital investment per wafer processed per year | $11,220 | $13,169 | $14,267 | $16,746 |

| Capital consumed per wafer processed in 2020 | $993 | $1,494 | $2,330 | $4,235 |

| Other costs and markup per wafer | $2,990 | $4,498 | $7,016 | $12,753 |

| Foundry sale price per wafer | $3,984 | $5,992 | $9,346 | $16,988 |

| Foundry sale price per chip | $331 | $274 | $233 | $238 |

Reproduced from CSET report "AI Chips: What Are They and Why They Matter"

The foundry sale price per wafer is calculated as the sum of the "other costs and mark-up per wafer" and the "capital consumed per wafer processed in 2020," or in other words, the sum of the profit margins, assembly cost, and estimated development cost. Consequently, this is an average value for only a small window of time; TSMC will be varying the actual sales price above and below this value depending on long-term strategies and market conditions.

Nevertheless, this is a rigorously estimated value and a good baseline for the actual sales price of the wafers. From it, we can deduce that 5nm products, including the processors used in the next generation of Apple handsets, will not be cheaper than existing products.

The high costs of 5nm production are largely a consequence of their novelty, and in time, they’ll become cheaper. However, the 5nm node does require some unique treatments that make it more expensive than older nodes. It is heavily reliant on EUV (extreme ultraviolet lithography) techniques, and reportedly, each EUV tool costs $120 million. A single wafer can have up to fourteen EUV layers applied to it.

Despite the cost, the 5nm node is a promising one. At the same power consumption as a 7nm chip, a 5nm one will run 15% faster. At the same performance level, a 5nm chip will consume 30% less power than a 7nm one. And the 5nm node is reported to have better yield rates, too.

Image credit: Laura Ockel

https://www.techspot.com/news/86813-analysts-believe-single-tsmc-5nm-wafer-costs-17000.html