Why it matters: Moore's Law used to state that the number of transistors that could be squeezed on a chip would double every year. Later that was changed to every two years, but in 2016 manufacturers hit a wall. Moore's Law has been stalled or at least slowed, and new innovations are needed to reignite it. Chiplets might be the answer.

Moore's Law has been flagging for several years now. Transistors cannot get much smaller. The end of the paradigm is in sight, and it is bad news for chip manufacturers as that is what has driven chip sales for decades now.

"We're seeing Moore's law slowing," AMD's CTO Mark Papermaster recently told Wired. "You're still getting more density, but it costs more and takes longer. It's a fundamental change." So foundries are scrambling for new ways to extend the cycle and continue bringing more powerful processors to the market. After all, what is the point of getting the latest and greatest processor or PC if it doesn't offer any more power than the one already sitting on your desk?

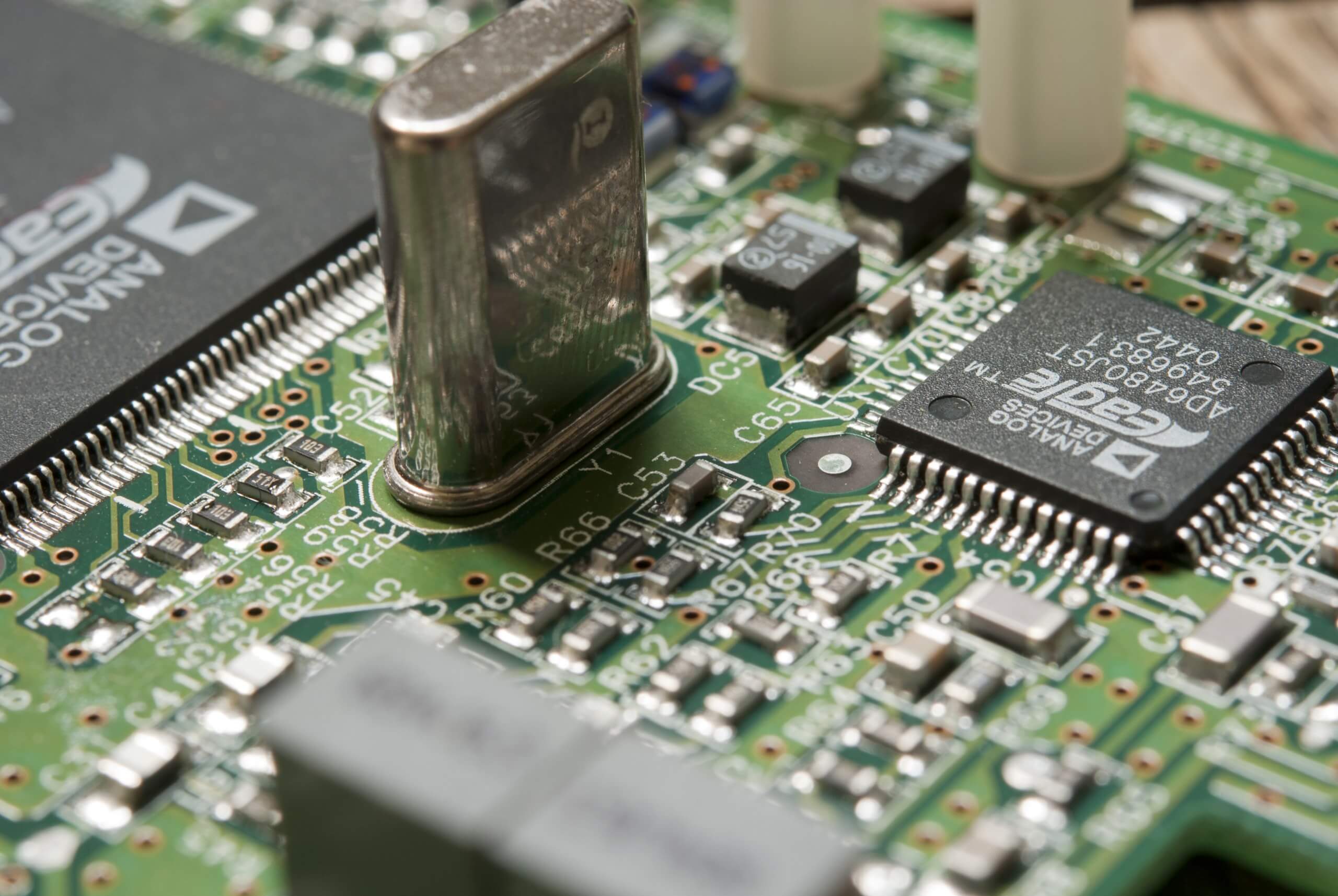

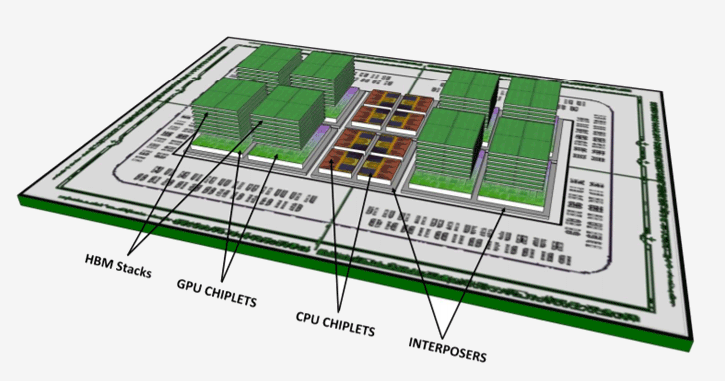

One of the newer ideas is something being referred to as "chiplets." Chiplets are modular pieces of silicon that can be put together somewhat like Lego blocks. Instead of printing a whole circuit on a single chip, a number of chiplets can be put together in various configurations allowing multi-die processors tailored for specific tasks such as machine learning or cloud computing.

Both AMD and Intel believe that the industry is moving in this direction because it allows them to quickly ship more powerful processors.

"[It's] an evolution of Moore's law," said Ramune Nagisetty, a senior principal engineer at Intel.

The current processes of manufacturing the smallest transistors and chips are complicated and expensive. Chiplets could provide a way to continue building powerful processors with lower overhead and fewer flaws.

"The latest, greatest, and smallest transistors are also the trickiest and most expensive to design and manufacture with. In processors made up of chiplets, that cutting-edge technology can be reserved for the pieces of a design where the investment will most pay off. Other chiplets can be made using more reliable, established, and cheaper techniques. Smaller pieces of silicon are also inherently less prone to manufacturing defects."

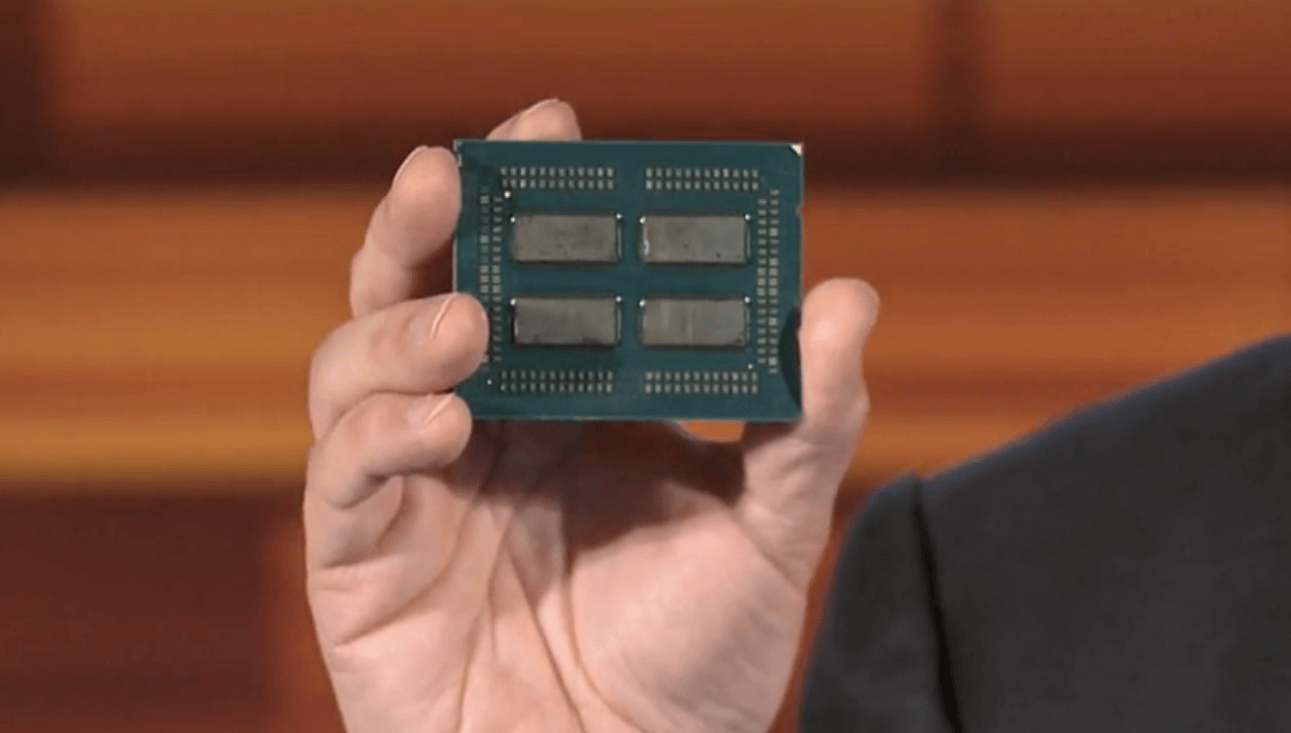

Chiplets are not just in the future of processor fabrication --- they are already here. Last year AMD tested this approach with a server processor called Epyc. Epyc was comprised of four chiplets, and AMD engineers estimate that if they had tried to make it as a single large chip, it would have at least doubled the manufacturing cost.

"Intel has a very deep roadmap for chiplets. This is the future."

The success of Epyc is apparent since earlier this week AMD announced it would be producing a second-generation of Epyc server processor that would be made from eight chiplets (64 cores), effectively doubling its power.

Intel has also been working with the modular design idea. It is designing processors for laptops that combine an Intel CPU with a "custom-designed graphics module from AMD." It marks the first time Intel has used a core from another manufacturer in its own main-line processors.

"Combining the components chiplet-style allows them to work together more closely than if the graphics processor were a separate component," said Nagisetty.

The chip is already being used in notebooks from HP and Dell, and future generations are already on the drawing board.

The Pentagon is also interested in this new process and has committed $1.5 billion to further research in the area through DARPA's Electronic Resurgence Initiative. Universities, defense contractors, and chip foundries will receive grants through the program to advance chiplet technology. DARPA is also looking to come up with a standard that will allow modules from different manufacturers to work together. Intel has already agreed to produce a "royalty-free interconnect technology" for its chiplets.

As this modular approach to processor manufacturing continues, it will be interesting to see how the rest of the industry adapts to the new architectures, and whether it can extend Moore's Law in the years to come.